Feb . 18, 2025 06:21 Back to list

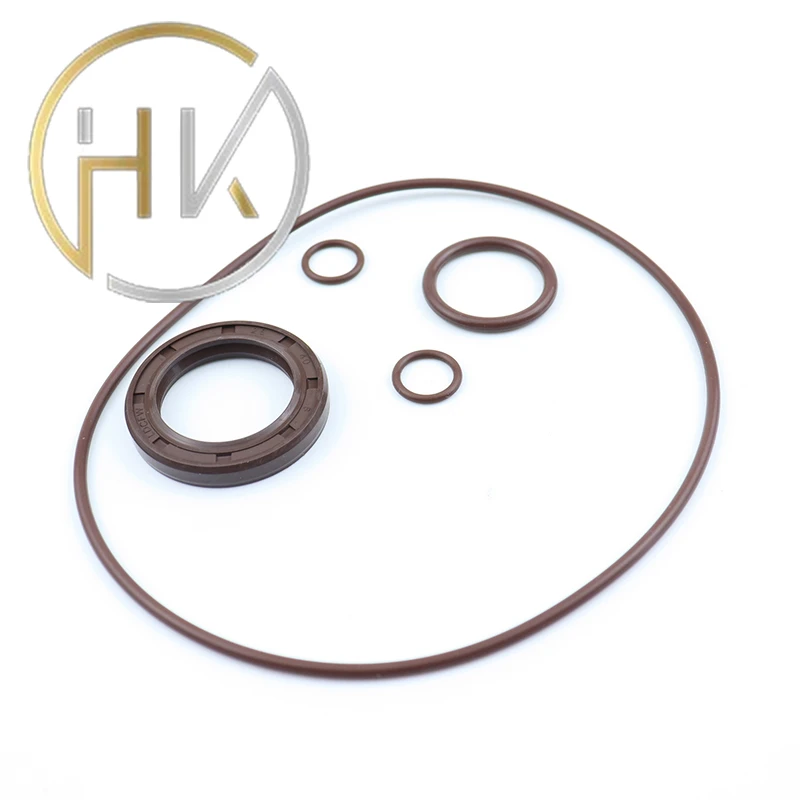

seals and wipers

Authoritativeness in the field of seals and wipers comes from understanding that product innovation is key to addressing modern challenges. Technologies such as self-lubricating seals provide additional benefits by reducing friction and wear, thus increasing efficiency. Companies pioneering in material science have developed seals embedded with sensors that can predict failure, offering predictive maintenance capabilities that are game-changing in preventing system breakdowns. When discussing the trustworthiness of seals and wipers, it is imperative to highlight rigorous testing and quality control processes. Reliable manufacturers comply with industry standards such as ISO/TS 16949 for automotive applications and ISO 9001 for quality management. These certifications assure clients of the product's quality and reliability, instilling confidence in their investment decisions. Opting for a supplier with a proven track record supports operational sustainability and ensures a long-lasting partnership built on trust. Furthermore, real-world case studies illustrate the significant impact of sealing solutions on performance. For example, a leading OEM in the mining industry reported a 30% increase in equipment uptime after replacing traditional seals with custom-engineered solutions. This case underscores the economic and operational advantages of choosing the right sealing and wiping solutions. In conclusion, seals and wipers are integral to optimizing machinery performance and longevity, representing a blend of engineering excellence and strategic material selection. Expertise in their application ensures that they meet the demands of diverse environments while maintaining authoritative standards of quality. Through innovation and stringent quality assurance, these components continue to drive industry progress, proving their worth as the cornerstone of reliable and efficient machinery operation.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories