Nov . 30, 2024 20:38 Back to list

hydraulic oil seal manufacturers

Hydraulic Oil Seal Manufacturers Key Players in Fluid Power Systems

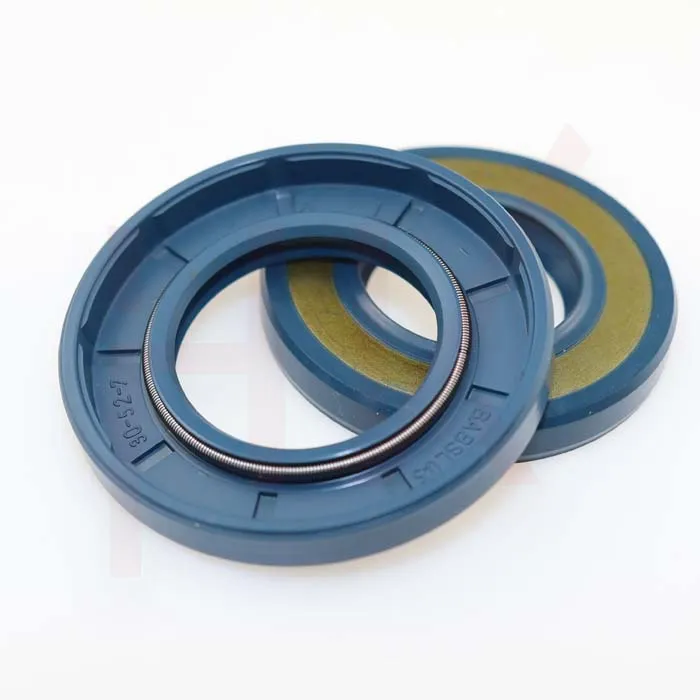

Hydraulic oil seals play a crucial role in the efficiency and longevity of hydraulic systems. These seals are designed to prevent the leakage of oil and reduce contamination from external particles. Manufacturers of hydraulic oil seals provide essential components that ensure hydraulic equipment operates smoothly and effectively. In this article, we will explore the significance of hydraulic oil seals, the manufacturing process, and some leading manufacturers in this industry.

The Importance of Hydraulic Oil Seals

Hydraulic systems are widely used across various industries, including construction, manufacturing, automotive, and aerospace. These systems rely on pressurized hydraulic fluid to transmit power. However, without high-quality oil seals, the integrity of these systems can be compromised. Oil seals help maintain pressure within the hydraulic system, prevent fluid leakage, and keep contaminants out. This, in turn, protects internal components from wear and tear, which is vital for the overall performance and reliability of the equipment.

In addition to preventing leaks, hydraulic oil seals also assist in reducing noise and vibration levels, contributing to a more efficient and quieter operation. The right seal can significantly impact the overall efficiency of the hydraulic system, which is why working with reputable manufacturers is crucial.

The Manufacturing Process

The production of hydraulic oil seals involves several key steps. Manufacturers typically use materials such as rubber, polyurethane, or silicone, known for their durability and resistance to various chemicals and temperature fluctuations. The manufacturing process typically includes the following stages

1. Material Selection Choosing the right material is the first step. Depending on the application, manufacturers must consider factors such as temperature, pressure, and the type of hydraulic fluid.

2. Molding The chosen material is molded into specific shapes and sizes. This can be done through various techniques, including compression molding, injection molding, or extrusion.

3. Curing After molding, the seals undergo a curing process, often involving heat and pressure. This step solidifies the material, enhancing its strength and elasticity.

4. Quality Control Rigorous testing is conducted to ensure the seals meet industry standards. This may include tests for dimensional accuracy, hardness, and resistance to wear.

hydraulic oil seal manufacturers

5. Packaging and Distribution Once approved, the seals are packaged for distribution. Manufacturers often offer custom solutions to meet the unique needs of their clients.

Leading Manufacturers

Several well-established manufacturers around the globe specialize in hydraulic oil seals. Here are a few notable companies in this industry

1. Parker Hannifin Parker is a leading name in the fluid power industry, offering a comprehensive range of hydraulic seals. Their commitment to quality and innovation ensures that customers receive reliable products for their hydraulic systems.

2. SKF Known for its extensive expertise in sealing solutions, SKF manufactures hydraulic seals using advanced technology and materials. Their products cater to a diverse range of applications, ensuring optimal performance and longevity.

3. Trelleborg This Swedish company is renowned for its innovative sealing technology. Trelleborg offers a wide variety of hydraulic seals, focusing on improving performance and environmental sustainability.

4. Sealol Based in India, Sealol has earned a reputation for producing high-quality hydraulic seals at competitive prices. Their extensive experience in the industry allows them to cater to various sectors, providing tailored solutions.

5. Michell Bearings Specializing in custom-engineered sealing solutions, Michell Bearings works closely with clients to develop seals that meet specific operational requirements, ensuring optimal performance in hydraulic applications.

Conclusion

Hydraulic oil seal manufacturers play a vital role in ensuring the efficiency and reliability of hydraulic systems across multiple industries. With a focus on quality materials, advanced manufacturing processes, and rigorous testing, these manufacturers provide essential components that help prevent leaks, protect systems from contamination, and extend the life of hydraulic equipment. As industries continue to evolve, the demand for innovative sealing solutions will only grow, making these manufacturers key players in the fluid power industry. Whether for construction machinery, automotive applications, or aerospace technologies, investing in high-quality hydraulic oil seals is crucial for sustained operational success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories