ธ.ค. . 15, 2024 01:23 Back to list

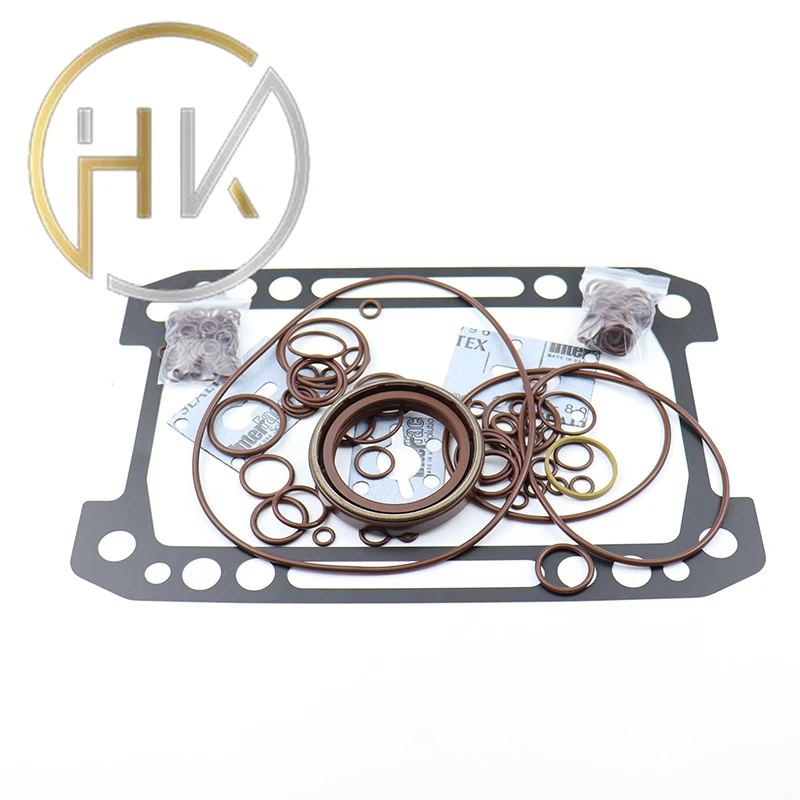

Shaft Seals and Wipers for Enhanced Equipment Performance and Longevity

Understanding Shaft Wipers Essential Components for Machinery Efficiency

Shaft wipers play a crucial role in the functionality and longevity of various mechanical systems. These components are specifically designed to prevent contaminants from entering the space between the shaft and the housing, thus ensuring smooth operation and enhancing the durability of the machinery. In this article, we will delve into the significance of shaft wipers, their construction, types, application areas, and maintenance tips to maximize their effectiveness.

The Importance of Shaft Wipers

In any machinery that uses rotating shafts, maintaining a clean operational environment is vital. Contaminants such as dust, dirt, and lubricants can lead to wear and tear, ultimately resulting in machinery failure. This is where shaft wipers come into play. They act as a barrier against external contaminants, preserving the internal components and reducing the risk of damage. By doing so, shaft wipers help maintain optimal performance, reduce the frequency of maintenance, and prolong the life of the equipment.

Construction of Shaft Wipers

Shaft wipers are typically made from durable materials such as rubber, polyurethane, or other synthetic materials that can withstand various operating conditions. Their design usually incorporates a sealing element that conforms to the shaft, ensuring a snug fit that effectively retains lubricants and blocks foreign particles. The material choice and design can vary depending on the application, as different environments may require different levels of abrasion resistance, temperature tolerance, and chemical stability.

Types of Shaft Wipers

There are several types of shaft wipers, each suited for specific applications

1. Static Wipers These are mounted in a stationary position, serving to clean the shaft as it rotates. They are generally used in applications with low-speed rotation and minimal exposure to external contaminants.

2. Dynamic Wipers Unlike static wipers, dynamic wipers adapt to the movement of the shaft. They are often used in high-speed applications where the shaft undergoes significant movement and oscillation.

3. Rotary Wipers These wipers rotate in conjunction with the shaft, actively removing contaminants. They are particularly effective in high-speed and high-load environments.

4. Magnetic Wipers These innovative wipers utilize magnetic forces to repel metal shavings and other ferrous contaminants. They are commonly found in precision machinery and automotive applications.

shaft wipers

Applications of Shaft Wipers

Shaft wipers are ubiquitous across various industries, including automotive, manufacturing, aerospace, and robotics. In automotive applications, they are often used in power steering systems, gearboxes, and suspension components. In manufacturing, precision machinery relies on effective shaft wipers to maintain productivity by reducing downtime caused by contamination.

In the aerospace sector, where reliability is paramount, shaft wipers help maintain the integrity of critical components. Robotics and automation systems utilize these components to ensure that moving parts operate smoothly without the interference of contaminants.

Maintenance Tips

To ensure the longevity and efficiency of shaft wipers, regular inspection and maintenance are crucial. Here are several tips to keep in mind

1. Routine Inspections Regularly check the condition of the wipers for signs of wear, cracks, or deformation. Early detection of wear can prevent costly machinery failures.

2. Clean the Area Keep the surrounding area free from dust and debris. A clean environment reduces the chances of contaminants interacting with the shaft wipers.

3. Replacement Schedule Establish a timely replacement schedule based on the manufacturer's guidelines and the operating conditions of your machinery. This proactive approach can significantly reduce downtime.

4. Lubrication Ensure that the shaft and wiper interface is adequately lubricated, if applicable, to reduce friction and wear on both components.

Conclusion

Shaft wipers are a small yet essential component in maintaining the efficiency and longevity of machinery across various industries. By preventing contamination and ensuring smooth operation, they contribute to overall machinery reliability. Proper maintenance and understanding of their function can lead to significant improvements in operational efficiency, making them a vital consideration for engineers and technicians alike. Investing in high-quality shaft wipers and implementing proactive maintenance strategies will undoubtedly yield positive results in any mechanical application.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories