نويابىر . 13, 2024 08:19 Back to list

hub bearing seal

Hub Bearing Seal An Essential Component for Vehicle Performance

A hub bearing seal is a critical component in a vehicle's overall performance, ensuring that the hub assembly functions efficiently while protecting it from environmental contaminants. Often overlooked, this small yet vital part plays a significant role in the longevity and reliability of a vehicle's wheel bearings.

The primary function of the hub bearing seal is to prevent dirt, moisture, and other debris from infiltrating the hub assembly. Wheel bearings are subjected to various stresses during the vehicle's operation, including load from the vehicle’s weight and the forces exerted during acceleration and braking. If external elements enter the hub, they can lead to increased wear, corrosion, and ultimately, bearing failure. Therefore, a robust hub bearing seal is essential for maintaining the integrity of the wheel hub and ensuring that the bearings operate smoothly.

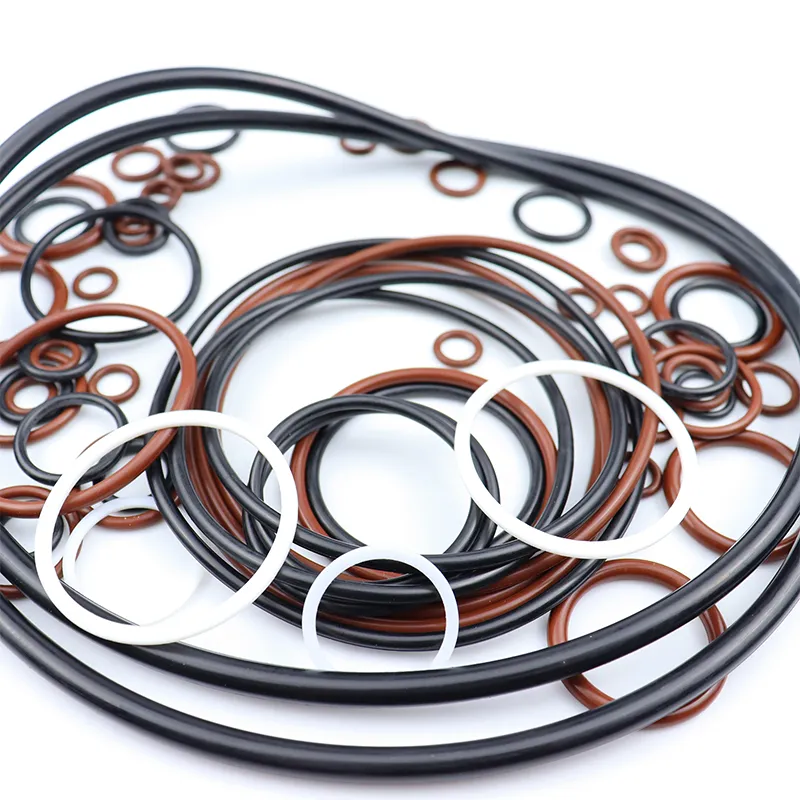

Hub bearing seals come in various designs, typically made from durable rubber or synthetic materials that can withstand high temperatures and pressures. They are engineered to provide a tight fit, preventing contaminants from entering while allowing for the necessary range of motion for the bearings. The design of the seal also includes features such as a labyrinth structure or lip design, which enhances its sealing capabilities. These innovative designs help ensure that the seal remains effective over time, even in harsh driving conditions.

hub bearing seal

Regular maintenance of hub bearing seals is crucial, especially for vehicles that operate in extreme environments, such as those exposed to mud, snow, or salt. Signs of a failing seal can include unusual noises coming from the wheel area, play in the wheel, or visual inspection revealing cracks or wear on the seal itself. Timely replacement of damaged hub bearing seals is essential to prevent more extensive and costly repairs related to bearing damage.

As technology advances, manufacturers are developing improved hub bearing seals that offer enhanced durability and performance. Some seals now feature integrated grease retention systems, which not only provide better sealing but also prolong the life of the grease within the bearing cavity. This advancement further reduces maintenance frequency and improves overall vehicle reliability.

In conclusion, the hub bearing seal may be a small component, but its impact on vehicle performance is substantial. By serving as a protective barrier against contaminants, it plays a crucial role in ensuring the longevity of the hub assembly and the vehicle’s overall functionality. Vehicle owners and maintenance professionals should prioritize the inspection and maintenance of hub bearing seals to prevent potential failures and ensure a smooth, safe driving experience. Regular checks and timely replacements can save time and money in the long run, keeping vehicles running smoothly on the road for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories