ئۆكتەبىر . 10, 2024 06:11 Back to list

Hydraulic Ram Seal Kits for Optimal Performance and Maintenance Solutions

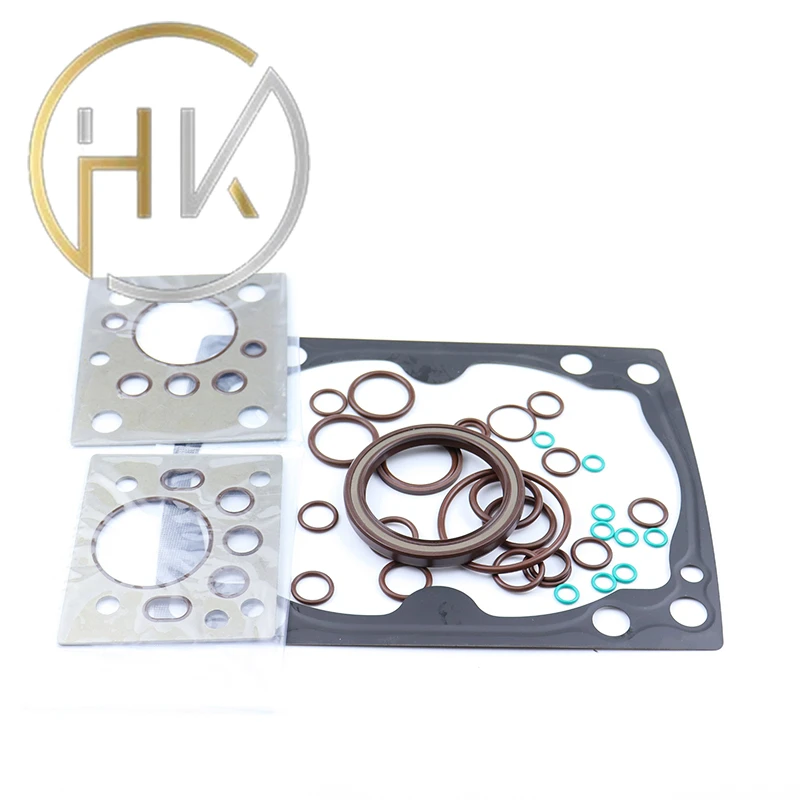

Understanding Seal Kits for Hydraulic Rams

Hydraulic rams are essential components in various industrial applications, from construction machinery to automotive systems. They rely on the power of hydraulic fluid to generate motion and force, making them vital for lifting, pushing, and manipulating heavy loads. However, the efficiency and longevity of hydraulic rams significantly depend on their seal systems, which is where seal kits come into play.

Understanding Seal Kits for Hydraulic Rams

One of the main advantages of using a seal kit is that it can significantly extend the life of a hydraulic ram. Over time, seals can wear out due to friction, heat, and exposure to various environmental conditions, such as dust and moisture. By regularly replacing old seals with a new kit, operators can prevent leaks that could lead to loss of hydraulic fluid, resulting in decreased performance and potential damage to the equipment. A well-maintained hydraulic ram, equipped with quality seal kits, can also operate at optimal efficiency, reducing downtime and maintenance costs.

seal kits for hydraulic rams

Moreover, selecting the right seal kit is crucial. Factors such as the fluid type, operating temperature, and pressure ratings should all be considered. Specialty seal kits are often available for different applications, ensuring compatibility and performance. Using the wrong size or type of seal can lead to premature failure and costly repairs.

Installation of seal kits is another important aspect to consider. Proper techniques and attention to detail during the installation process can prevent future issues. It is advisable to follow the manufacturer's guidelines and use the appropriate tools to ensure that seals are fitted correctly. Additionally, regular inspections and maintenance can help identify potential problems before they escalate, contributing to the longevity of the hydraulic ram.

In conclusion, seal kits are a vital element in maintaining the efficiency and reliability of hydraulic rams. They not only help prevent leaks and maintain pressure but also play a significant role in the overall performance of hydraulic systems. By investing in quality seal kits and adhering to proper maintenance practices, industries can enhance the performance and extend the service life of their hydraulic equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories