Фев . 02, 2025 01:04 Back to list

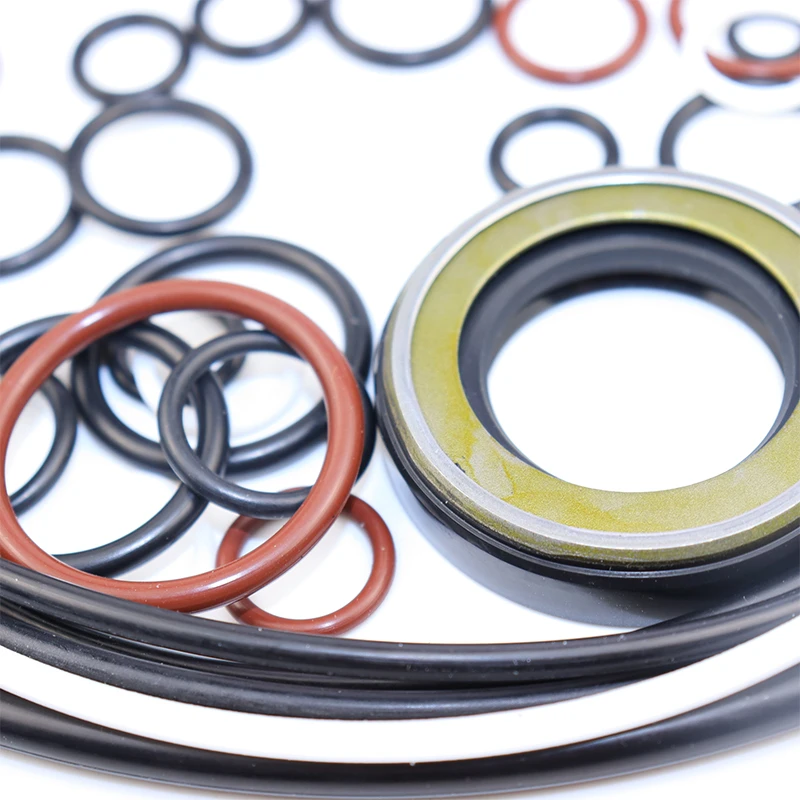

high pressure oil seals

Authoritativeness The role of high-pressure oil seals within machinery cannot be overstated. Leading industry bodies, including the Society of Tribologists and Lubrication Engineers (STLE) and the American Petroleum Institute (API), set rigorous standards for the usage and production of oil seals. These organizations' guidelines and certifications serve as benchmarks of quality and performance, ensuring that products not only meet but exceed expectations in regulated industries. Manufacturers who adhere to these standards gain a competitive edge, positioning themselves as authoritative entities within the market. Trustworthiness For businesses investing in machinery and equipment, trust in components like high-pressure oil seals is non-negotiable. This trust is built through a track record of successful field deployments, rigorous testing, and positive customer feedback. Transparency about materials, performance specifications, and testing results further bolster confidence in these products. Companies that prioritize transparency and customer support, providing clear warranties and responsive after-sales services, are seen as more trustworthy partners in the supply chain. High-pressure oil seals serve as a linchpin in a vast array of applications, from industrial compressors and hydraulic presses to automotive engines and aeronautical systems. The rigorous demands placed on these seals necessitate products that are engineered with precision and built to last. As technology advances, so too do the capabilities and applications of high-pressure oil seals, ensuring they remain an integral component in maintaining the efficiency and reliability of essential machinery worldwide.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories