Ara . 07, 2024 15:14 Back to list

water pump seal kit

Understanding Water Pump Seal Kits Essential Components for Efficient Water Pumping

Water pumps are vital to various industries, from agriculture and construction to municipal water systems and swimming pools. To ensure their efficient operation, maintaining the water pump's integrity is crucial, and this is where water pump seal kits come into play. In this article, we will explore the importance of seal kits, their components, common issues, and how to maintain them for optimal performance.

What is a Water Pump Seal Kit?

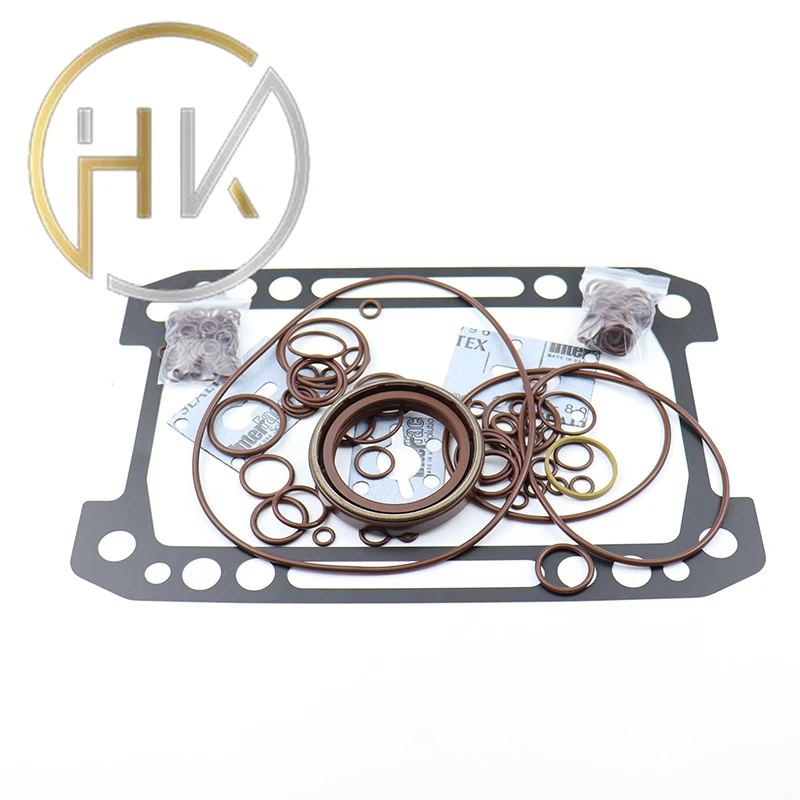

A water pump seal kit is a collection of components designed to prevent leaks and maintain the proper functioning of a water pump. These kits typically include different seals, gaskets, O-rings, and sometimes bearings, tailored specifically for the type or brand of the pump in question. Since the primary function of a seal is to separate different fluids and prevent contamination, the quality and integrity of these components are vital for pump performance.

Importance of Seal Kits

1. Preventing Leaks Water pumps commonly operate under various pressure levels, and failure to maintain proper sealing can lead to leaks. These leaks can not only reduce efficiency but can also cause environmental hazards, especially in agricultural and industrial settings where chemical contaminants may be involved.

2. Enhancing Efficiency When a pump operates with effective seals, it preserves the power supplied to it by reducing energy losses. Inefficient sealing leads to operational issues, causing the pump to work harder, which can increase energy costs significantly.

3. Extending Pump Life Regularly replacing worn-out seals with new ones from a seal kit can substantially prolong the lifespan of the pump. Ensuring that all components are in good condition minimizes wear and tear, ultimately protecting your investment.

4. Improving Performance A well-maintained water pump with new seals will perform better. It will provide a consistent flow of water without fluctuations, which is crucial for applications that depend on stable water delivery.

Common Issues Associated with Water Pump Seals

Despite their importance, seals can wear out due to several factors, including

water pump seal kit

- Temperature Fluctuations Pumps may operate in conditions of high heat or extreme cold, which can cause materials to expand or contract, leading to failure. - Chemical Exposure In applications involving certain chemicals, seals can degrade, losing their elasticity and leading to leaks.

- Physical Damage Over time, seals can be physically damaged due to vibrations, improper installation, or the presence of debris.

Maintenance Tips for Water Pump Seal Kits

1. Regular Inspection Periodically check the seals for signs of wear, such as cracks, tears, or discoloration. Early detection can prevent further damage to the pump.

2. Proper Installation When replacing seals, ensure they are installed correctly. Misalignment can lead to premature failure. Always refer to the manufacturer's instructions for correct installation procedures.

3. Maintain Cleanliness Keep the pump and surrounding area clean to avoid debris that could damage the seals. This cleanliness also aids in maintaining the overall efficiency of the pump.

4. Use Quality Replacement Parts Always choose high-quality seal kits that match the specifications of your water pump. Generic or sub-standard parts can lead to more problems down the line.

5. Monitor Performance Keep an eye on the pump's performance. Unusual noises, vibrations, or drop in pressure can signal a problem with the seals.

Conclusion

Water pump seal kits are fundamental for the efficient and reliable operation of water pumps. By understanding the importance of these kits, recognizing common issues, and implementing sound maintenance practices, users can ensure optimal performance and extend the lifespan of their water pumps. As you invest in your pumping systems, do not overlook the significance of regular maintenance and quality replacement components. Doing so will not only save money in the long run but also protect the environment and enhance operational efficiency.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories