ئۆكتەبىر . 30, 2024 21:46 Back to list

wheel oil seal

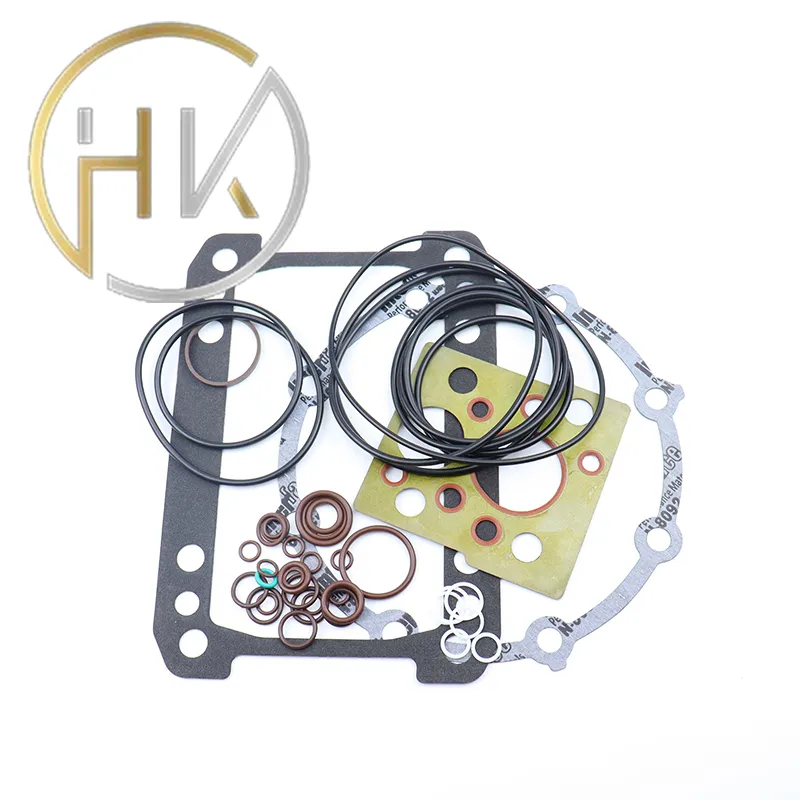

Understanding Wheel Oil Seals Importance and Functionality

Wheel oil seals, often overlooked in automotive maintenance, play a pivotal role in ensuring the smooth operation of a vehicle’s wheel assembly. These seals are crucial components that prevent lubrication from escaping and contaminants from entering the wheel bearings. Understanding the importance of wheel oil seals, their functionality, and maintenance can lead to improved performance and longevity of a vehicle.

At the core of every wheel assembly is the wheel bearing, which allows for smooth rotation of the wheel. Wheel oil seals are designed to keep the lubricating oil within the bearing while simultaneously keeping dirt, water, and other debris out. This dual function is essential because wheel bearings operate under significant stress and heat during driving. If the oil were to leak out, it could lead to increased friction, overheating, and ultimately, bearing failure.

Wheel oil seals are typically made from durable materials such as rubber or polyurethane. These materials are chosen for their resistance to wear, temperature fluctuations, and exposure to various chemicals found in automotive environments. The design of these seals is equally important; most have a lip that creates a tight seal against the surface of the bearing. This prevents oil from escaping and ensures that external contaminants do not penetrate the bearing assembly.

wheel oil seal

Regular maintenance of wheel oil seals is crucial for vehicle owners. Over time, seals can become brittle or worn due to atmospheric conditions, exposure to grease, and regular wear and tear. A compromised seal can lead to oil leaks, which may result in insufficient lubrication of the bearings. This can cause increased friction, leading to overheating and eventual bearing failure. Therefore, it is advisable to inspect wheel oil seals during routine maintenance intervals. Look for signs of wear, such as cracks or deformities in the rubber. If any issues are found, replacing the oil seal promptly can save you from more costly repairs in the future.

Replacing wheel oil seals is typically a straightforward procedure, but it requires precision. The old seal must be carefully removed, and the new seal should be installed without damaging the bearing or other components. It’s important to apply the correct amount of lubricant to ensure the new seal functions properly without leaking.

In conclusion, wheel oil seals are integral to the health of a vehicle’s wheel bearings and overall performance. Their main function of preventing oil leaks and protecting against contaminants is crucial for maintaining lubrication and minimizing friction. Regular inspection and timely replacement of worn seals can enhance a vehicle's efficiency and longevity. Therefore, understanding the role of wheel oil seals not only helps in the proper maintenance of a vehicle but also ensures safety on the road. Prioritizing the health of these small yet significant components can make a substantial difference in your vehicle's performance.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories