نويابىر . 12, 2024 03:43 Back to list

dust proof sealing

Dust Proof Sealing Ensuring Longevity and Performance

In today’s fast-paced world, dust is more than just an annoyance; it can significantly affect the functionality and lifespan of electronic devices, machinery, and various equipment. This is where the concept of dust proof sealing comes into play, offering essential protection against particles that may interfere with operations.

Dust proof sealing refers to a variety of techniques and materials used to create barriers against dust and other particulate matter. These seals are critical in applications ranging from consumer electronics, such as smartphones and laptops, to industrial machinery and automotive components. A well-designed dust seal not only enhances the product’s durability but also improves its overall performance.

The principles of dust proof sealing are rooted in understanding how dust particles behave and interact with surfaces. Dust can accumulate in intricate areas, causing overheating in electronics, leading to failures, or impairing the function of mechanical parts. Therefore, a comprehensive sealing solution is paramount. The primary goal is to prevent dust ingress, ensuring that the internal components remain clean and unobstructed.

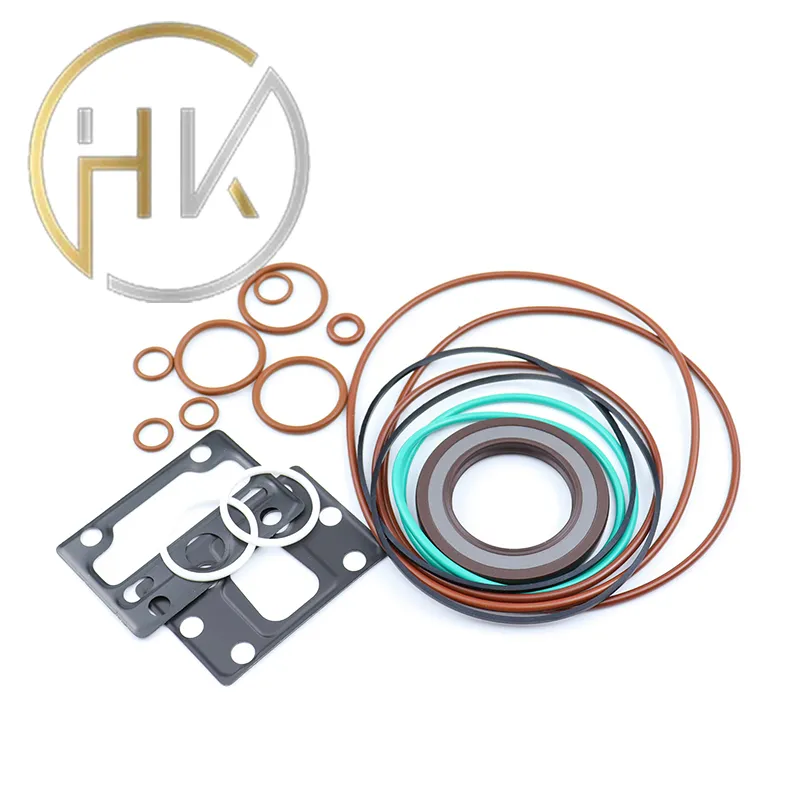

There are various materials and techniques used in creating effective dust proof seals. Gaskets, O-rings, and specialized adhesives are commonly employed to form tight seals that inhibit dust penetration. Additionally, advanced polymers and elastomers are often used due to their flexibility and durability. These materials are engineered to withstand environmental stresses such as temperature fluctuations, moisture, and exposure to chemicals, making them suitable for a range of applications.

dust proof sealing

In the consumer electronics industry, for instance, manufacturers often prioritize dust proof sealing as part of their design philosophy. Devices like smartphones and tablets are frequently exposed to environments that can cause dust accumulation. As such, many brands implement IP (Ingress Protection) ratings to certify their products' resistance to dust and water. An IP67 rating, for example, indicates that a device is dust-tight and can withstand immersion in water, providing consumers with peace of mind regarding their device's resilience.

In industrial settings, dust proof sealing is equally critical. Machinery exposed to dust and grit can suffer from wear and tear at an accelerated rate. Implementing effective sealing solutions in these environments can lead to significant cost savings by reducing maintenance needs and extending the machinery's operational lifespan. Industries such as manufacturing, agriculture, and construction rely heavily on robust dust sealing solutions to protect their investments.

Moreover, advances in technology have given rise to innovative sealing solutions. For example, 3D printing techniques are being employed to produce highly customized seals that meet specific requirements for complex shapes and sizes. This ensures that manufacturers can deliver tailored solutions that provide maximum protection against dust for varied applications.

The benefits of dust proof sealing extend beyond protection. They also contribute to energy efficiency. Equipment that operates in a dust-heavy environment often requires more energy to perform optimally if dust accumulates on critical components. By ensuring these components remain dust-free, energy consumption can be minimized, leading to lower operational costs.

In conclusion, dust proof sealing plays an essential role across various industries and applications. From safeguarding consumer electronics to ensuring the efficient operation of industrial machinery, the implementation of effective sealing solutions is crucial. As technology continues to evolve and the demand for durable products grows, the importance of dust proof sealing will undoubtedly remain a top priority for manufacturers looking to provide quality, performance, and longevity in their offerings. Investing in effective dust sealing not only protects assets but also enhances overall operational efficiency and sustainability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories