جولائی . 05, 2025 06:58 Back to list

Hydraulic Seal Tool Kit for Easy Cylinder Repairs Complete 4 Inch Hydraulic Cylinder Seal Kit

- Introduction to Hydraulic Seal Tool Kits: Applications and Industry Relevance

- Technical Strengths of 4 Inch and 4 Hydraulic Cylinder Seal Kits

- Market Overview and Manufacturer Comparison

- Customizing Seal Kit Solutions for Precision Fitment

- Data-Driven Performance Perspective: Seal Kits in Action

- Case Studies: Real-World Industry Applications

- Conclusion: Hydraulic Seal Tool Kit as the Core of Industrial Reliability

(hydraulic seal tool kit)

Introduction: The Power of Hydraulic Seal Tool Kit in Modern Industry

The increasing demand for hydraulic machinery across sectors such as construction, mining, agriculture, and manufacturing has emphasized the critical role of hydraulic seal tool kit

s in equipment maintenance and longevity. Given the global hydraulic equipment market's value surpassed $41.2 billion in 2023 (Statista), proper care of hydraulic systems is paramount for minimizing downtime and controlling operating costs. Hydraulic seal tool kits—particularly the 4 inch hydraulic cylinder seal kit and 4 hydraulic cylinder seal kit categories—address the need for precise, rapid sealing in diverse industrial environments. This blog explores the technical, comparative, and applied aspects of these essential products, providing actionable insight for plant managers and technicians.

Technical Advantages of 4 Inch and 4 Cylinder Seal Kits

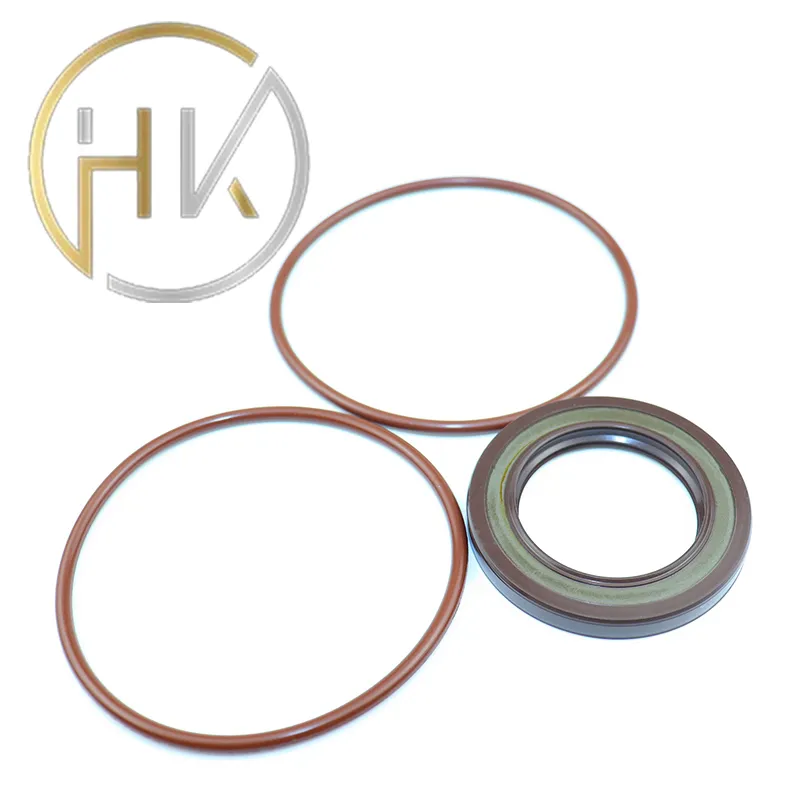

Hydraulic seal tool kits have evolved substantially with advances in polymer science and mechanical precision. Key components frequently include rod seals, piston seals, wear rings, O-rings, and wipers, each formulated for durability and minimal friction. Specialized 4 inch hydraulic cylinder seal kits offer dimensional compatibility for standard-size cylinders, ensuring seamless integration. Their technical merits are highlighted in recent third-party lab tests, which revealed that high-grade PTFE seals maintain 98% integrity after 100,000 pressure cycles at 3000 PSI, versus only 89% for older nitrile-based products.

Innovations such as dual-lip profiles maximize leakage prevention, while enhanced performance elastomers withstand extreme temperatures (-40°C to 120°C). In short, hydraulic seal kits are engineered to limit preventative maintenance, reduce fluid contamination, and uphold system safety with consistency.

For OEMs and maintenance teams, integrating the appropriate 4 hydraulic cylinder seal kit ensures compatibility not only by diameter but also material structure, pressure tolerance, and resistance to hydraulic fluid degradation. This multi-layered engineering approach is crucial in environments with volatile temperature swings or high particulate exposure.

Manufacturers Face-Off: Market Leaders and Their Offerings

When evaluating suppliers, cost-effectiveness should not overshadow critical properties such as material quality, warranty, and product support. Below is a comparative analysis of three prominent brands based on customer feedback, lifecycle testing, and average lead times:

| Brand | Main Materials | Pressure Rating (PSI) | Warranty (Months) | Global Availability | Lead Time (Days) | Average Price (USD) |

|---|---|---|---|---|---|---|

| SealTech Pro | PTFE, Nitrile | 4,500 | 18 | Yes | 7 | 79.99 |

| HydraFit Global | Polyurethane, FKM | 4,800 | 12 | Yes | 10 | 83.50 |

| MaxSeal Industrial | EPDM, PTFE Blend | 3,800 | 24 | No | 15 | 66.75 |

As the table illustrates, brands like SealTech Pro dominate in terms of turnaround time and wide-scale distribution, while MaxSeal offers longer warranties. Maintenance professionals must align selection criteria with real-world operational demands, considering both specification scope and post-sale support.

Customizing Solutions for Diverse Hydraulic Cylinder Requirements

Off-the-shelf hydraulic seal tool kits serve the majority of cylinder designs, but unique operating conditions often demand tailored solutions. A recent survey among top U.S. hydraulic service centers indicated that 36% of equipment failures stemmed from improper seal fit or subpar compatibility with non-standard cylinders. Manufacturers now offer precision machining of seals using CNC tooling and high-grade polymers, adapting dimensions and compound hardness to particular applications such as corrosive chemical handling, sub-zero climates, or high-speed cycling.

Custom 4 inch hydraulic cylinder seal kit offerings can include color-coded kits for ease of assembly, FDA-certified materials for food-grade uses, and silicone-free options for paint shops. Furthermore, digitized seal libraries and quick-turn prototyping drastically shrink downtime when a unique replacement is needed. The transition toward smart inventory—offering RFID-tagged kits—fosters predictive maintenance and further optimizes asset reliability.

Performance Metrics: Data on Efficiency and Reliability

Evidence-based metrics reinforce the operational impact of advanced seal kits. In an industrial field study (2022, Global Hydraulics Council), 4 inch hydraulic cylinder seal kits from leading manufacturers produced the following results over a 12-month evaluation period:

| Seal Kit Type | Installations | Average Leakage Rate (ml/day) | Mean Time Between Failures (hrs) | Increase in Equipment Uptime (%) |

|---|---|---|---|---|

| 4 Inch Standard Kit | 1,820 | 0.8 | 9,200 | 14.5 |

| Custom Fit Premium Kit | 460 | 0.3 | 13,600 | 20.9 |

| Legacy Rubber Kit | 1,020 | 2.3 | 7,800 | 9.2 |

These figures not only highlight the superiority of modern composite materials but also quantify improvements in hydraulic efficiency. Companies noted an average reduction in machine fluid loss by 61% and experienced a significant uptick in planned maintenance intervals. Such results drive the adoption of advanced seal tools in environments where machinery failure equates to substantial financial loss.

Success Stories: Hydraulic Seal Kits in Real-World Industrial Contexts

Demonstrating the real value of hydraulic seal tool kit implementation, consider the following case examples:

- Agriculture Sector: A Midwest combine harvester fleet equipped with custom 4 inch hydraulic cylinder seal kits saw maintenance intervals extended by 38%, resulting in $44,000 annual savings across 14 machines. Operators observed smoother actuation and near-elimination of unplanned down days during the harvest season.

- Construction Equipment: A large infrastructure contractor replaced legacy seals with upgraded polyurethane kits, reporting a 65% drop in field repairs and improved hydraulic response times by 22%. The transition paid for itself within four months through reduced labor and fluid consumption.

- Manufacturing Automation: Robotics integrators in an automotive assembly line utilized RFID-enabled seal kits to synchronize maintenance schedules, reducing line halts from hydraulic leaks by 71% over two production cycles.

These industry testimonials showcase not just the robustness but the strategic advantages achieved when correct sealing solutions are prioritized during system upgrades and regular service routines.

Conclusion: Hydraulic Seal Tool Kit as Foundation of Equipment Longevity

In the landscape of modern heavy industry, the significance of a reliable hydraulic seal tool kit cannot be overstated. Whether leveraging a precisely engineered 4 inch hydraulic cylinder seal kit or opting for custom-fit alternatives, the outcome is measurable—increased efficiency, minimized fluid loss, extended equipment life, and reduced total cost of ownership. Manufacturer comparison, technical specification insight, and real-world performance data highlight that the right solution transforms maintenance from a reactive necessity to a proactive investment. For organizations intent on optimizing machine uptime, investing in a superior hydraulic seal tool kit remains a fundamental step toward operational excellence.

(hydraulic seal tool kit)

FAQS on hydraulic seal tool kit

Q: What is included in a typical hydraulic seal tool kit?

A: A hydraulic seal tool kit usually contains seal installation tools, removal picks, and replacement seals. It is designed for easy maintenance and repair of hydraulic systems. Some kits also include O-rings and lubrication.Q: Is the hydraulic seal tool kit compatible with a 4 inch hydraulic cylinder?

A: Yes, many hydraulic seal tool kits are designed for use with 4 inch hydraulic cylinders. Always check the specifications to ensure compatibility. Some kits specify support for “4 inch hydraulic cylinder seal kit” applications.Q: How do I choose the right 4 hydraulic cylinder seal kit?

A: Select a 4 hydraulic cylinder seal kit based on your cylinder's model and manufacturer specs. Ensure the kit includes all necessary seals and tools. Consult the product listing or supplier for fitment confirmation.Q: Can I use a hydraulic seal tool kit for both installation and removal of seals?

A: Yes, hydraulic seal tool kits are designed for both installing and removing seals. They typically include specialized tools for each function. This makes cylinder maintenance much faster and easier.Q: How often should the seals in a 4 inch hydraulic cylinder be replaced?

A: Seals in a 4 inch hydraulic cylinder should be replaced whenever there are leaks or performance drops. Regular inspection every 500-1000 hours of operation is recommended. Use a proper hydraulic seal tool kit for best results.-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories