Дек . 05, 2024 10:36 Back to list

hub seals by size

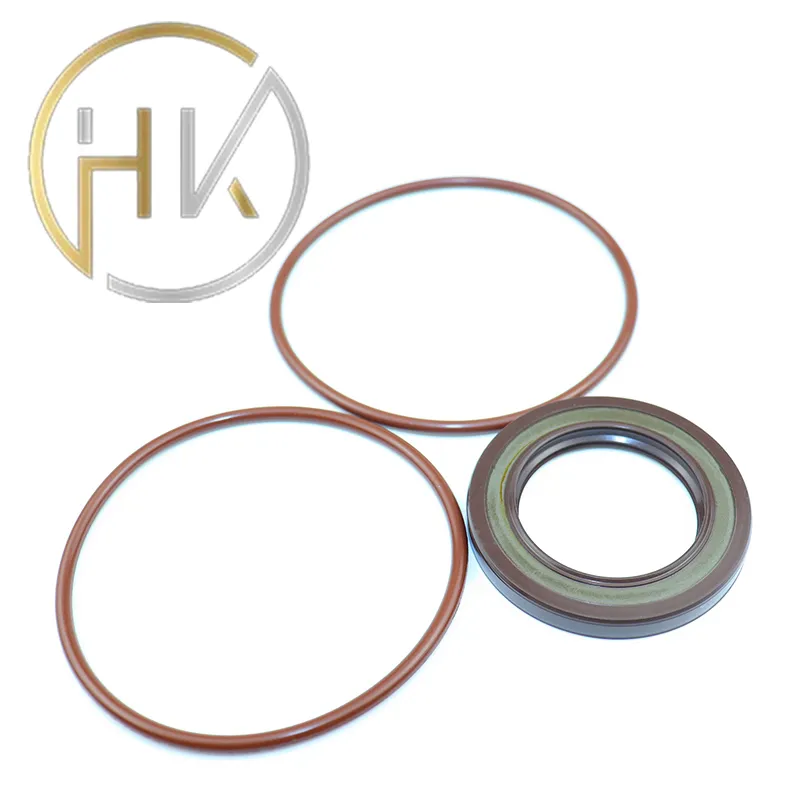

Understanding Hub Seals by Size A Comprehensive Guide

Hub seals play a crucial role in ensuring the longevity and efficiency of various types of machinery, from automobiles to industrial equipment. These small yet significant components prevent the ingress of dirt, moisture, and contaminants while retaining lubrication inside the hub assembly. Understanding hub seals, particularly by their size, is essential for anyone involved in maintenance, repair, or assembly tasks across various industries. In this article, we will explore the importance of hub seals, the factors influencing their size, and how to select the right size for your specific needs.

The Importance of Hub Seals

Hub seals are designed to provide a tight barrier between the hub assembly and the outside environment. This barrier is crucial for a few reasons

1. Protection Against Contaminants Hub seals prevent dust, dirt, and other contaminants from entering the hub, which can lead to wear and tear of the internal components. This is especially important in environments where machinery is exposed to harsh conditions.

2. Retention of Lubricants Hub seals help to retain lubricating oils or greases within the assembly, ensuring that moving parts are adequately lubricated. This minimizes friction and overheating, thereby extending the life of the components.

3. Safety By keeping contaminants out and lubricants in, hub seals play a vital role in the safety and reliability of machinery. A failure in the sealing mechanism can lead to equipment malfunction, which can have severe consequences in industrial settings.

Factors Influencing Hub Seal Size

Several factors determine the appropriate size of a hub seal, including

1. Hub Diameter The most critical dimension in selecting a hub seal is the hub diameter. Hub seals come in various diameters, and choosing the correct one ensures a snug fit, which is essential for optimal sealing performance.

2. Seal Width The width of the hub seal also plays a significant role in its effectiveness. A seal that is too wide may create unnecessary friction, while one that is too narrow may not provide adequate protection.

hub seals by size

3. Material The material of the seal can also affect its profile and size. Common materials include rubber, silicone, and polymer blends, each of which has different characteristics that can influence the seal's performance under various conditions.

4. Operating Conditions The application and operating conditions, such as temperature, pressure, and exposure to chemicals, can dictate the type and size of the hub seal needed. For example, seals used in high-temperature environments may require specific materials that can withstand heat without degrading.

Selecting the Right Hub Seal Size

To select the appropriate size of a hub seal, one must consider the following steps

1. Consult Manufacturer Specifications Always check the machinery's service manual or manufacturer specifications for recommended hub seal sizes. These documents provide critical information pertaining to the right seal dimensions.

2. Measure Existing Seals If replacing a seal, carefully measure the dimensions of the current seal, including the inner and outer diameters and width. This ensures a proper fit with the new component.

3. Consider the Application Factor in the operating environment and requirements. For instance, if the hub will be subjected to heavy loads and high speeds, ensure that the selected seal can accommodate these conditions.

4. Seek Expert Advice When in doubt, consulting with a specialist in the field can help clarify which size and type of hub seal would be the most effective for your particular application.

Conclusion

Understanding hub seals by size is vital for maintaining the efficiency and longevity of machinery across different applications. By considering factors like hub diameter, seal width, material, and operating conditions, one can make informed decisions when selecting these important components. Properly sized hub seals not only enhance machinery performance but also contribute to safety and reliability in various industrial and automotive applications. Ensuring you have the right seal for your needs will go a long way in preventing costly repairs and extending the lifespan of your equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories