دسمبر . 01, 2024 05:31 Back to list

Exploring the Features and Benefits of 32x47x7mm Seals for Various Applications

The Versatility of the 32x47x7 Seal A Vital Component in Modern Mechanics

In the vast realm of mechanical engineering and design, every component plays a crucial role in ensuring efficiency and longevity. Among these components, seals have emerged as essential elements that aid in preventing leakage, contamination, and loss of performance. One of the most widely used seals in various applications is the 32x47x7 seal, known for its precise dimensions and robust functionality.

Understanding the 32x47x7 Seal

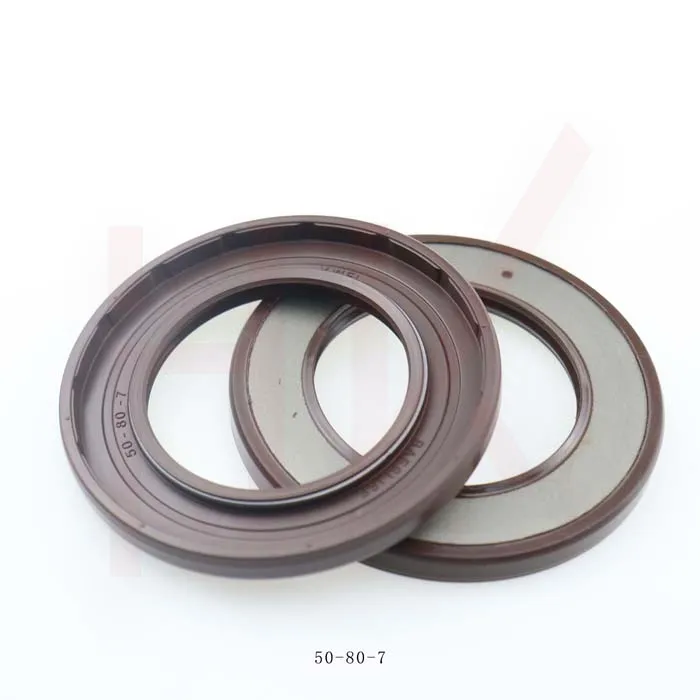

The 32x47x7 designation refers to the seal's dimensions in millimeters a 32 mm inner diameter, a 47 mm outer diameter, and a 7 mm thickness. These specifications make it suitable for a range of applications, particularly in automotive and industrial machinery. The seal itself is designed to fit snugly into a designated groove, creating a barrier that protects components from external contaminants while retaining essential lubricants.

Applications of the 32x47x7 Seal

1. Automotive Industry The automotive sector is one of the primary users of the 32x47x7 seal. It is often found in engine components, transmission systems, and differentials, where it helps to prevent oil and fluid leaks. Its ability to withstand high temperatures and pressures makes it particularly suitable for these demanding environments.

2. Industrial Machinery In manufacturing, equipment such as pumps, gearboxes, and hydraulic systems relies on seals to ensure efficient operation. The 32x47x7 seal is pivotal in these systems, providing a reliable barrier against contaminants that could lead to wear and tear, thus prolonging the life of the machinery.

3. Aerospace Engineering In the aerospace sector, precision is paramount. The 32x47x7 seal is designed to adhere to strict industry standards, ensuring safety and reliability in various aircraft components. Its lightweight yet durable design helps maintain fuel efficiency while ensuring that critical systems remain sealed and operational.

32x47x7 seal

Material Composition

The effectiveness of the 32x47x7 seal is largely attributed to its material composition. Most seals are made from elastomers like nitrile rubber (NBR), fluorocarbon rubber (FKM), or silicone, which offer durability and flexibility. These materials are chosen based on the specific environmental conditions they will face, such as exposure to extreme temperatures, chemicals, or moisture. For instance, in situations where the seal will encounter oil and gasoline, NBR is often used due to its excellent resistance to these substances.

Maintenance and Replacement

While seals like the 32x47x7 are designed for longevity, regular maintenance is crucial to ensuring optimal performance. Inspecting seals for signs of wear, such as cracks, distortion, or hardness, can prevent unexpected failures. In an industrial setting, it is advisable to conduct periodic checks as part of a preventive maintenance schedule.

When replacement is necessary, it is important to ensure the new seal is fitted correctly. A poorly installed seal can lead to leaks and ultimately, equipment failure. Moreover, ensuring that the sealing surface is clean and undamaged is critical to prolonging the new seal's life.

Conclusion

In conclusion, the 32x47x7 seal is a small but vital component that plays a monumental role in various industries, from automotive to aerospace. Its design, material composition, and functionality ensure that it meets a wide range of demands, making it a staple in machinery and equipment production. As technology advances and industries evolve, the importance of high-quality seals like the 32x47x7 will only continue to grow, underscoring the significance of maintenance, proper installation, and timely replacement. By understanding and appreciating the intricate workings of seals, engineers and technicians can enhance the reliability and efficiency of the systems they work on, paving the way for innovation and progress in modern engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories