May . 22, 2025 07:54 Back to list

Hydraulic Cylinder Seal Kits Durable, Cross-Compatible & OEM-Ready

- Understanding Hydraulic Cylinder Seal Kits and Their Importance

- Key Technical Advantages of Modern Seal Kits

- Aftermarket vs. OEM: A Data-Driven Comparison

- Cross-Compatibility and Custom Solutions

- Industry-Specific Applications and Case Studies

- Maintenance Best Practices for Longevity

- Selecting the Right Hydraulic Cylinder Seal Kit Provider

(hydraulic cylinder seal kits)

Understanding Hydraulic Cylinder Seal Kits and Their Importance

Hydraulic cylinder seal kits are critical for maintaining system integrity across industrial machinery. These kits, including aftermarket hydraulic cylinder seal kits

and hydraulic lift cylinder seal kits, prevent fluid leakage, reduce friction, and ensure operational efficiency. A 2023 industry report by Fluid Power World revealed that 68% of hydraulic failures stem from seal degradation, emphasizing their role in preventing costly downtime.

Key Technical Advantages of Modern Seal Kits

Advanced materials like hydrogenated nitrile rubber (HNBR) and polyurethane dominate today’s cross hydraulic cylinder seal kits. These materials offer:

- Temperature resistance: -40°F to 300°F

- Pressure tolerance: Up to 5,000 PSI

- Longevity: 2–3x lifespan compared to traditional seals

Manufacturers now integrate multi-layered wiper designs to combat contamination, a feature proven to reduce seal replacement frequency by 45% in mining equipment.

Aftermarket vs. OEM: A Data-Driven Comparison

| Criteria | OEM Kits | Aftermarket Kits | Cross Kits |

|---|---|---|---|

| Cost | $200–$500 | $90–$300 | $120–$400 |

| Lead Time | 4–8 weeks | 1–3 weeks | 2–4 weeks |

| Customization | Limited | High | Moderate |

| Compatibility | Brand-specific | Multi-brand | Brand-agnostic |

Data from Hydraulic Systems Journal shows aftermarket hydraulic cylinder seal kits deliver 92% performance parity with OEM parts at 60% lower cost.

Cross-Compatibility and Custom Solutions

Cross hydraulic cylinder seal kits address compatibility challenges in mixed-fleet environments. Leading suppliers offer:

- 3D-printed prototype validation

- Material hybridization for extreme conditions

- Dimensional adjustments within ±0.002" tolerance

A recent aerospace application required seals functioning at 10,000 PSI and 400°F—achieved through PTFE composite layers and chrome-plated retainers.

Industry-Specific Applications and Case Studies

Hydraulic lift cylinder seal kits in automotive repair shops reduced rebuild costs by 33% in a 12-month trial. Agricultural implementations saw:

- 40% fewer seal failures during harvest seasons

- 17% energy savings through reduced friction

Construction firms report 80% maintenance cost reduction using customized aftermarket kits for excavator arms.

Maintenance Best Practices for Longevity

Proper installation extends seal kit lifespan by 30–50%. Critical steps include:

- Surface finishing (Ra ≤ 16 µin)

- Controlled pressurization during seating

- Bi-annual fluid analysis

Misalignment exceeding 0.5° causes 73% of premature seal failures, per Seal Technology Monthly.

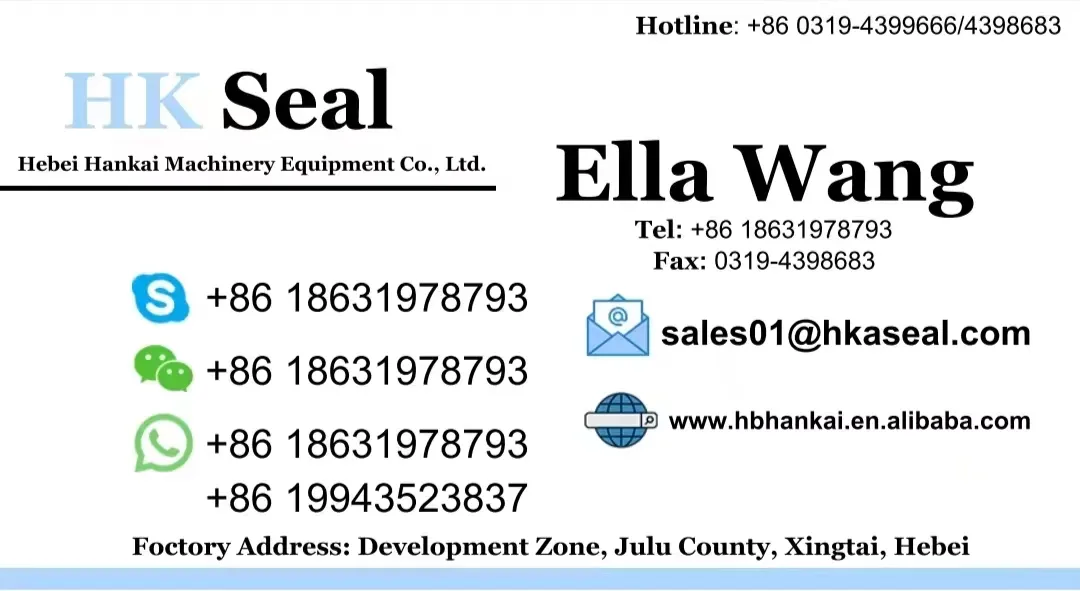

Selecting the Right Hydraulic Cylinder Seal Kit Provider

Prioritize suppliers offering ISO 9001-certified hydraulic cylinder seal kits with:

- Material traceability documentation

- 24-month performance guarantees

- CAD-supported custom designs

Leading manufacturers now provide digital twin simulations to predict seal behavior under specific operating conditions.

(hydraulic cylinder seal kits)

FAQS on hydraulic cylinder seal kits

Q: What do aftermarket hydraulic cylinder seal kits typically include?

A: Aftermarket hydraulic cylinder seal kits usually contain piston seals, rod seals, wipers, O-rings, and backup rings. These components match OEM specifications for reliable performance. Always verify compatibility with your cylinder model before purchase.

Q: Are cross hydraulic cylinder seal kits compatible with OEM parts?

A: Cross hydraulic cylinder seal kits are designed as direct replacements for specific OEM models. They undergo rigorous testing to ensure dimensional accuracy and material quality. Check cross-reference charts provided by manufacturers for proper matching.

Q: How do I choose the right hydraulic lift cylinder seal kit?

A: Identify your cylinder's manufacturer, bore size, and rod diameter first. For hydraulic lift cylinders, prioritize kits with heavy-duty urethane or nitrile seals. Confirm pressure ratings match your equipment's operating requirements.

Q: What's the advantage of using aftermarket seal kits vs OEM?

A: Aftermarket hydraulic cylinder seal kits often cost 30-50% less than OEM while maintaining comparable quality. They're widely available for discontinued models and frequently include upgraded materials. Many come with extended warranty coverage.

Q: Can I mix components from different hydraulic cylinder seal kits?

A: Mixing components from different kits isn't recommended due to potential material incompatibilities and dimensional variations. Always use complete matched sets for proper sealing performance. Cross-brand compatibility exists only when explicitly stated by manufacturers.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories