డిసెం . 02, 2024 05:49 Back to list

radial oil seal

Understanding Radial Oil Seals A Comprehensive Overview

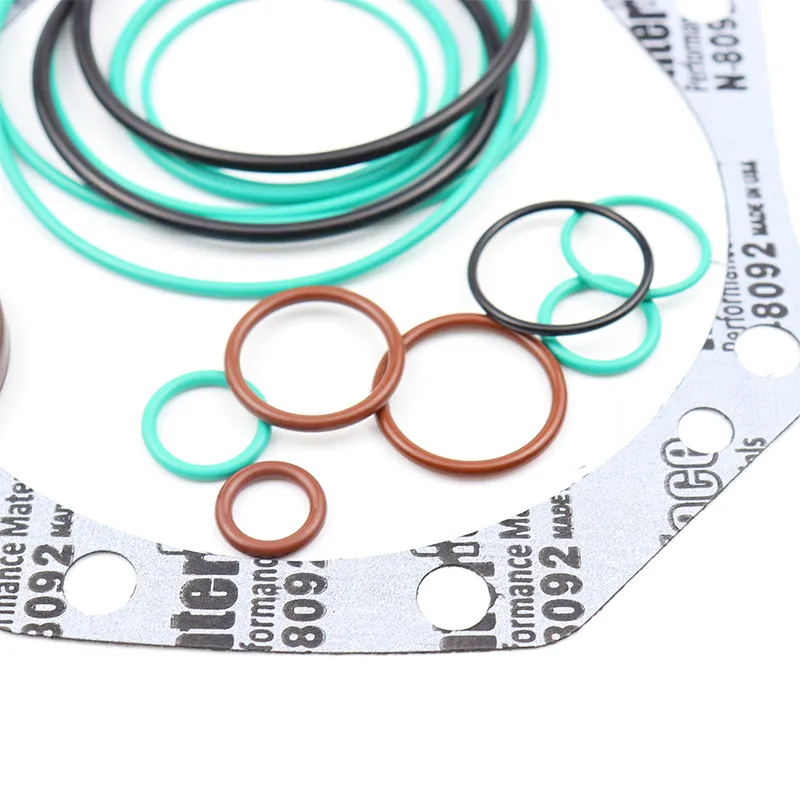

Radial oil seals, also known as radial lip seals or simply oil seals, are an essential component in various mechanical systems, particularly in engines and machinery where lubrication is crucial. Their primary purpose is to retain lubricant while preventing the ingress of contaminants, moisture, and dirt. This article delves into the function, design, applications, and maintenance of radial oil seals.

What Are Radial Oil Seals?

Radial oil seals are typically made of elastomeric materials designed to fit snugly around rotating shafts. They feature a flexible lip that applies pressure against the shaft to create a barrier against oil leakage. This barrier is critical in applications where efficient lubrication is needed to reduce friction and wear between moving parts.

Design and Construction

A radial oil seal consists of several components. The main body is usually constructed from materials like nitrile rubber (NBR), fluorocarbon (FKM), or silicone, chosen based on their compatibility with the specific oil type and operating temperature. The design includes a metal casing for structural integrity, which helps the seal maintain its shape during operation.

One crucial feature is the sealing lip itself, which can be single or double-lipped. A single lip is suitable for many applications, while double-lipped seals provide an additional barrier, making them ideal for environments where oil contamination could occur.

Applications

Radial oil seals are used in various applications across multiple industries. Some common uses include

radial oil seal

2. Industrial Machinery Equipment such as gearboxes, pumps, and hydraulic systems frequently utilize radial oil seals to maintain lubrication and protect internal components from contamination.

3. Aerospace High-performance radial oil seals are employed in aerospace applications where high-temperature resistance and reliability are paramount.

4. Home Appliances Many household appliances, such as washing machines and refrigerators, contain radial oil seals to ensure efficient operation and prevent oil or refrigerants from leaking.

Maintenance and Replacement

Regular inspection and maintenance of radial oil seals are crucial for the longevity of the machinery. Signs of wear or damage may include oil leaks, visible cracks, or hardened rubber. If any of these symptoms are detected, replacing the seal promptly can prevent more severe damage and costly repairs.

Proper installation is also vital. The shaft must be clean and free of burrs to avoid damaging the seal during installation. Additionally, ensuring the correct size and type of seal is used will help maintain the effectiveness of the seal.

Conclusion

In conclusion, radial oil seals play a vital role in maintaining the integrity of mechanical systems by preventing lubricant loss and protecting against contaminants. Their design and materials are tailored to withstand various operational environments, making them a versatile solution for numerous applications. Regular maintenance and timely replacement can significantly enhance the performance and lifespan of equipment, ultimately leading to increased efficiency and reduced operational costs. Understanding the function and importance of radial oil seals is essential for anyone involved in the maintenance or design of mechanical systems.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories