Nov . 19, 2024 00:58 Back to list

Understanding Cassette Oil Seals and Their Importance in Engine Performance

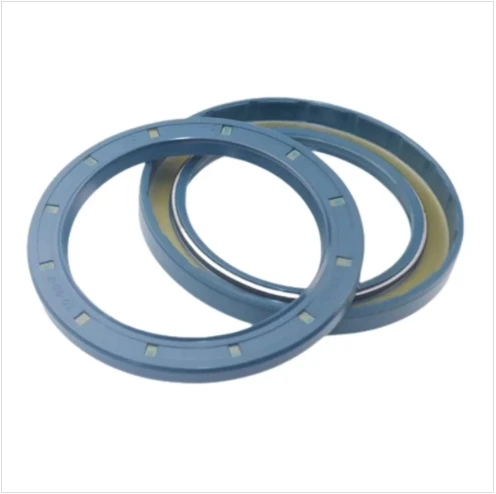

Understanding Cassette Oil Seals Essential Components for Engine Efficiency

Cassette oil seals play a crucial role in the proper functioning of various engines, particularly in automotive applications. These specialized seals are designed to prevent the leakage of lubricating oil while retaining necessary lubricants within specific areas of an engine. In doing so, they enhance the performance and longevity of engine components, ensuring that vehicles operate smoothly and efficiently.

A cassette oil seal is typically made from durable materials such as rubber or elastomers, allowing them to withstand high temperatures and pressures. The design of these seals often incorporates a metal case that provides structural integrity and enables easy installation. This combination of materials ensures that cassette oil seals can resist wear and tear even in demanding environments, which is essential for maintaining optimal engine performance.

One of the primary functions of cassette oil seals is to prevent oil from escaping the engine. Oil leakage can lead to decreased lubrication, resulting in increased friction and wear of engine components. Over time, this can cause serious damage, leading to costly repairs or even engine failure. By keeping the oil contained, cassette oil seals help ensure that engine components are properly lubricated, which is vital for the smooth operation of moving parts.

cassette oil seal

Additionally, cassette oil seals also help to prevent external contaminants, such as dirt and dust, from entering the engine. Contaminants can cause significant damage to engine parts and may lead to a reduction in overall performance. By forming a tight seal, cassette oil seals protect the interior of the engine, promoting a cleaner and more efficient working environment.

Regular maintenance is essential for ensuring the longevity and effectiveness of cassette oil seals. Over time, seals can wear out due to heat cycling, exposure to chemicals, and constant motion. Therefore, routine inspections should be conducted to check for any signs of wear or damage. It is advisable to replace oil seals during regular servicing intervals or whenever other engine components are being repaired or replaced.

In conclusion, cassette oil seals are vital components that significantly contribute to the efficiency and longevity of engines. They effectively contain lubricating oil, prevent leakage, and protect against contaminants, thereby ensuring maximum performance. Understanding their importance can help vehicle owners appreciate the need for regular maintenance and timely replacements, ultimately leading to a more reliable and efficient engine. Whether for personal vehicles or industrial machinery, the role of cassette oil seals cannot be overstated, making them an indispensable part of modern engine design.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories