Nov . 13, 2024 18:36 Back to list

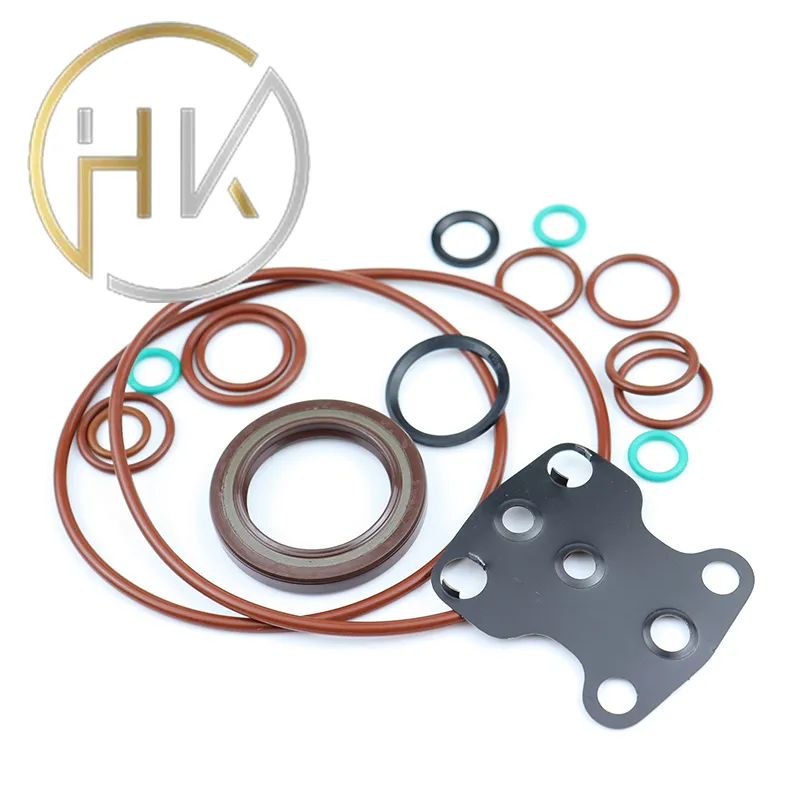

high speed rotary shaft seals

High-Speed Rotary Shaft Seals Essential Components for Machinery Efficiency

Rotary shaft seals are critical components in many machines and industrial applications, particularly in high-speed environments. These seals are designed to prevent the leakage of lubricants and other fluids while simultaneously keeping contaminants out, ensuring the smooth operation of rotating shafts. As machinery speeds increase, the importance of high-speed rotary shaft seals becomes even more pronounced. In this article, we will explore the features, materials, applications, and benefits of high-speed rotary shaft seals.

Understanding Rotary Shaft Seals

Rotary shaft seals, often referred to as lip seals or oil seals, consist of a flexible lip that makes contact with the rotating shaft. This design allows for minimal friction while providing a tight seal to prevent the loss of lubricants and entry of dirt or debris. The effectiveness of these seals is critical in applications like automotive engines, pumps, motors, and various industrial equipment.

Design and Features

High-speed rotary shaft seals are specifically engineered to withstand the challenges presented by high rotational speeds. Key features include

1. Material Selection The materials used in manufacturing high-speed seals are crucial for their performance. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and silicone, each offering different advantages in terms of temperature resistance, chemical compatibility, and durability. Advanced composite materials may also be utilized to enhance performance under extreme conditions.

2. Lip Profile Design The design of the sealing lip is tailored to minimize wear and reduce heat generation. This is particularly important at high speeds, where excessive friction can lead to seal failure. Manufacturers often employ innovative designs, such as multiple lips or varying lip profiles, to optimize sealing effectiveness and extend service life.

3. Housing and Installation Proper installation and housing design are essential for the longevity of rotary shaft seals. A well-designed housing can decrease the risk of misalignment and uneven wear, ensuring that the seal operates efficiently.

Applications

high speed rotary shaft seals

High-speed rotary shaft seals find applications across various industries, including

- Automotive They are used in engines, transmissions, and differentials to maintain lubricant integrity and protect internal components from contaminants. - Aerospace In aircraft systems where reliability and performance are paramount, these seals help maintain operational efficiency and safety. - Industrial Equipment Machinery in manufacturing plants, such as motors and pumps, often employs rotary shaft seals to ensure smooth operation and minimal downtime. - Renewable Energy Wind turbines and other renewable energy systems incorporate high-speed rotary seals to withstand environmental conditions and maintain energy efficiency.

Benefits

The benefits of using high-speed rotary shaft seals are substantial

1. Increased Efficiency By effectively sealing lubricants and preventing leaks, these seals help maintain the efficiency of machinery, resulting in better performance and reduced energy consumption.

2. Extended Equipment Life Proper sealing prevents contamination and reduces wear on critical components, which can lead to longer operational life and lower maintenance costs.

3. Reduced Downtime High-speed rotary shaft seals contribute to machine reliability. By minimizing leaks and protecting against contaminants, they help ensure that equipment runs smoothly without unexpected failures.

4. Versatile Applications The adaptability of these seals to various conditions and industries makes them essential in modern engineering practices.

Conclusion

High-speed rotary shaft seals play a vital role in the advancement of technology and machinery across multiple sectors. With their specific design features and materials engineered for performance, these seals are indispensable for ensuring operational efficiency, equipment longevity, and reduced maintenance costs. As industries continue to innovate and push the boundaries of speed and performance, the demand for reliable high-speed rotary shaft seals will only grow. Ultimately, investing in high-quality seals is not just about preventing leaks; it’s about fostering a culture of reliability and efficiency in an increasingly fast-paced world.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories