Гру . 18, 2024 16:02 Back to list

hydraulic ram seal kit

Understanding Hydraulic Ram Seal Kits An Essential Component for Efficiency

Hydraulic systems are integral to a wide range of industries, powering everything from construction equipment to manufacturing machinery. Among the many components that make up these systems, hydraulic ram seal kits play a crucial role in ensuring efficiency, reliability, and longevity. This article delves into the importance of hydraulic ram seal kits, their components, and best practices for maintenance.

What is a Hydraulic Ram Seal Kit?

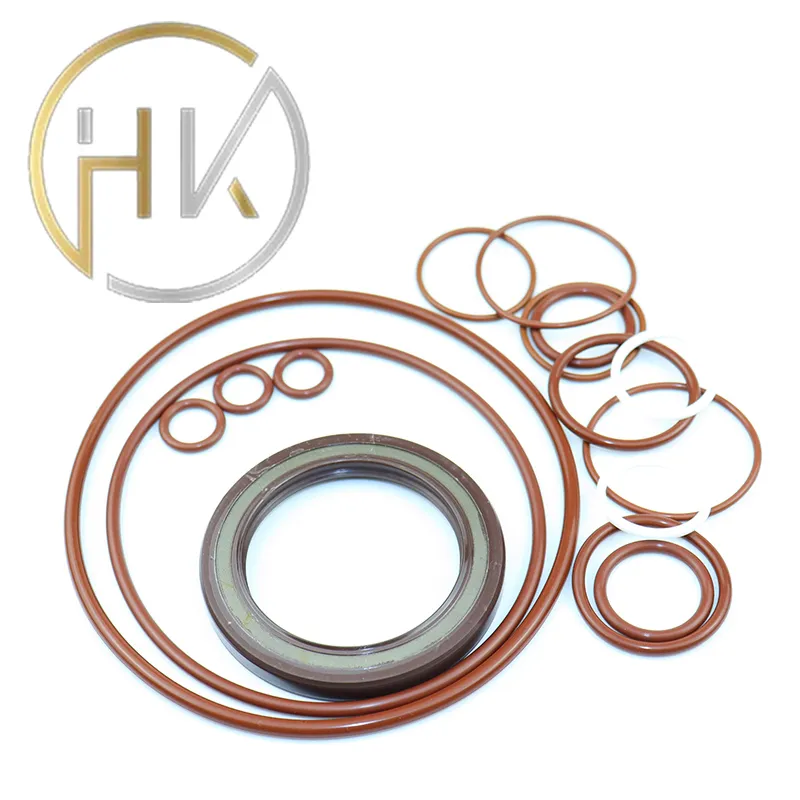

A hydraulic ram seal kit is a collection of seals specifically designed for hydraulic rams, which are devices that utilize hydraulic pressure to perform work. These rams are often found in applications such as lifting, pressing, and pushing. The seal kit typically includes various types of seals, such as O-rings, piston seals, rod seals, wiper seals, and backup rings, all crafted from materials that can withstand the pressure and conditions of hydraulic systems.

Importance of Hydraulic Ram Seal Kits

1. Preventing Leaks One of the primary functions of hydraulic seals is to prevent hydraulic fluid leaks. Leaks can lead to loss of pressure, resulting in decreased efficiency and performance of the hydraulic system. A properly functioning seal ensures that the hydraulic fluid remains contained, thereby maintaining the necessary pressure for optimal operation.

2. Maintaining System Integrity The integrity of the hydraulic system is paramount. Faulty seals can not only cause leaks but also allow contaminants to enter the system. This contamination can lead to component wear and failure, resulting in costly repairs and downtime. A well-maintained seal kit helps protect the internal components of the hydraulic ram, contributing to overall system health.

3. Extending Equipment Lifespan Regularly replacing worn seals with new ones from a hydraulic ram seal kit can significantly extend the lifespan of the hydraulic ram. This proactive maintenance approach minimizes the risk of damage to the hydraulic system, ultimately saving time and money.

Components of a Hydraulic Ram Seal Kit

Hydraulic ram seal kits can vary based on the manufacturer and specific application, but typically include

hydraulic ram seal kit

- Piston Seals These seals provide a tight fit around the piston, allowing for efficient movement within the cylinder. - Rod Seals Rod seals prevent hydraulic fluid from leaking out around the rod that extends and retracts from the cylinder. - Wiper Seals Positioned at the end of the cylinder, wiper seals help prevent dirt and debris from entering the hydraulic system. - O-Rings These versatile seals create a tight seal in various applications, proving effective against leaks under pressure. - Backup Rings These rings provide additional support to O-rings, preventing them from extruding or wearing prematurely.

Best Practices for Maintenance

To maximize the lifespan and performance of hydraulic ram seal kits, consider the following best practices

1. Regular Inspections Periodically inspect hydraulic rams for signs of wear or leaks. Early detection of issues can prevent larger problems down the line.

2. Replace Worn Seals Promptly When seals show signs of wear, such as cracking, hardening, or deformation, it's crucial to replace them immediately. Delaying replacement can lead to more significant issues.

3. Use Quality Seal Kits Always invest in high-quality seal kits from reputable manufacturers. Quality materials are essential in withstanding pressures and environmental conditions.

4. Proper Installation Ensure that seals are installed correctly. Improper installation can lead to premature failure and leaks.

5. Monitor Fluid Levels Maintaining the proper hydraulic fluid levels is essential. Low levels can cause overheating and increased wear on seals.

In conclusion, hydraulic ram seal kits are a vital component in maintaining the efficiency and reliability of hydraulic systems. By understanding their importance and implementing best practices for maintenance, operators can ensure their hydraulic equipment remains in optimal working condition for years to come.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories