డిసెం . 06, 2024 02:51 Back to list

hydraulic bottle jack repair kits

Understanding Hydraulic Bottle Jack Repair Kits

Hydraulic bottle jacks are essential tools commonly used in various applications, such as lifting vehicles, heavy machinery, and loads in construction and repair industries. These jacks work by employing hydraulic pressure, making them powerful and efficient lifting devices. However, like any mechanical equipment, they can experience wear and tear over time. This is where hydraulic bottle jack repair kits come into play, allowing users to restore their jacks to optimal working condition.

Components of a Hydraulic Bottle Jack Repair Kit

A typical hydraulic bottle jack repair kit contains several essential components needed to troubleshoot and mend issues that may arise. These components usually include

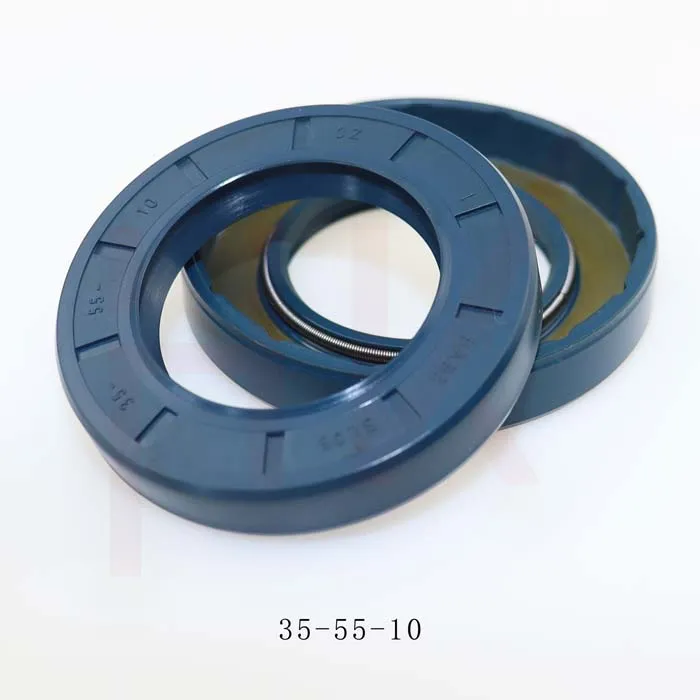

1. Seal Kits These are among the most critical parts of a repair kit. They contain various seals and O-rings designed to prevent fluid leaks. Over time, seals can wear out due to constant pressure and temperature changes, leading to a decrease in the jack's efficiency.

2. Plunger Pins These pins are vital for the jack’s lifting mechanism. If a plunger pin becomes damaged or corroded, it can hinder the smooth operation of the jack. Repair kits often include replacement plunger pins to ensure seamless functionality.

3. Cylinder Components The hydraulic cylinder is the heart of the bottle jack. Repair kits typically feature components such as cylinder liners and gaskets that may require replacement if they have sustained damage or wear.

4. Spring Assemblies Springs help maintain pressure within the hydraulic system. A worn-out or broken spring can lead to inadequate lifting capacity, which makes spring assemblies a crucial part of any repair kit.

5. Spring Retainers These components ensure that springs remain in place and provide the necessary tension for the hydraulic system to operate effectively.

hydraulic bottle jack repair kits

Common Problems and Solutions

Hydraulic bottle jacks can encounter various issues, including fluid leaks, inadequate lifting power, and the inability to hold a load. Here are some common problems and their solutions using repair kits

- Fluid Leaks This is a frequent problem often caused by worn or damaged seals. Inspect the jack for signs of fluid leakage and replace the seals using the components from the repair kit. Ensure the jack is properly cleaned and all old fluid is flushed out before adding new hydraulic fluid.

- Inadequate Lifting Power If the jack struggles to lift a load, check for damage to the plunger or the springs. Replacing these parts with the corresponding items from the repair kit can improve lifting capability.

- Failure to Hold Load If a jack can lift a load but fails to hold it in place, there may be an issue with the seals or springs. Examine these components and replace them as necessary to ensure the jack can maintain its lift.

DIY Repairs vs. Professional Help

For those who are mechanically inclined, using a hydraulic bottle jack repair kit can be a straightforward solution to address common issues. Detailed manuals and online guides often accompany these kits, providing step-by-step instructions for repairs. However, for individuals lacking experience or confidence in performing repairs, it is always advisable to consult a professional technician. This ensures safety and prevents further damage to the equipment.

Conclusion

In conclusion, hydraulic bottle jack repair kits serve as a cost-effective solution for maintaining and extending the life of your hydraulic jacks. By understanding the components included in these kits and recognizing common problems, users can effectively carry out repairs, ensuring their tools remain reliable and functional. Investing in a quality repair kit not only saves money but also promotes safety in operations where hydraulic jacks are employed. Therefore, whether for personal use or in a professional setting, having a hydraulic bottle jack repair kit on hand is a smart choice that pays off in the long run.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories