نويابىر . 10, 2024 22:52 Back to list

Hydraulic Motor Seal Kit Maintenance for Optimal Performance and Longevity

Understanding Hydraulic Motor Seal Kits A Comprehensive Guide

Hydraulic systems are integral to various industrial applications, playing a crucial role in enhancing efficiency and performance. At the heart of these systems, hydraulic motors are pivotal for converting hydraulic energy into mechanical energy. However, to ensure optimal functionality and longevity, maintaining these motors is essential, and this is where hydraulic motor seal kits come into play.

What is a Hydraulic Motor Seal Kit?

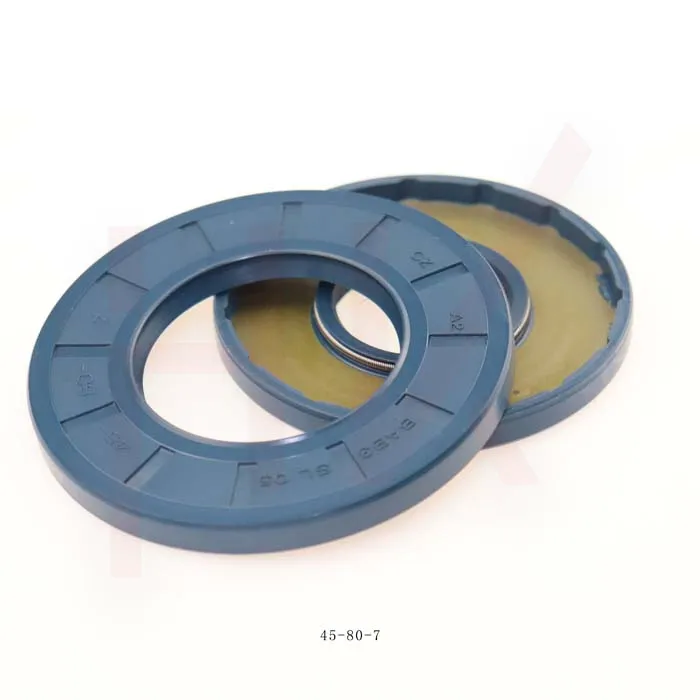

A hydraulic motor seal kit is a collection of seals and gaskets designed to prevent fluid leaks in hydraulic motors and associated components. These kits are vital for ensuring that hydraulic fluid remains contained within the system, preventing leakage that could lead to reduced efficiency, environmental hazards, and significant operational costs. The kit typically includes various O-rings, lip seals, backup rings, and sometimes additional components like wear rings, depending on the specific needs of the hydraulic motor.

Importance of Seals in Hydraulic Motors

Seals are critical in hydraulic systems as they serve multiple functions

1. Leak Prevention Seals act as barriers that prevent hydraulic fluid from leaking out of the motor, which is essential for maintaining pressure and efficiency.

2. Contamination Control Seals keep out contaminants such as dust and grit, which could degrade the hydraulic fluid and damage the motor components.

3. Pressure Retention Proper seals ensure that the system maintains the required pressure for optimal operation, which is crucial for effective machinery performance.

Types of Seals in a Hydraulic Motor Seal Kit

There are several types of seals commonly found in a hydraulic motor seal kit

- O-Rings These circular seals are made from various materials like rubber or polyurethane and are designed to fit into a groove, providing a flexible seal that can withstand pressure.

hydraulic motor seal kit

- Lip Seals Also known as radial seals, these seals have a lip that conforms to the surface of the motor shaft, creating a tight seal to prevent leaks.

- Backup Rings Used in conjunction with O-rings, backup rings prevent extrusion of the O-ring at high pressures, ensuring longevity and reliability.

- Wear Rings These components prevent metal-to-metal contact between moving parts, reducing wear and improving hydraulic efficiency.

Choosing the Right Seal Kit

When selecting a hydraulic motor seal kit, it is essential to consider several factors

1. Compatibility Ensure that the seal kit is compatible with the specific model of hydraulic motor you are using. Manufacturers often provide detailed specifications regarding which kits are suitable for their products.

2. Material Quality The material of the seals is crucial for durability. Common materials include nitrile rubber, fluorocarbon, and polyurethane. Each material offers different properties suited to various operating conditions, such as temperature and chemical exposure.

3. Operating Conditions Consider the pressure and temperature ranges of your hydraulic system. Seals must be rated for the maximum pressure and temperature they will encounter to avoid premature failure.

Maintenance and Replacement

Routine maintenance of hydraulic motors includes regular inspection and replacement of seal kits. Signs that seals may need replacement include visible leaks, lower performance, or abnormal noises during operation. Regular maintenance can mitigate costly repairs and downtime, ensuring that machinery operates smoothly and efficiently.

Conclusion

Hydraulic motor seal kits play a vital role in the operation and maintenance of hydraulic systems. By understanding the components and importance of these kits, operators can effectively manage their hydraulic systems, ensuring long-lasting performance and efficiency. Whether you are running heavy machinery or smaller equipment, investing in quality hydraulic motor seal kits is key to preventing leaks, maintaining pressure, and controlling contamination — ultimately leading to improved operational reliability and reduced costs.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories