Dec . 03, 2024 17:42 Back to list

30x52x7 Seal Specifications for Enhanced Performance and Durability Options

The 30x52x7 seal, commonly referred to in industrial applications, is a vital component in ensuring the efficient operation of machinery and equipment. Seals play an essential role in preventing leaks, maintaining pressure, and protecting components from dust, dirt, and other contaminants. This article will delve into the specifics of the 30x52x7 seal, its applications, material considerations, and importance in various industries.

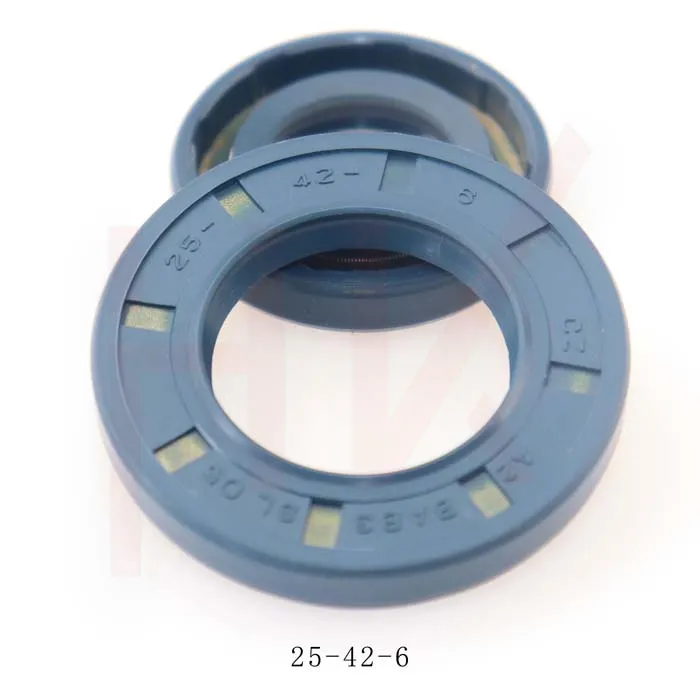

Dimensions and Specifications

The nomenclature 30x52x7 refers to the dimensions of the seal. This means that the seal has an outer diameter of 52 mm, an inner diameter of 30 mm, and a width of 7 mm. These specific measurements cater to a range of applications, particularly in rotating machinery where space constraints and precision are crucial. The dimensions ensure a snug fit, reducing the likelihood of leakage and increasing the longevity of the machinery in which they are installed.

Applications of the 30x52x7 Seal

The 30x52x7 seal is prevalent in several industries, including automotive, aerospace, and manufacturing. In automotive applications, these seals are commonly used in engines, transmissions, and differential assemblies. Their role in these applications is to maintain lubricants within the system while preventing contaminants from entering, thereby enhancing performance and extending the lifespan of engine components.

In the aerospace industry, seals like the 30x52x7 are critical for maintaining the integrity of various systems under extreme operating conditions. They prevent the ingress of moisture and debris, which can lead to malfunctions or failures in sensitive equipment. The versatility of these seals makes them suitable for hydraulic systems, landing gear, and fuel systems in aircraft.

Manufacturing machinery, particularly those involving rotating shafts and bearings, also benefit significantly from the installation of the 30x52x7 seal

. These seals protect the internal mechanisms from damage due to dust and other particulate matter while ensuring that lubricants remain contained. This is particularly critical in high-speed machinery where the presence of contaminants can lead to increased wear and tear.30x52x7 seal

Material Considerations

The material of the 30x52x7 seal is another crucial factor that influences its performance and durability. Seals are typically made from various materials, including rubber, silicone, or polyurethane, depending on the application requirements. For example, nitrile rubber is commonly used for seals in automotive applications due to its excellent resistance to oil and fuel. In contrast, silicone may be chosen for high-temperature applications due to its ability to withstand heat without degrading.

Additionally, the choice of material can also impact the seal's flexibility, compression set, and resistance to wear. In high-speed applications, seals must not only be robust but also able to deform slightly under pressure to ensure a tight fit. This ensures that they maintain effectiveness over time, reducing the frequency of replacements and maintenance required.

Importance in Various Industries

The significance of the 30x52x7 seal transcends its mere functionality. In innovative industries where technological advancements are paramount, the reliability of components—including seals—plays a critical role in the overall performance of machinery. Poorly functioning seals can lead to equipment downtime, increased operational costs, and safety hazards.

In conclusion, the 30x52x7 seal is a small but mighty component that serves multiple essential functions in various industrial applications. Its ability to prevent leaks, protect against contaminants, and maintain system integrity makes it indispensable in the automotive, aerospace, and manufacturing sectors. As industries continue to evolve, the demand for reliable sealing solutions like the 30x52x7 will undoubtedly remain vital. Investing in high-quality seals not only enhances operational efficiency but also contributes to the sustainability of machinery and equipment, underscoring the importance of high-performance seals in the modern industrial landscape.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories