Nov . 06, 2024 09:27 Back to list

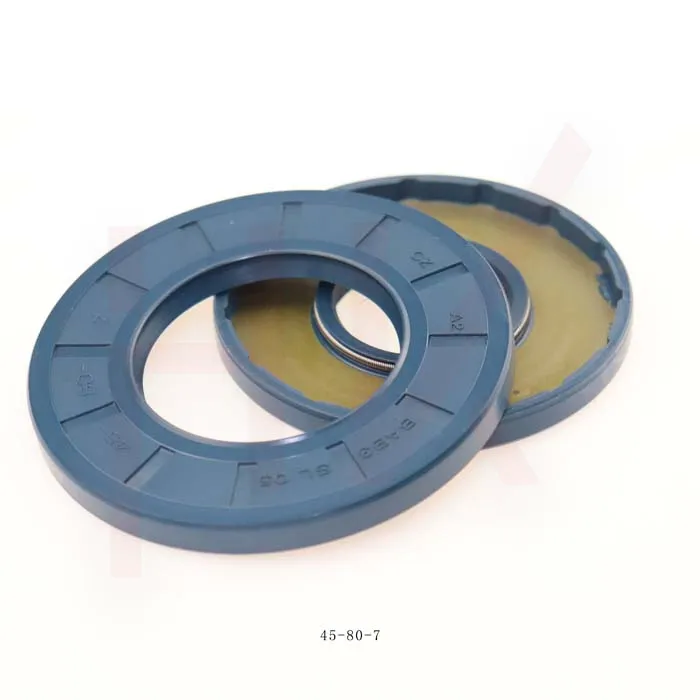

70 90 10 oil seal

Understanding Oil Seals The 70/90/10 Approach

Oil seals play a critical role in various mechanical systems by preventing the leakage of lubricants and contaminants, thus ensuring optimal performance and longevity of machinery. In this article, we'll explore the concept of oil seals through the lens of the 70/90/10 approach, applying these percentages to different aspects of oil seal design, functionality, and usage.

70% Design and Material Selection

The design and material selection of an oil seal account for around 70% of its effectiveness in preventing leaks. High-quality oil seals are meticulously engineered with precision to ensure a perfect fit in the designated applications. The materials used, such as rubber, silicone, and polyurethane, significantly influence the performance of the seal. For instance, fluoroelastomer seals are highly resistant to extreme temperatures and aggressive chemicals, making them ideal for high-performance applications, while nitrile rubber may be suitable for general-purpose use. Correct design not only contributes to leak prevention but also impacts the seal's durability and resistance to wear.

90% Installation and Maintenance

Installation and maintenance comprise approximately 90% of the factors that affect the operational efficiency of oil seals. Even the best-designed seal can fail if improperly installed. Factors such as surface finish, alignment, and cleanliness during the installation process are paramount. A dirty or rough installation surface can lead to premature wear, while poor alignment may cause uneven pressure distribution, increasing the risk of leakage.

70 90 10 oil seal

Regular maintenance is equally critical. Components of machinery should be routinely inspected for wear and tear, and seals need to be checked for signs of failure. Incorporating lubrication during installations can also minimize friction and prolong seal life, ensuring that the system operates smoothly for an extended period.

10% Testing and Quality Assurance

The final 10% focuses on testing and quality assurance, which are essential for verifying the integrity and reliability of oil seals. Manufacturers implement various testing methods to evaluate the performance of their products under different conditions. This includes pressure testing, thermal cycling, and wear testing to ensure that the seals can withstand the environments they will be exposed to.

Quality assurance processes help to identify any defects before the seals reach the market, significantly reducing the chances of seal failure during their operational lifespan.

In conclusion, the 70/90/10 approach offers a comprehensive framework for understanding oil seals. By prioritizing effective design, ensuring proper installation and maintenance, and implementing robust testing protocols, industries can significantly enhance the performance of their machinery and extend the lifespan of their oil seals. Ultimately, a well-maintained oil seal system is vital for the smooth operation of any mechanical apparatus, underscoring the importance of attention to detail in every stage of the seal's lifecycle.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories