دېكابىر . 11, 2024 12:12 Back to list

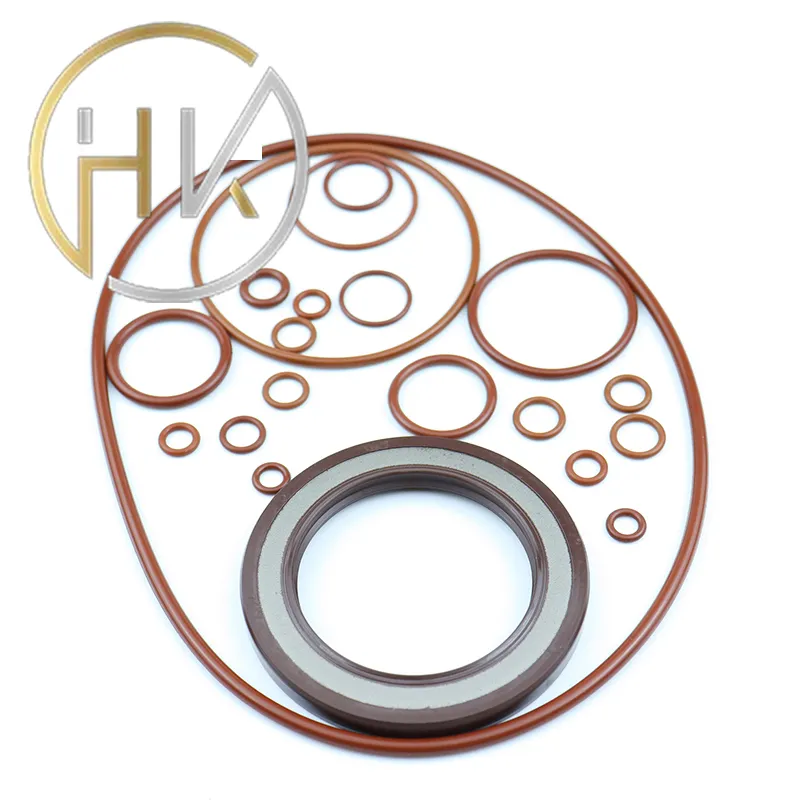

hydraulic rod wiper seal

Understanding Hydraulic Rod Wiper Seals Function, Types, and Applications

Hydraulic systems are integral to various industries, providing the power necessary for moving heavy loads, lifting equipment, and facilitating complex machinery operations. Among the many components that make up hydraulic systems, the hydraulic rod wiper seal plays a pivotal role, often overlooked in discussions about system performance and longevity. This article explores the functionality, types, and applications of hydraulic rod wiper seals, highlighting their importance in fluid power technology.

Functionality of Hydraulic Rod Wiper Seals

The primary function of a hydraulic rod wiper seal is to prevent contaminants, such as dirt, dust, and moisture, from entering the hydraulic cylinder. These seals are typically located at the exterior of the cylinder and work to wipe the rod clean as it extends and retracts. This action is critical, as the hydraulic fluid's integrity can be compromised by any dirt or debris that makes its way into the system.

Furthermore, hydraulic rod wiper seals help maintain system pressure by ensuring that hydraulic fluid does not leak out of the cylinder. They are designed to withstand harsh operating conditions, including varying temperatures, pressures, and exposure to different fluids. The longevity and performance of the hydraulic system greatly depend on the efficiency and reliability of these wiper seals.

Types of Hydraulic Rod Wiper Seals

There are several types of hydraulic rod wiper seals, each designed for specific applications and environmental conditions

. The most common types include1. Standard Wiper Seals These are the most basic form of wiper seals, designed for general-purpose applications where minimal dirt and contamination are expected. They often rely on a simple lip design to perform their function effectively.

2. Heavy-Duty Wiper Seals As the name suggests, these seals are built for more demanding conditions. They are made from tougher materials and often feature reinforced designs to withstand higher pressures and greater wear and tear.

3. U-cup Seals These seals have a U-shaped cross-section that enhances their ability to wipe the rod clean while also providing a good seal against hydraulic fluid. U-cup seals are suitable for applications where moderate levels of contamination are expected.

hydraulic rod wiper seal

4. Double Lip Wiper Seals Featuring two sealing lips, these seals provide an additional layer of protection against contaminants. They are particularly useful in environments where exposure to abrasive materials is common.

5. Custom Seals In some cases, off-the-shelf solutions may not meet specific industry requirements. Custom wiper seals can be designed to fit particular applications, accommodating unique dimensions, pressures, and environmental conditions.

Applications of Hydraulic Rod Wiper Seals

Hydraulic rod wiper seals are found in a myriad of applications across various industries. Some notable ones include

- Construction Equipment Hydraulic systems in excavators, bulldozers, and cranes rely on wiper seals to protect their cylinders from dirt and debris common on job sites.

- Automotive Industry Hydraulic lifts and systems in vehicles benefit from the use of rod wiper seals, ensuring the reliability of systems like brakes and suspension.

- Agricultural Machinery Tractors and harvesters with hydraulic systems require effective wiper seals to function optimally in dusty and wet environments.

- Marine Applications In boats and ships, hydraulic systems operate in challenging conditions. Wiper seals help ensure that the cylinders remain free from seawater and other contaminants.

Conclusion

Hydraulic rod wiper seals are indispensable components in the functionality and longevity of hydraulic systems. By preventing contaminants from entering the system and maintaining internal pressures, these seals enhance the reliability and efficiency of hydraulic applications across industries. Understanding the types and functionalities of these seals enables engineers and technicians to make informed decisions about their integration into hydraulic systems, ultimately leading to improved performance and reduced downtime. As technology continues to advance, it is likely that wiper seal designs will evolve, adapting to new challenges and ensuring that hydraulic systems remain robust and efficient in their operations.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories