دېكابىر . 20, 2024 01:04 Back to list

high pressure lip seal

Understanding High Pressure Lip Seals Key Components in Fluid Dynamics

In the realm of mechanical engineering and fluid dynamics, seals play a critical role in ensuring the efficient operation of various systems. Among the different types of seals, high pressure lip seals are particularly noteworthy due to their ability to withstand significant pressure while preventing leakage. This article delves into the characteristics, applications, and benefits of high pressure lip seals, highlighting their importance in various industries.

What is a High Pressure Lip Seal?

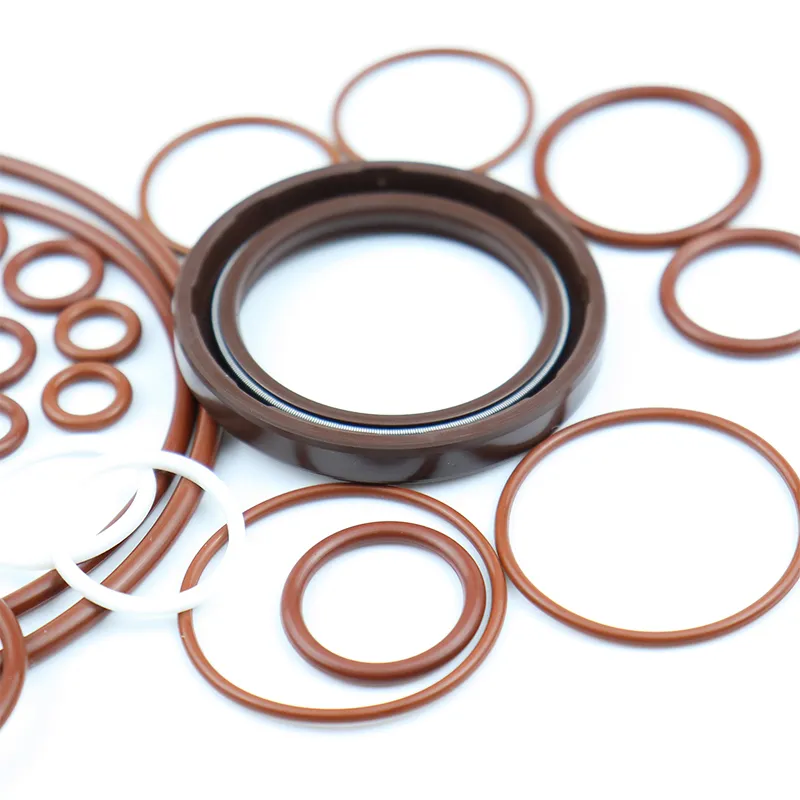

A high pressure lip seal is a type of sealing device designed to create a barrier between moving and stationary components in a system, effectively preventing the escape of fluids under high pressure conditions. These seals typically consist of a flexible rubber or elastomeric lip that makes contact with a polished surface, such as a shaft or housing. The design allows the lip to adapt to surface irregularities, enhancing its sealing capabilities.

The construction of high pressure lip seals often includes a reinforcement such as a metal or plastic casing to maintain the lip's shape and provide additional strength. This reinforcement helps the seal withstand not only high pressures but also extreme temperatures, making it suitable for a wide range of applications.

Key Characteristics

One of the foremost characteristics of high pressure lip seals is their ability to maintain effective sealing under varying conditions

. They are designed to handle pressures ranging from moderate levels up to several thousand psi. The lip's flexibility allows it to conform to the mating surface, thus reducing the chances of wear and minimizing the risk of fluid leakage.Additionally, high pressure lip seals are resilient to contamination. In many industrial applications, seals are exposed to harsh environments that include dirt, dust, and other particulates. The design of high pressure lip seals helps to block these contaminants from entering the system, ensuring longer life and reliability.

Another important feature is their versatility. High pressure lip seals can be custom-designed to accommodate different sizes, pressure requirements, and environmental conditions. This adaptability makes them suitable for a plethora of applications across various fields, including automotive, aerospace, manufacturing, and oil & gas industries.

high pressure lip seal

Applications

High pressure lip seals are employed in numerous systems where maintaining pressure integrity is vital. One prominent application is in hydraulic and pneumatic systems, where the seals prevent fluid leakage and ensure the efficient functioning of pumps and cylinders. In automotive engineering, high pressure lip seals are used in engines and transmission systems to prevent oil leaks and maintain lubrication.

In aerospace, these seals are critical components in aircraft systems, helping to ensure reliability and safety during operation. Similarly, in the oil and gas sector, high pressure lip seals are used in drilling equipment and pipeline systems, where they prevent the loss of valuable resources while withstanding extreme pressures and temperatures.

Benefits

The adoption of high pressure lip seals in various applications offers several benefits. Primarily, they enhance system efficiency by preventing fluid loss, which could lead to decreased performance and increased energy costs. Moreover, by effectively blocking contaminants, high pressure lip seals contribute to reduced maintenance requirements and prolonged equipment lifespan.

Another significant advantage is environmental protection. By preventing leaks, high pressure lip seals help minimize the risk of spills and contamination, thereby aligning with global sustainability efforts. Industries are increasingly recognizing the importance of using effective sealing solutions not only for operational efficiency but also for their commitment to environmental stewardship.

Conclusion

In summary, high pressure lip seals are indispensable components in ensuring the integrity of fluid systems across various industries. Their ability to withstand significant pressure, resist contamination, and adapt to different environments makes them a popular choice for engineers and manufacturers alike. As technology progresses and the demands on industrial systems increase, the role of high pressure lip seals will continue to expand, paving the way for more innovative and efficient solutions in fluid dynamics. Whether in aerospace, automotive, or energy applications, these seals will remain crucial in maintaining performance, safety, and environmental responsibility.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories