نويابىر . 20, 2024 14:52 Back to list

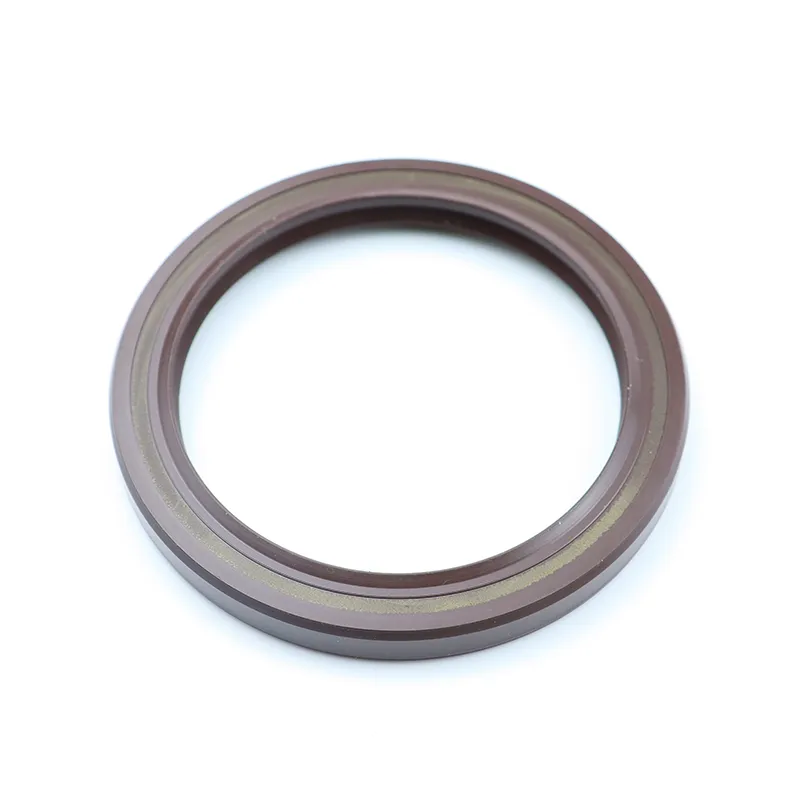

metal wiper seal

The Importance of Metal Wiper Seals in Industrial Applications

In the realm of industrial machinery and hydraulic systems, the significance of sealing solutions cannot be overstated. Among various sealing technologies, metal wiper seals stand out for their durability and efficiency. These seals are particularly vital in environments where contamination and fluid retention play crucial roles in maintaining operational integrity.

What is a Metal Wiper Seal?

A metal wiper seal is a type of sealing element designed to prevent the ingress of dirt, dust, and other external contaminants while also ensuring that hydraulic fluids remain contained within the system. Typically constructed from robust materials such as stainless steel or other high-strength alloys, metal wiper seals are engineered to withstand harsh operating conditions, including extreme temperatures and significant pressure variations.

Applications and Benefits

Metal wiper seals are commonly found in various applications, including hydraulic cylinders, pneumatic systems, and heavy machinery. Their primary function is to protect the main sealing components, such as O-rings and lip seals, from debris and abrasive particles that could compromise their performance. By acting as a first line of defense, these seals not only enhance the lifespan of the machinery but also reduce maintenance costs and downtime.

One of the most notable advantages of metal wiper seals is their ability to perform in demanding conditions. Unlike traditional rubber seals, which may degrade over time due to exposure to harsh chemicals or extreme temperatures, metal wiper seals maintain their structural integrity. This resilience ensures consistent performance even in applications where other materials might fail.

metal wiper seal

Design Considerations

The design of metal wiper seals is crucial for their effectiveness. Engineers must carefully consider factors such as lip geometry, seal material, and overall dimensions to ensure optimal functionality. The wiper lip is typically shaped to create a scraping action that dislodges contaminants while allowing minimal fluid escape. Additionally, the choice of material is pivotal; it must be compatible with the operating environment to prevent corrosion and wear.

Future Trends and Innovations

As industries continue to evolve, the demand for high-performance sealing solutions is increasing. Manufacturers are continuously exploring new materials and design technologies to enhance the performance of metal wiper seals. Innovations such as surface treatments and advanced composites may lead to even more robust seals that offer superior resistance to wear and environmental factors.

Moreover, the integration of IoT (Internet of Things) technologies into sealing solutions is on the rise. Smart seals capable of providing real-time data on their condition can significantly enhance maintenance strategies, enabling predictive maintenance and reducing the risk of unexpected failures.

Conclusion

In conclusion, metal wiper seals play a pivotal role in ensuring the efficiency and longevity of industrial machinery. Their ability to protect critical sealing components from contamination makes them indispensable in numerous applications. With ongoing advancements in materials and design, the future of metal wiper seals promises even greater performance and reliability, ultimately contributing to more efficient and cost-effective industrial operations. As the demand for more resilient sealing solutions grows, the importance of understanding and utilizing metal wiper seals becomes ever more critical for engineers and manufacturers alike.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories