ئۆكتەبىر . 10, 2024 11:27 Back to list

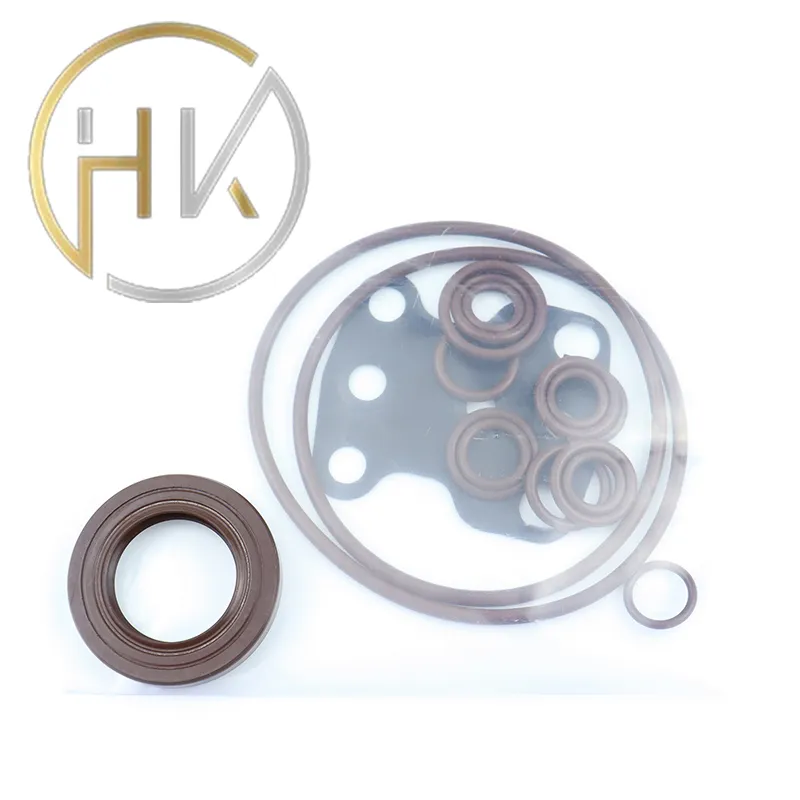

8mm Diameter Shaft Seals for Enhanced Performance and Longevity in Various Applications

Understanding 8mm Shaft Seals Importance and Applications

Shaft seals play a crucial role in various mechanical systems by preventing the leakage of fluids and contaminants from and into rotating shafts. Among the various sizes and types available, the 8mm shaft seal is particularly notable for its versatility and widespread application in many industrial and commercial settings.

The primary function of an 8mm shaft seal is to provide a barrier between the rotating shaft and the surrounding environment. By effectively sealing the gap between the shaft and the housing, these seals help maintain the integrity of the lubricants inside machinery, which in turn supports optimal performance and longevity of the equipment. They are engineered to withstand a range of pressures and temperatures, making them suitable for diverse applications.

8mm shaft seals are commonly used in automotive components, such as engines and transmissions

. In these systems, the seal ensures that oil and transmission fluid remain contained, preventing leaks that could lead to significant mechanical failures or performance issues. Furthermore, these seals are vital in agricultural machinery, consumer appliances, and HVAC systems, where they help maintain efficiency and safety.8mm shaft seal

The construction of an 8mm shaft seal typically includes materials like rubber or elastomers, which provide flexibility and durability. The design may incorporate features such as spring-loaded mechanisms that enhance sealing capabilities and accommodate any slight eccentric movements of the shaft. This adaptability is essential, as it allows the seal to perform effectively under varying operational conditions.

When selecting an 8mm shaft seal, several factors must be considered, including the type of fluid being sealed, temperature ranges, and the mechanical environment. Selecting the correct seal ensures that the machinery operates smoothly, reducing maintenance costs and downtime. Additionally, it helps in compliance with regulatory standards for fluid containment, particularly in industries handling hazardous materials.

Installation of 8mm shaft seals should be performed with care to avoid damage during the process. Proper alignment and fitting are crucial to ensure a tight seal, which is paramount for effective performance. Regular inspection and replacement of worn seals are also recommended as part of proactive maintenance strategies.

In conclusion, 8mm shaft seals are essential components in a wide range of machinery, providing vital protection against fluid leakage and contamination. Their importance cannot be overstated, as they contribute significantly to operational efficiency, safety, and the longevity of equipment across various industries. Investing in high-quality seals and adhering to proper maintenance practices can lead to substantial long-term benefits for any mechanical system.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories