Nov . 20, 2024 11:15 Sanawa dolan

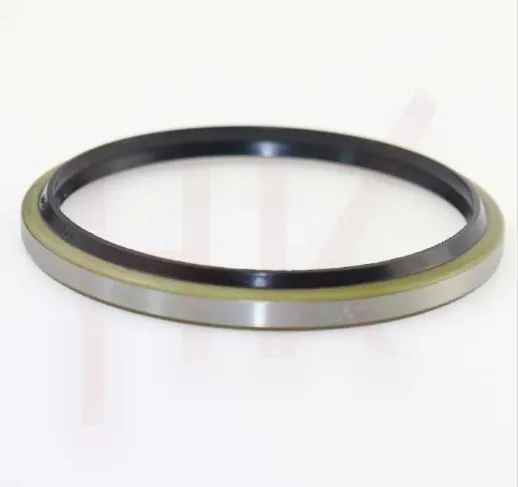

Machinery Performance with Wiper Oil Seals and Wiper Seals

When it comes to protecting hydraulic systems and mechanical equipment, wiper oil seals and wiper seals are indispensable. These seals serve as the first line of defense against contaminants such as dust, dirt, and moisture, ensuring the longevity and efficiency of machinery. In this guide, we’ll discuss the importance of these seals, how they function, and why selecting the right wiper seal is crucial for optimizing equipment performance.

The Function of a Wiper Oil Seal in Hydraulic Systems

A wiper oil seal plays a critical role in preventing external contaminants from entering the hydraulic system. Positioned on the cylinder rod, the wiper oil seal removes dirt, mud, and dust from the surface as the rod retracts into the cylinder. This ensures that no debris enters the system and compromises the internal components, such as seals and bearings, which are essential for smooth operation.

Without an effective wiper oil seal, contaminants can cause significant damage to the hydraulic system, leading to premature wear and potential failure. Therefore, the use of high-quality wiper oil seals is necessary to maintain proper functioning and reduce costly repairs.

Why Wiper Seals Are Crucial for Equipment Protection

Wiper seals are vital for protecting mechanical equipment from environmental hazards. These seals are typically used in hydraulic cylinders, keeping contaminants at bay by scraping off particles that accumulate on the piston rod during operation. In heavy-duty industries like construction, mining, and manufacturing, machinery is often exposed to dust, mud, and water. Wiper seals help ensure that the moving parts inside the hydraulic system remain clean and free from debris.

Selecting the right wiper seal is crucial for extending the lifespan of your machinery. A good wiper seal not only prevents contamination but also minimizes friction, which improves overall equipment performance and efficiency.

How Wiper Seals Enhance Performance and Longevity

A well-designed wiper seal significantly enhances the performance of hydraulic equipment by keeping contaminants out and maintaining lubrication within the system. By preventing dirt and debris from entering the hydraulic cylinder, wiper seals help reduce wear on sensitive components, such as seals and bearings, which are critical for proper machine function. This, in turn, leads to smoother operation, less downtime, and extended service intervals.

Regular inspection of wiper seals is necessary to ensure they are functioning correctly. Signs of wear, such as cracking or hardening, can reduce their effectiveness, allowing contaminants to enter the system. Replacing worn-out wiper seals promptly can prevent significant damage and help maintain optimal performance.

Choosing the Right Wiper Oil Seal for Your Application

Selecting the right wiper oil seal for your application is essential for protecting your machinery. Different materials and designs offer varying levels of protection, depending on the operating environment. For example, polyurethane wiper oil seals are ideal for heavy-duty applications due to their resistance to abrasion and harsh conditions. On the other hand, rubber wiper oil seals offer flexibility and are suitable for general-purpose machinery.

When choosing a wiper oil seal, consider factors such as temperature, pressure, and exposure to contaminants. A well-suited wiper oil seal will ensure maximum protection and reduce the likelihood of system failures due to contamination.

Maintenance Tips for Ensuring the Longevity of Wiper Seals

To ensure that wiper seals and wiper oil seals continue to provide effective protection, regular maintenance is essential. Periodic inspections should be conducted to check for signs of wear or damage, such as cracking, hardening, or deformation. Replacing worn wiper seals as soon as they show signs of deterioration can prevent contaminants from entering the system and causing more extensive damage.

In addition, keeping the area around the wiper seal clean and free of excessive dirt or debris will help prolong the seal’s lifespan. Proper lubrication is also key to maintaining the integrity of the wiper oil seal, ensuring that friction is minimized and the hydraulic system operates smoothly.

In conclusion, wiper oil seals and wiper seals are essential components for protecting hydraulic systems and machinery from contaminants. By keeping dirt, dust, and moisture out, these seals enhance equipment performance, reduce maintenance costs, and extend the lifespan of vital components. Regular maintenance and the selection of high-quality seals are critical to ensuring your machinery operates at peak efficiency, providing long-term reliability and safety.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

HabarlarJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

HabarlarJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

HabarlarJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

HabarlarJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

HabarlarJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

HabarlarJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

HabarlarJun.06,2025

Önüm kategoriýalary