Сер . 06, 2025 03:40 Back to list

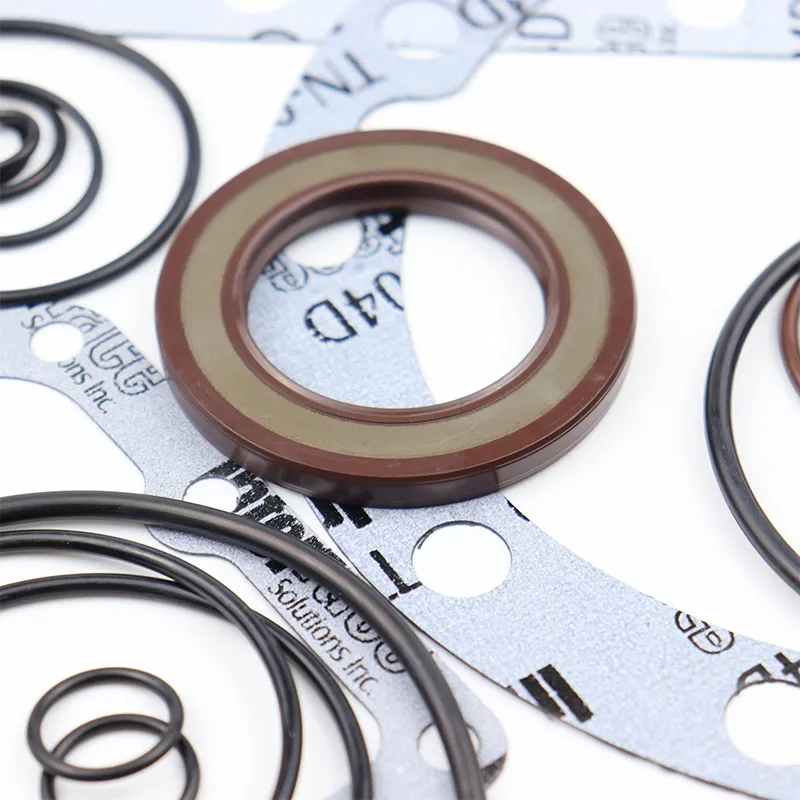

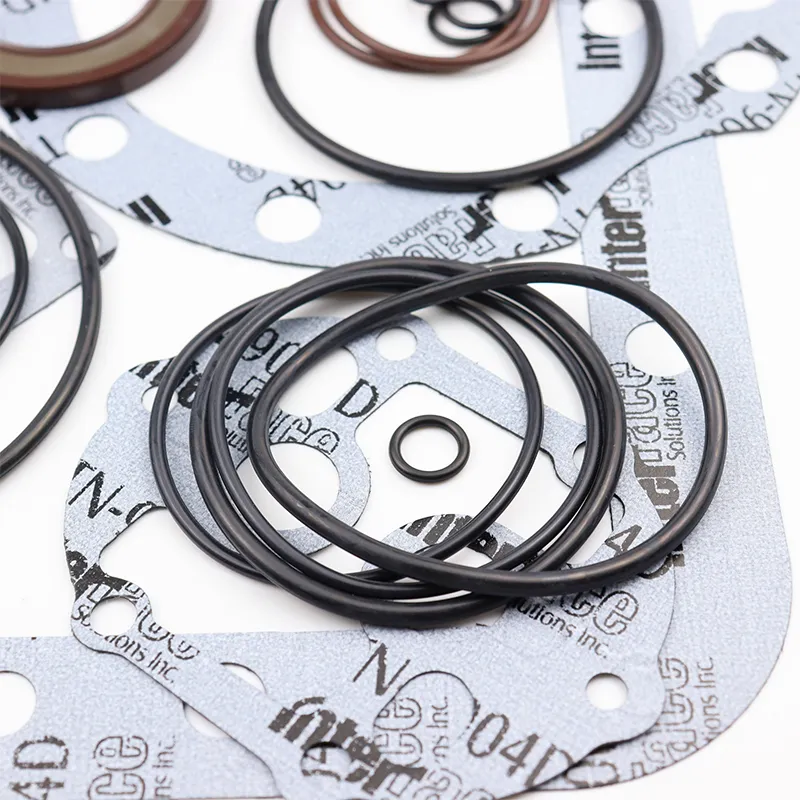

PV23 Motor Repair Kit | Hydraulic Pump Oil Seal Kit

The Critical Role of Sealing in Modern Hydraulic Systems: Industry Trends

The global hydraulic pump market is projected to reach USD 12.5 billion by 2027, growing at a CAGR of 3.8%. This growth is fueled by increasing mechanization in agriculture, construction, and mining. Within this expanding market, the Maintenance, Repair, and Overhaul (MRO) segment plays a pivotal role. Effective maintenance is no longer a cost center but a strategic advantage, directly impacting equipment lifespan, operational safety, and profitability. A leaking hydraulic system can lose up to 20% of its efficiency, leading to significant energy waste and potential environmental contamination. Consequently, the demand for high-quality, reliable repair components like the Hydraulic pump motor oil seal repair kit PV23 motor repair kit has never been higher.

Modern trends show a clear shift towards advanced materials. Standard Nitrile (NBR) seals are being replaced by high-performance elastomers like Fluorocarbon (FKM/Viton®) and Polytetrafluoroethylene (PTFE) to cope with higher operating temperatures, aggressive synthetic fluids, and extreme pressures. Our PV23 motor repair kit is at the forefront of this trend, utilizing materials that meet and exceed OEM specifications to ensure superior performance and longevity.

Technical Deep Dive: Anatomy of the PV23 Motor Repair Kit

The Hydraulic pump motor oil seal repair kit PV23 motor repair kit is not merely a collection of O-rings; it is a comprehensive, precision-engineered solution designed to restore the integrity of Sauer-Danfoss PV23 series hydraulic motors. Each component is manufactured to strict tolerances to ensure a perfect fit and prevent the primary causes of hydraulic failure: internal and external leakage. Understanding its technical specifications is key to appreciating its value.

Core Technical Specifications

| Parameter | Specification | Significance & Impact |

|---|---|---|

| Product Name | Hydraulic pump motor oil seal repair kit PV23 motor repair kit | Specifically designed for PV23 series motors, ensuring compatibility and optimal performance. |

| Primary Seal Material | Fluorocarbon (FKM/Viton®) | Excellent resistance to high temperatures (-20°C to +200°C), petroleum oils, synthetic fluids, and chemicals. |

| Secondary Seal Material | Nitrile (NBR), PTFE, Polyurethane (PU) | Components are chosen for specific functions: NBR for flexibility, PTFE for low friction, PU for abrasion resistance. |

| Maximum Pressure Rating | Up to 40 MPa (5800 PSI) | Capable of withstanding the high-pressure spikes common in heavy-duty hydraulic applications. |

| Hardness (Durometer) | 70-90 Shore A | Optimized balance between sealing force and resistance to extrusion and wear. |

| Compliance Standard | ISO 9001, ASTM D2000 M2HK810 | Guarantees manufacturing quality and material performance according to international standards. |

| Applicable Industries | Construction, Mining, Agriculture, Forestry, Metallurgy | Versatile and robust enough for the most demanding operational environments. |

| Estimated Service Life | Exceeds 5,000 operational hours under standard conditions | Reduces frequency of repairs and associated downtime, leading to lower total cost of ownership. |

Our Meticulous Manufacturing Process

The reliability of our Hydraulic pump motor oil seal repair kit PV23 motor repair kit stems from a rigorous, multi-stage manufacturing process that combines advanced technology with stringent quality control. Each step is critical to delivering a product that instills confidence and performs flawlessly.

1. Material Selection

Sourcing premium-grade FKM, NBR, and PTFE compounds from certified suppliers. Materials are tested for tensile strength, elongation, and chemical compatibility.

2. Precision Molding

Utilizing state-of-the-art compression and injection molding machines to form seals with tolerances as tight as ±0.05mm. Curing parameters are computer-controlled for consistency.

3. CNC Machining

For components like backup rings and metal-clad wipers, high-speed CNC lathes and mills ensure perfect geometry and surface finish, crucial for dynamic sealing.

4. Quality Control

100% visual inspection and dimensional checks using laser micrometers and optical comparators. Batch testing for hardness and compression set per ISO standards.

5. Assembly & Packaging

Kits are assembled in a clean-room environment, vacuum-sealed to protect from contamination and UV degradation, ensuring maximum shelf life.

Data-Driven Performance: Visualizing the Superiority

We believe in transparency and proof. The following visualizations demonstrate the superior performance and composition of our Hydraulic pump motor oil seal repair kit PV23 motor repair kit compared to industry averages and competitors.

Manufacturer Comparison: Key Performance Metrics

Material Composition of the HKAISAL PV23 Kit

FKM Seal Performance: Service Life vs. Operating Temperature

Application Scenarios & Technical Advantages

The versatility of the Hydraulic pump motor oil seal repair kit PV23 motor repair kit allows it to excel in a wide array of demanding environments. Its robust design is not a one-size-fits-all solution, but a targeted remedy for the challenges faced in various heavy industries.

- Construction Machinery (Excavators, Loaders): In the high-cycle, high-pressure world of construction, our kit prevents leaks in the swing and travel motors, ensuring precise control and preventing costly downtime on the job site. The FKM material's resistance to abrasion from dust and debris is a key advantage.

- Agricultural Equipment (Combines, Tractors): During planting and harvest seasons, equipment reliability is non-negotiable. Our seal kit ensures hydraulic systems for steering, lifting, and power transmission operate flawlessly, resisting degradation from hydraulic fluids and extreme weather conditions.

- Mining & Quarrying (Drill Rigs, Haul Trucks): These are some of the harshest operating conditions on earth. Our kit provides superior sealing performance against contaminants and high-pressure surges, crucial for the safety and productivity of multi-million dollar assets.

- Metallurgy and Steel Mills: The high-temperature environment of a steel mill degrades standard seals rapidly. The exceptional thermal stability of our FKM seals (up to 200°C) provides a significantly longer service life, reducing maintenance intervals in critical systems like furnace loaders and rolling mill hydraulics.

Core Technical Advantages:

- Energy Efficiency: By eliminating internal and external leaks, the hydraulic system maintains optimal pressure without the pump working overtime, leading to measurable fuel and energy savings.

- Enhanced Durability & Lifespan: The use of premium FKM and engineered PTFE extends the life of the seals far beyond standard NBR kits, resulting in a lower total cost of ownership.

- Superior Corrosion & Chemical Resistance: Our seals are virtually immune to modern synthetic and biodegradable hydraulic fluids, as well as oxidation and weathering, preventing premature failure.

- Reduced Downtime: A reliable seal kit means fewer unplanned maintenance events. By choosing our Hydraulic pump motor oil seal repair kit PV23 motor repair kit, you are investing in uptime and productivity.

Case Study: Restoring a CAT 320D Excavator's Swing Motor

Client: Major Construction Fleet Operator in the American Midwest.

Problem: A Caterpillar 320D excavator was experiencing a sluggish and weak swing function, coupled with a noticeable hydraulic fluid leak from the swing motor housing. The machine, with 8,500 operating hours, was suffering from significant downtime, impacting project timelines. Diagnosis pointed to failed internal seals in the Sauer-Danfoss PV23-based swing motor.

Solution: Instead of a costly motor replacement (quoted at over $9,000), the client's maintenance team opted for a complete overhaul using our Hydraulic pump motor oil seal repair kit PV23 motor repair kit. The comprehensive nature of the kit ensured they had every required seal, O-ring, and backup ring for the job.

Results:

- Cost Savings: The repair cost was less than 10% of the price of a new motor.

- Performance Restored: After the overhaul, the swing motor's performance was restored to OEM specifications. The sluggishness was eliminated, and all leaks were resolved.

- Downtime Reduction: The repair was completed in 6 hours, returning the excavator to service the same day. The client reported over 1,500 subsequent hours of operation with zero related issues.

- Client Feedback: "The HKAISAL kit was a game-changer. The quality of the seals was visibly superior to the generic kit we used previously. It saved us thousands and got our key asset back in the field faster than we thought possible." - Lead Mechanic

Customization, Trust, and Authority: The HKAISAL Advantage

We understand that standard solutions may not fit every unique challenge. HKAISAL, with over 15 years of expertise in the sealing industry, offers bespoke customization for the Hydraulic pump motor oil seal repair kit PV23 motor repair kit. Whether you require a special material compound for extreme cold (-40°C) or compatibility with a rare bio-fluid, our engineering team can develop a tailored solution.

ISO 9001 Certified Quality

Our manufacturing facilities adhere to the strict ISO 9001:2015 quality management system. This certification is your assurance of consistent quality, process control, and continuous improvement in every kit we produce.

Comprehensive Warranty

We stand behind our products. Every PV23 repair kit comes with a 12-month / 2,000-hour warranty against manufacturing defects, giving you complete peace of mind with your purchase and installation.

Expert Customer Support

Our support doesn't end at the sale. Our team of sealing experts is available to provide technical assistance, from installation queries to custom solution consultations. We are your partners in hydraulic maintenance.

Frequently Asked Questions (FAQ)

FKM (Fluorocarbon, often known by the brand name Viton®) is a high-performance elastomer used for the most critical seals in our kit, like the main shaft seal. Its key advantage is superior resistance to high temperatures (up to 200°C / 400°F) and aggressive chemicals, including synthetic hydraulic fluids. NBR (Nitrile Rubber) is an excellent general-purpose material used for static seals and O-rings where high temperatures are less of a concern. It offers great abrasion and tear resistance. We use a strategic combination to provide optimal performance at a competitive price point.

This kit is specifically designed for the Sauer-Danfoss PV23 series hydraulic motors. However, variations can exist based on the machine manufacturer (e.g., John Deere, Caterpillar, Komatsu). We strongly recommend cross-referencing the part number on your motor's data plate with our compatibility list. If you are unsure, please contact our technical support with your motor's model and serial number, and we will verify the correct kit for your application.

When stored correctly, our seal kits have an excellent shelf life. In accordance with ISO 2230 standards for rubber products, our vacuum-sealed packaging protects the seals from oxygen, ozone, and UV light. For FKM seals, the shelf life can exceed 10 years. For NBR components, it is typically 5-7 years. We recommend storing the kit in a cool, dry place away from direct sunlight and electrical equipment that can produce ozone.

Durometer is a standardized measure of a material's hardness. The "Shore A" scale is used for flexible rubbers and elastomers. A higher number indicates a harder material. A 90 Shore A seal is quite hard, making it highly resistant to being forced out of its groove under high pressure (a phenomenon called 'extrusion'). We select specific durometers for each seal in the Hydraulic pump motor oil seal repair kit PV23 motor repair kit based on its function—harder for high-pressure piston seals, slightly softer for more flexible wiper seals.

Absolutely. The kit is rated for continuous operating pressures up to 40 MPa (5800 PSI), with the ability to handle intermittent pressure spikes that are common in heavy machinery hydraulics. This is achieved through the use of high-durometer FKM seals paired with anti-extrusion backup rings made from materials like PTFE or hard plastic, which support the seal and prevent it from being damaged under extreme pressure.

While specific tools may vary, a standard installation would require a clean workspace, a set of metric wrenches and sockets, torque wrench, retaining ring pliers (internal and external), a soft-faced mallet, and a set of non-metallic seal picks (brass or plastic) to avoid scratching sealing surfaces. It is also crucial to have clean hydraulic fluid for lubrication during assembly and a lint-free cloth for cleaning components.

Yes. The materials used in our kits are specified and tested according to international standards. For example, our FKM material typically conforms to ASTM D2000 classification M2HK810, which defines its performance characteristics regarding heat resistance and oil swell. Our manufacturing process is governed by our ISO 9001:2015 certification, ensuring every kit meets a global benchmark for quality and consistency.

Authoritative References & Further Reading

Our commitment to excellence is grounded in established engineering principles and ongoing industry research. For those interested in a deeper understanding of hydraulic sealing technology, we recommend the following resources:

1. Industry Discussion: A thread on Heavy Equipment Forums discussing the nuances of hydraulic pump rebuilding and the importance of quality seal kits. Hydraulic Pump Rebuild Tips and Tricks - HeavyEquipmentForums.com

2. Scholarly Article: An in-depth analysis of elastomer seal failure modes in hydraulic systems. From "Tribology International," Volume 97, May 2016, Pages 255-265. "A review of the failure mechanisms of elastomer seals in hydraulic applications." ScienceDirect - Failure Mechanisms of Elastomer Seals

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories