نويابىر . 17, 2024 00:37 Back to list

seal kit for pump

Understanding Seal Kits for Pumps A Comprehensive Guide

In the world of industrial machinery, pumps play a crucial role in numerous applications, from water supply to chemical processing. Just like any mechanical equipment, pumps require proper maintenance to ensure efficient operation and longevity. One essential component of pump maintenance is the seal kit. In this article, we will explore the importance of seal kits for pumps, their components, selection criteria, and the installation process.

What is a Seal Kit?

A seal kit for a pump typically consists of various seals and gaskets designed to prevent the leakage of fluids and maintain the integrity of the pump system. Seals are essential in keeping the pump operational by preventing the escape of fluid and protecting the internal components from contamination. Over time, seals can wear out due to factors such as heat, pressure, and exposure to chemicals, necessitating their replacement.

Importance of Seal Kits in Pump Maintenance

1. Leak Prevention The primary function of a seal kit is to prevent leaks. When seals are compromised, not only can fluid escape, leading to loss of efficiency, but it can also create hazardous situations, especially in chemical plants or wastewater treatment facilities.

2. Protection Against Contaminants Seals play a vital role in keeping external contaminants, such as dirt and debris, out of the pump's internal components. This is especially important in applications where pumps handle corrosive or particulate-laden fluids.

3. Enhanced Efficiency A properly sealed pump operates more efficiently by minimizing energy loss caused by leaks. Efficient pumps consume less energy, which is beneficial both economically and environmentally.

4. Longer Lifespan Regular maintenance, including seal replacement, can extend the life of a pump. Ignoring the condition of seals can lead to severe damage, requiring costly repairs or complete pump replacement.

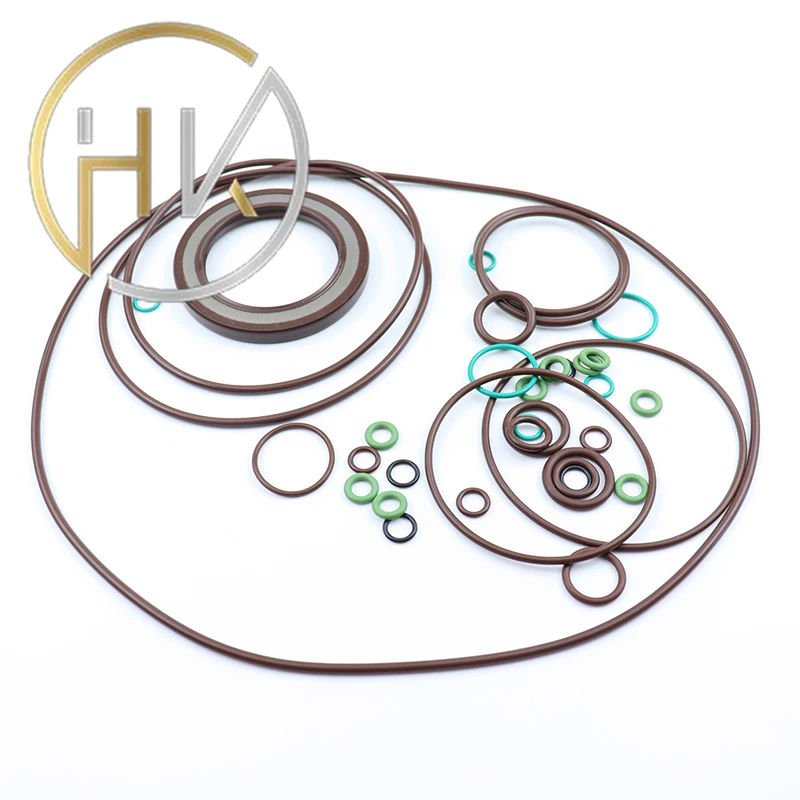

Components of a Seal Kit

Seal kits may vary depending on the type of pump and its application, but they typically include

- O-Rings Used to create a seal between two components, O-rings are essential for preventing leaks in static and dynamic applications.

- Lip Seals These are designed to seal rotating shafts and are crucial for preventing leakage along the shaft.

- Gaskets Gaskets provide a static seal between two flanged surfaces, preventing leaks in areas where two parts of the pump are joined.

- Back-Up Rings These assist O-rings and lip seals by providing additional support and preventing extrusion in high-pressure applications.

seal kit for pump

Selecting the Right Seal Kit

When selecting a seal kit for a pump, several factors need to be considered

1. Compatibility Ensure that the materials used in the seal kit are compatible with the fluids being handled by the pump. For instance, seals made from Viton are suitable for handling aggressive chemicals, while nitrile rubber works well with water and oils.

2. Temperature and Pressure Ratings Check the temperature and pressure ratings of the seals to ensure they can withstand the operational conditions of the pump.

3. Size and Configuration It’s important to choose a seal kit that matches the specific dimensions and configuration of your pump. This can usually be determined through the manufacturer’s specifications or identification plates.

Installation Process

Installing a seal kit requires attention to detail and some mechanical skill. Here’s a general outline of the process

1. Disassembly Start by carefully disassembling the pump. Pay attention to the order of parts for easier reassembly later.

2. Inspection Inspect all components for wear or damage. Replace any other worn parts as necessary.

3. Cleaning Clean all mating surfaces and remove old seal material to ensure a good fit for the new seals.

4. Installation Install the new seals according to the manufacturer’s instructions, ensuring they are seated properly and oriented correctly.

5. Reassembly Carefully reassemble the pump components in the reverse order of disassembly.

6. Testing Once reassembled, conduct a test run to check for leaks and ensure the pump operates smoothly.

Conclusion

Seal kits are a crucial aspect of pump maintenance, ensuring efficiency and preventing leaks. By understanding the components of seal kits and their importance, operators can make informed decisions that enhance the performance and longevity of their pumps. Regular maintenance, including the timely replacement of seals, not only protects the equipment but also optimizes operation, leading to significant savings in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories