Янв . 14, 2025 10:02 Back to list

pu oil seal

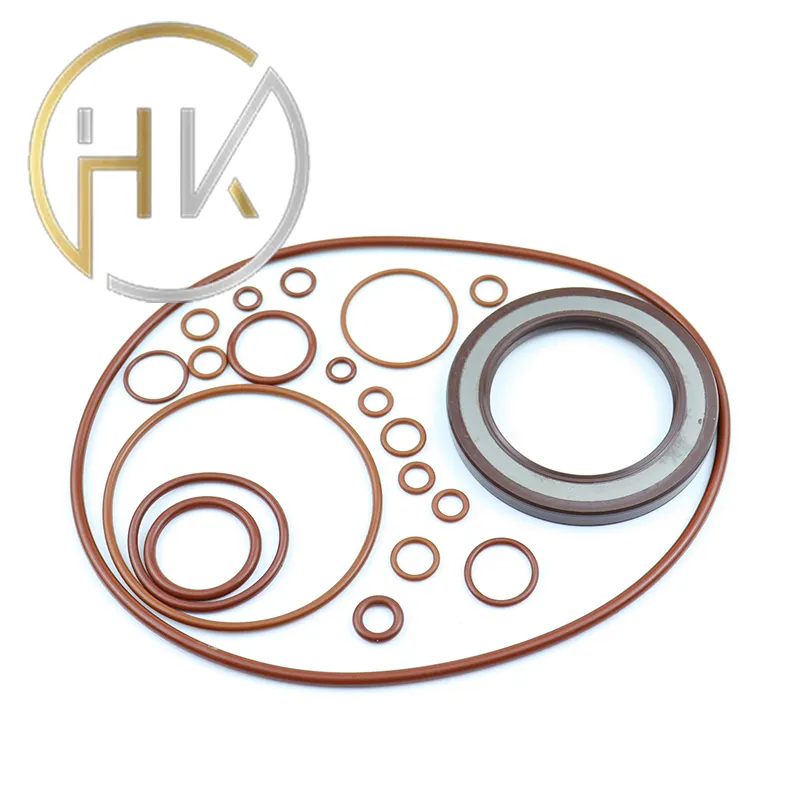

Authoritativeness in the realm of PU oil seals involves recognizing the technological advancements and innovative designs that manufacturers are offering. Industry leaders often use cutting-edge technology to produce seals that not only meet but exceed international standards. Many of these companies are ISO certified, which adds a layer of accountability and trust. As a practitioner who relies heavily on these products, I always verify certifications and manufacturer reputations before making a purchase decision. This ensures that the seals are of top-notch quality and will perform as expected under precise conditions. Trustworthiness comes from both the product’s performance and the support offered by manufacturers. A seal is only as good as it promises, and reliable manufacturers often back their products with comprehensive warranties and after-sale services. I encourage end-users to not only look at the technical specifications but also assess the level of customer service and support provided. A trustworthy supplier will offer assistance in troubleshooting and provide replacements if any defects are noticed, adhering to high standards of customer satisfaction. In conclusion, the PU oil seal is a vital component engineered for durability, efficiency, and reliability. Its development includes deep-rooted expertise, ensuring it's tailored to meet diverse operational requirements across industries. By selecting PU oil seals from authoritative and trustworthy sources, businesses can significantly enhance the performance and longevity of their machinery. Exploration into innovative sealing solutions should remain an ongoing effort to harness the full potential of these remarkable tools, driving productivity while minimizing economic losses due to equipment failures.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories