يانۋار . 20, 2025 07:24 Back to list

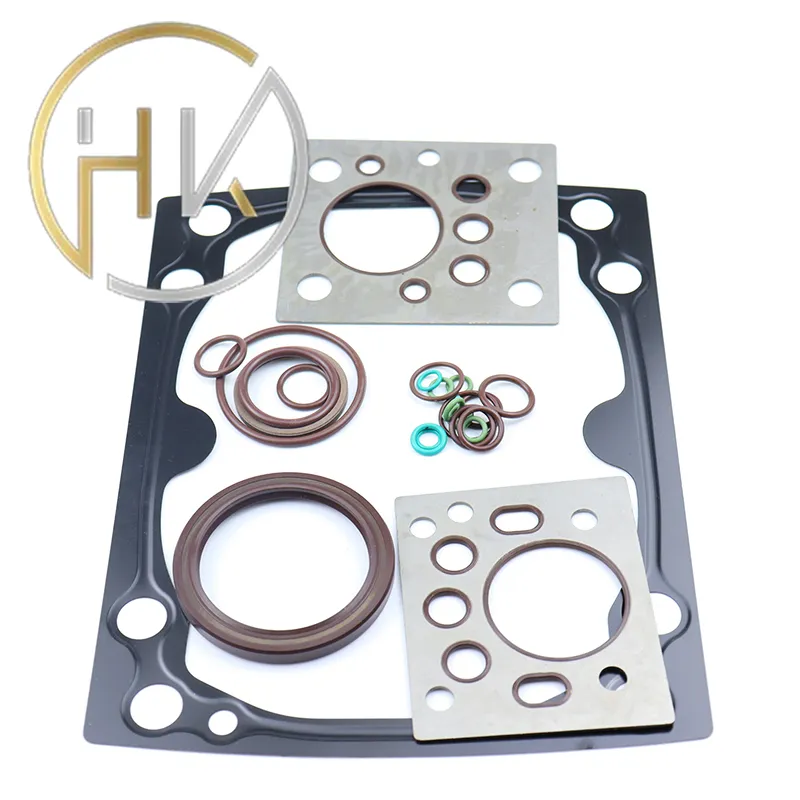

boom cylinder seal kit

Trustworthiness is also a key pillar when considering the source of your boom cylinder seal kit. It’s crucial to procure these kits from reputable suppliers or manufacturers known for their commitment to quality. Look for suppliers who offer warranties or satisfaction guarantees, which instill confidence in their products. Additionally, customer reviews and testimonials can provide valuable insights into the reliability of a supplier and the performance of their seal kits in real-world applications. A supplier with positive feedback and a robust return policy typically reflects a trustworthy business model. One cannot overlook the importance of installation when discussing boom cylinder seal kits. Even the highest quality seal kit can underperform if not installed correctly. Our expertise recommends that installation should be handled by skilled technicians familiar with hydraulic systems. Proper installation involves not only fitting the seals precisely but also ensuring that the cylinder surfaces are clean and free of any debris that could compromise seal integrity. Investing in proper installation mitigates the risk of leaks and prolongs the functional life of both the seal kit and the cylinder. In conclusion, the boom cylinder seal kit plays a pivotal role in the seamless operation of hydraulic machinery. By choosing reliability and quality, operators can enhance their equipment's performance while minimizing downtime. My expertise in this field emphasizes the importance of not only selecting the right kit but also ensuring proper installation and maintenance. By adhering to these guidelines, machinery owners can secure a tangible competitive advantage, assuring that their apparatus remains in peak operational condition, ultimately leading to substantial cost efficiency and sustained equipment productivity.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories