Aug . 21, 2024 14:58 Back to list

High Performance Sealing Solutions for Extreme Pressure Applications in Industrial Settings

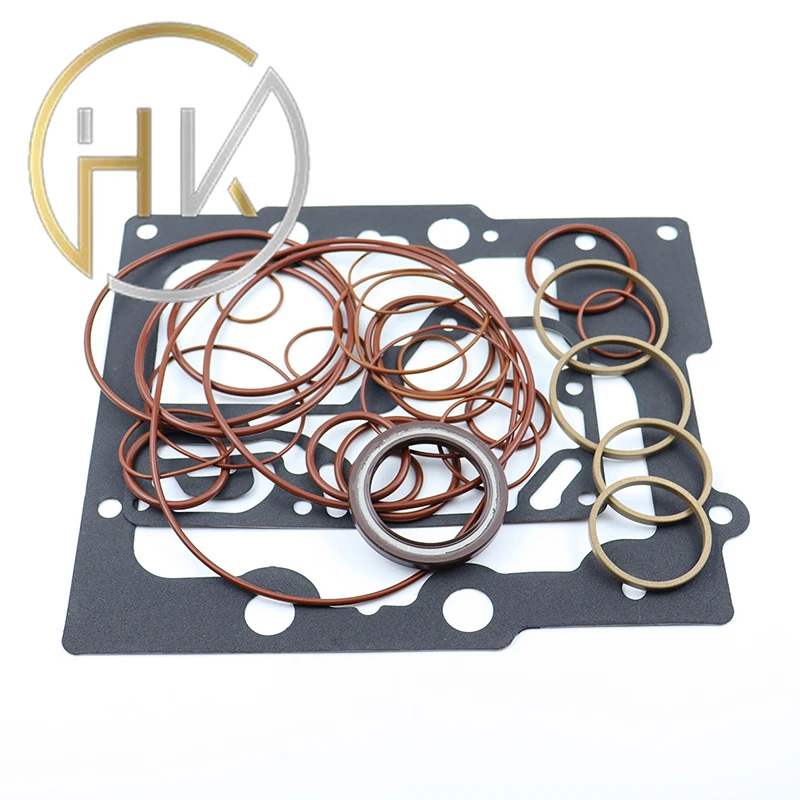

High Pressure Lip Seal An Essential Component in Industrial Applications

In the realm of mechanical engineering, the ability to effectively manage fluid movement and containment is crucial, particularly in high-pressure environments. Among the various sealing solutions available, the high pressure lip seal stands out as an efficient and reliable component used to prevent leakage in various applications.

A high pressure lip seal is designed to withstand the demands of high-pressure systems, making it ideal for industries such as oil and gas, automotive, and manufacturing. These seals are typically made from durable materials, including elastomers and polymers, which exhibit excellent resistance to wear, temperature fluctuations, and chemical exposure. The structure of a lip seal typically incorporates a flexible lip that creates a tight seal against a surface, ensuring minimal leakage and optimal performance.

One of the primary advantages of high pressure lip seals is their ability to handle substantial pressure differentials. As systems operate under high pressures, the risk of fluid leakage increases significantly. High pressure lip seals are engineered to maintain their integrity under such conditions, thus minimizing the risk of catastrophic failures that could lead to equipment damage, safety hazards, and environmental concerns. Their design allows for a balance between flexibility and strength, enabling them to adapt to varying pressure conditions while maintaining an effective seal.

In addition to their robustness, high pressure lip seals are also relatively easy to install and maintain. This ease of use translates to reduced downtime in industrial operations, as maintenance teams can quickly replace seals without extensive disassembly of machinery. This is particularly valuable in production environments where minimizing operational interruptions is a key priority. Furthermore, many high pressure lip seals are designed to be self-lubricating, which further enhances their lifespan and performance.

high pressure lip seal

The selection of the appropriate high pressure lip seal is crucial to ensuring optimal functionality. Factors such as the seal's material, dimensions, and design characteristics must be carefully considered to match the specific application requirements. For instance, in applications involving aggressive chemicals, seals made from fluoropolymer materials may be preferred due to their superior chemical resistance. Similarly, the temperature range in which the seal will operate requires careful attention, as extreme temperatures can compromise seal integrity.

Moreover, advancements in manufacturing technologies have led to the development of high-performance lip seals that incorporate innovative features. Techniques such as 3D printing and advanced polymer formulations allow for the production of bespoke seals tailored to meet the exact specifications of modern machinery. This customization capability not only enhances performance but also contributes to sustainability efforts by reducing material waste.

As industries continue to evolve, the demand for effective sealing solutions in high-pressure environments will only grow. High pressure lip seals will play an integral role in the performance and reliability of machinery across various sectors. By investing in quality seals, businesses can not only enhance their operational efficiency but also ensure compliance with regulatory standards regarding safety and environmental impact.

In conclusion, high pressure lip seals are vital components that enhance the performance and reliability of systems operating under significant pressure. Their robust design, ease of maintenance, and adaptability to various fluid conditions make them indispensable in multiple industrial applications. As technology progresses, we can expect continued improvements in seal performance and design, ensuring that these crucial components meet the ever-increasing demands of modern engineering.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories