سېنتەبىر . 22, 2024 00:58 Back to list

tilt cylinder seal kit

Understanding Tilt Cylinder Seal Kits Importance and Functionality

Tilt cylinder seal kits play an essential role in the functionality and maintenance of hydraulic tilt cylinders, commonly found in various machinery, such as excavators, backhoes, and lifting equipment. These hydraulic components are vital for achieving controlled tilting motions, allowing for precise operations in construction, agriculture, and other heavy-duty applications. The integrity and performance of tilt cylinders largely depend on the quality and condition of the seal kits used.

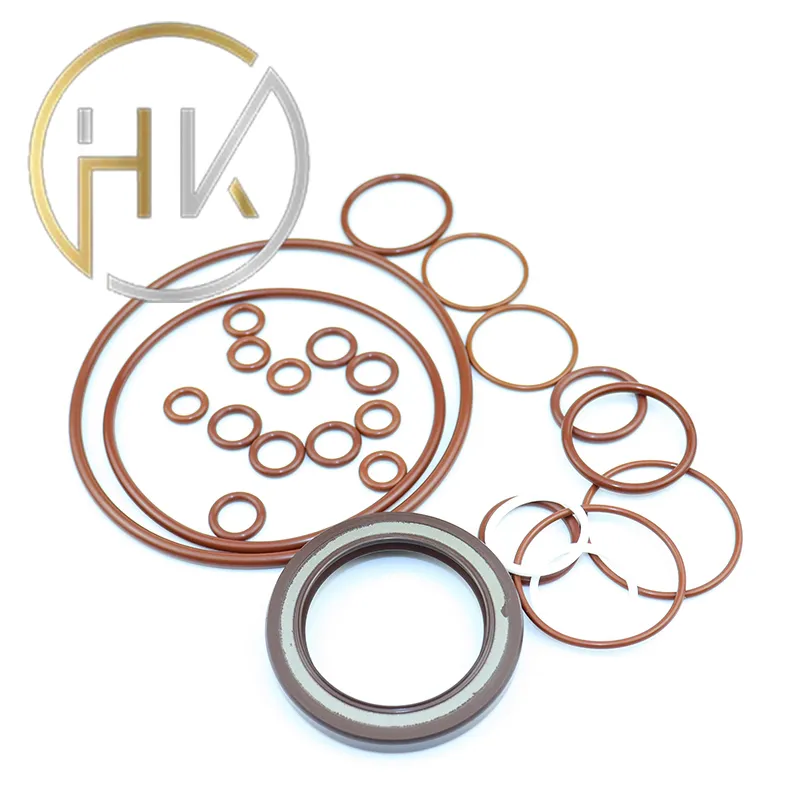

A tilt cylinder seal kit consists of several critical components, including O-rings, backup rings, and wear rings, designed to prevent hydraulic fluid leakage and maintain pressure within the cylinder

. The seals act as barriers, ensuring that the hydraulic fluid remains contained, which is crucial for the efficient operation of the cylinder. When the hydraulic fluid is pressurized, it creates the force needed to tilt the cylinder in either direction, enabling effective maneuverability of the machinery.Over time, seal kits can wear out due to constant movement, exposure to harsh environments, and the nature of hydraulic fluids. Common signs that a seal kit may need replacement include visible oil leaks around the cylinder, decreased performance in tilting functions, and unusual noises during operation. Regular inspections and timely replacements of these seal kits are essential to prevent more extensive damage, which can lead to costly repairs and downtime.

tilt cylinder seal kit

When selecting a tilt cylinder seal kit, it is crucial to consider several factors, including the compatibility with the specific tilt cylinder model, the materials used in the seal construction, and the operating environment. High-quality seal kits are typically made from durable materials like polyurethane or nitrile rubber, which provide excellent resistance to wear, temperature fluctuations, and chemical exposure.

Additionally, proper installation is vital for the optimal performance of the seal kit. Incorrect installation can lead to premature failure and inefficiencies in the hydraulic system. Therefore, following manufacturer guidelines and utilizing the right tools during installation are crucial steps that should not be overlooked.

In summary, tilt cylinder seal kits are essential for maintaining the functionality and efficiency of hydraulic tilt cylinders used in heavy machinery. Understanding their importance, recognizing signs of wear, and ensuring proper maintenance can lead to extended equipment life and improved operational capabilities. By selecting high-quality seal kits and adhering to proper installation practices, operators can enhance the performance of their machinery and reduce the risk of costly repairs. Investing in this aspect of equipment maintenance ultimately contributes to the overall productivity and longevity of the machinery involved.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories