دېكابىر . 20, 2024 11:36 Back to list

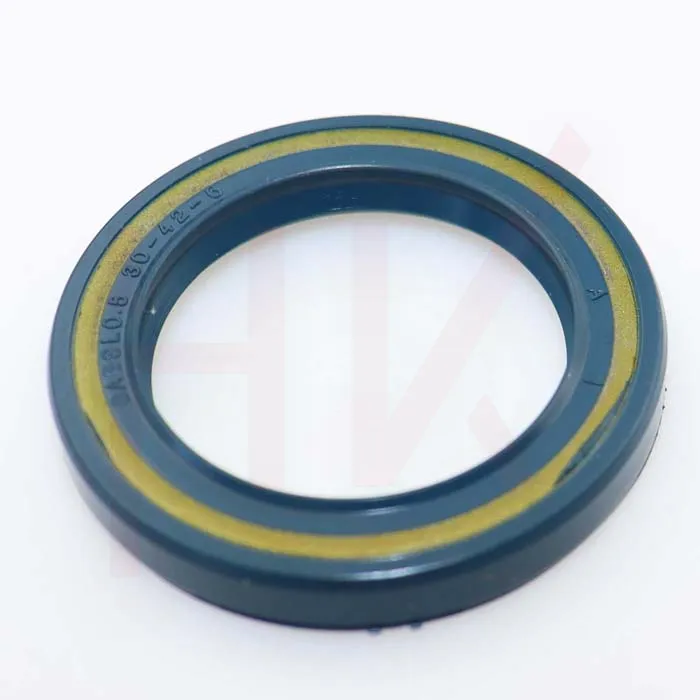

oil seal for motor

Understanding Oil Seals for Motors Essential Components for Efficient Performance

Oil seals, also known as rotary shaft seals, are crucial components in various machinery, particularly in motors. These seals are designed to prevent the leakage of lubricating oils and other fluids from the moving parts of a motor, ensuring efficient performance and longevity of the equipment. In this article, we will explore the functions, types, and importance of oil seals in motors.

Functions of Oil Seals

The primary function of an oil seal is to retain the lubricating oil within the motor while preventing contaminants such as dirt, dust, and moisture from entering the system. This is vital for several reasons

1. Lubrication Motors require proper lubrication to minimize friction and wear on moving parts. Oil seals help maintain the oil level, ensuring that all components receive adequate lubrication.

2. Contamination Prevention By keeping contaminants out, oil seals protect the motor components from premature wear and damage. Contaminated oil can lead to increased friction and overheating, jeopardizing the motor's performance.

3. Pressure Maintenance In many applications, maintaining pressure within the motor's oil system is critical. Oil seals contribute to this by creating a tight seal around the rotating shaft, minimizing the risk of pressure loss.

Types of Oil Seals

Oil seals come in various shapes, sizes, and materials, allowing for specific applications based on the motor's requirements. The common types include

1. Single Lip Seals These are the most basic type, featuring one sealing lip that contacts the rotating shaft. They are suitable for applications with low-pressure oil systems.

2. Double Lip Seals These seals have two lips, providing an additional layer of protection against leakage and contamination. They are ideal for high-pressure systems.

oil seal for motor

3. Spring-loaded Seals These seals include a spring that presses the lip against the shaft, ensuring a tighter fit and better sealing capabilities, especially in variable temperature environments.

4. Mechanical Seals Commonly used in high-performance applications, mechanical seals can withstand high pressures and temperatures, making them suitable for advanced motors.

Importance of Oil Seals in Motors

The significance of oil seals in motor performance cannot be overstated. Here are a few reasons why they are essential

1. Operational Efficiency When oil seals function correctly, motors run more efficiently, with reduced friction and heat generation. This leads to less energy consumption and improved performance.

2. Extended Service Life By preventing fluid leaks and protecting against contamination, oil seals contribute to the overall longevity of the motor. Well-sealed motors require less frequent maintenance and replacement.

3. Cost-Effectiveness Investing in quality oil seals can reduce downtime and repair costs. Preventing oil leaks means less frequent oil changes and lower chances of catastrophic failures, saving money in the long run.

4. Environmental Protection Properly functioning oil seals minimize the risk of environmental contamination due to leaks. This is particularly important for industries that comply with strict environmental regulations.

Conclusion

In summary, oil seals are vital components of motors that play a crucial role in their operation and maintenance. With various types available, it is essential to select the right seal for specific applications to ensure optimal performance and longevity. By understanding the functions and importance of oil seals, manufacturers and users alike can appreciate their role in sustaining efficient and reliable motor operations. Investing in quality oil seals not only enhances motor performance but also contributes to better environmental stewardship and cost savings over time.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories