Dek . 11, 2024 11:09 Back to list

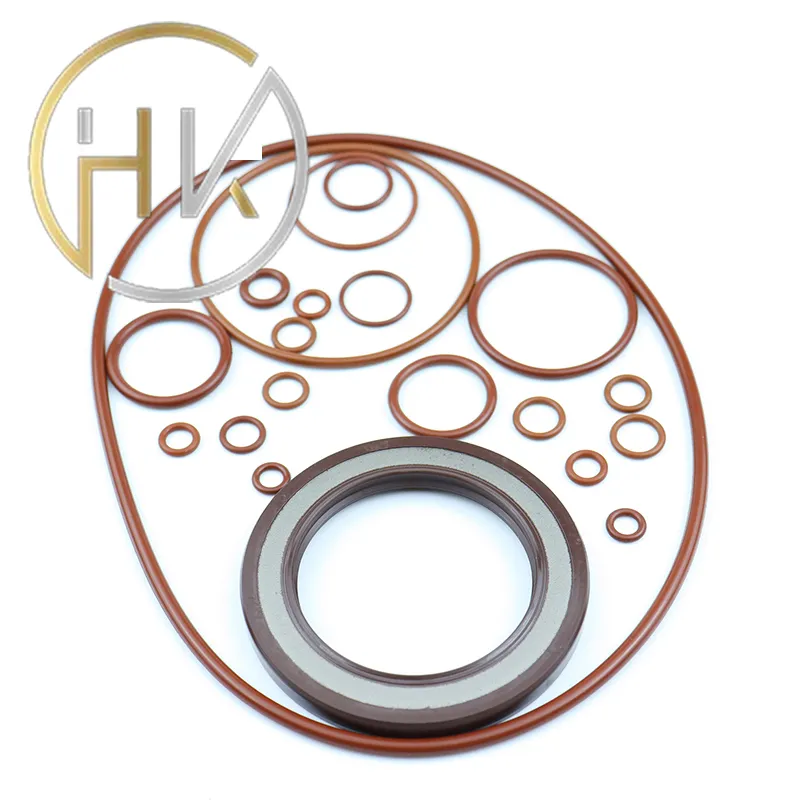

wheel oil seal

Understanding Wheel Oil Seals Importance and Functionality

Wheel oil seals, often overlooked in vehicle maintenance discussions, play a crucial role in ensuring the longevity and performance of various types of machinery, especially in automobiles. These seals are designed to prevent the leakage of lubricants, which are critical for the smooth operation of moving parts. In essence, they maintain the integrity of the lubricant environment, ensuring that components are well-lubricated and protected from dirt and debris.

The Role of Wheel Oil Seals

Wheel oil seals are specifically positioned in the wheel assembly of vehicles. Their primary function is to keep the lubrication oil or grease within the wheel bearings while preventing contaminants from entering the assembly. This sealing capability is essential because wheel bearings operate under significant load and heat, requiring adequate lubrication to minimize friction and wear.

A typical oil seal consists of a rubber or synthetic material with a metal casing. The design includes a lip that applies pressure against the surface it’s sealing to create a tight barrier. This configuration helps to prevent oil from seeping out, which could lead to serious mechanical failures if left unchecked.

Types of Wheel Oil Seals

There are various types of wheel oil seals, tailored to meet different requirements

1. Static Seals These seals are used in components that do not have movement. They provide a barrier against oil leakage and contamination. 2. Dynamic Seals These seals are designed to accommodate moving parts. They adapt to the movements within the assembly while maintaining a tight seal to prevent lubrication loss.

3. Single Lip Seals and Double Lip Seals Single lip seals are more common and adequate for many applications. However, double lip seals provide an additional layer of protection against contamination and oil loss, making them suitable for more demanding environments.

wheel oil seal

Importance of Regular Maintenance

Neglecting the condition of wheel oil seals can lead to dramatic consequences

. Over time, seals can wear out due to exposure to high temperatures, friction, or chemical degradation from the lubricants themselves. A worn oil seal can result in grease leakage, which can cause the bearings to operate dry. This scenario not only increases wear and tear but also raises the risk of catastrophic failure, which could compromise the safety and performance of the vehicle.Regular inspection and timely replacement of wheel oil seals can prevent these issues from arising. Maintenance procedures should include checking for signs of oil leakage, inspecting the condition of the seals, and ensuring that they are properly seated in their designated grooves.

Signs of Seal Failure

Identifying the early signs of wheel oil seal failure is key to avoiding larger issues. Common indicators include

- Oil spots or puddles beneath the vehicle. - Unusual noises coming from the wheels, such as grinding or rumbling sounds. - Excessive heat in the wheel assembly, which can be felt by touch. - Vibrations during driving, indicating potential wheel bearing failures.

If any of these symptoms are present, it is essential to have the vehicle inspected by a qualified mechanic who can assess the condition of the wheel oil seals and recommend appropriate actions.

Conclusion

In summary, wheel oil seals may seem like minor components, but their impact on vehicle performance, longevity, and safety is significant. Regular maintenance and prompt attention to any signs of seal degradation can save vehicle owners from costly repairs and ensure a smooth, safe driving experience. Understanding the role and importance of wheel oil seals is crucial for anyone looking to maintain their vehicle in optimal condition.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories