అక్టో . 02, 2024 16:19 Back to list

High Temperature Oil Seal Solutions for Enhanced Performance and Durability in Extreme Conditions

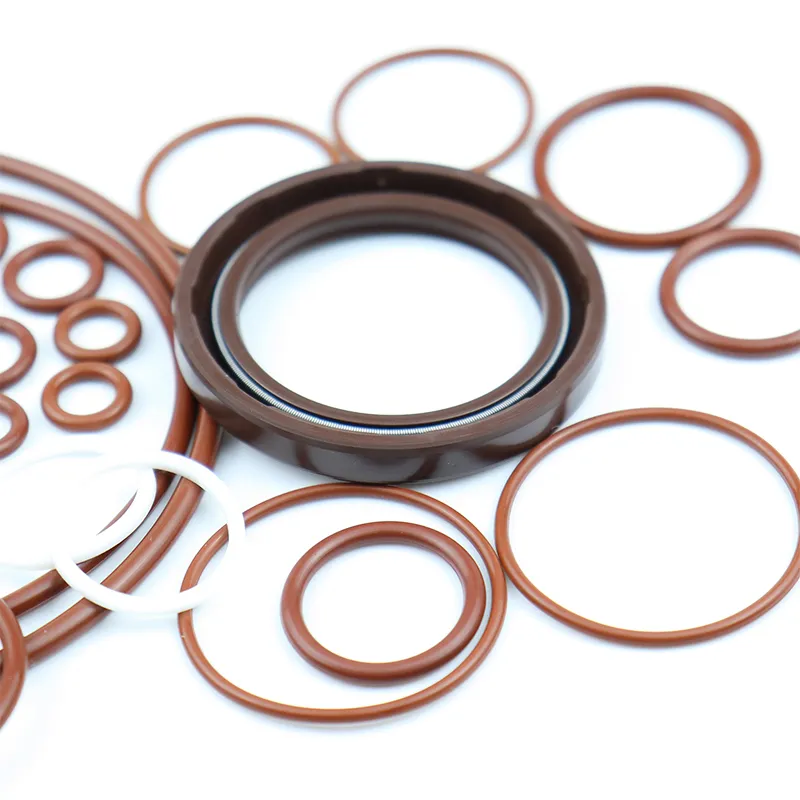

High Temperature Oil Seal An Essential Component for Industrial Applications

In the modern industrial landscape, the functionality and reliability of machinery are paramount to operational efficiency and safety. Among the many components that play a critical role in ensuring mechanical systems run smoothly, high-temperature oil seals stand out as essential elements for various applications. These seals are engineered to contain lubricants and prevent fluid leakage, all while withstand collateral mechanical and thermal stress.

What is a High-Temperature Oil Seal?

High-temperature oil seals are specially designed components that serve to seal a rotating shaft within machinery. Their primary function is to retain lubricants while preventing contaminants such as dirt, dust, and moisture from entering the internal working parts of machinery. Unlike standard oil seals, high-temperature variants are crafted from materials that can endure extreme thermal conditions, making them suitable for environments that exceed typical operational temperatures.

Material Composition

The selection of materials for high-temperature oil seals is critical to their performance. Commonly used materials include fluoroelastomers like FKM (Viton), silicone rubber, and specially designed PTFE (Polytetrafluoroethylene). Each of these materials offers robust thermal stability, oil resistance, and mechanical strength. FKM, for instance, maintains performance at temperatures up to 200°C (392°F), while silicone can function effectively even at temperatures as high as 250°C (482°F). The right material choice is crucial, depending on the specific working conditions and the type of lubricants used.

Applications

high temperature oil seal

High-temperature oil seals find extensive applications across various industries, including automotive, aerospace, manufacturing, and energy. In the automotive sector, these seals are vital for engines, transmissions, and power steering systems where temperatures can fluctuate significantly during operation. In aerospace, they ensure the reliability of hydraulic systems under extreme conditions, whereas in manufacturing, they play a crucial role in machinery such as pumps, compressors, and heavy-duty gearboxes.

Furthermore, in the energy sector, particularly in oil and gas extraction, high-temperature oil seals are employed in drilling equipment and processing systems. These applications underscore the versatility and critical nature of high-temperature oil seals in maintaining system integrity.

Challenges Faced

Despite their robustness, high-temperature oil seals face several challenges. One of the principal issues is thermal deformation, which can occur if the seal material is not suitable for the specific temperature range encountered in operation. Additionally, exposure to aggressive chemicals or abrasive particles can lead to premature wear, compromising the seal's effectiveness.

Preventive measures, including regular inspection and maintenance, are essential in combating these challenges. Implementing a proactive maintenance schedule can help identify potential problems before they escalate, ensuring the longevity and reliability of the seals.

Conclusion

High-temperature oil seals are vital components in ensuring the efficient operation of machinery across various high-demand industries. Their ability to withstand extreme temperatures and maintain a reliable seal is pivotal for preventing leaks and ensuring the smooth functioning of mechanical systems. As industries continue to push the boundaries of operational efficiency and performance, the significance of well-engineered high-temperature oil seals will only increase. It is crucial for engineers and maintenance teams to choose the right materials and stay ahead of maintenance practices to maximize the benefits offered by these essential components. With proper management, high-temperature oil seals can provide unparalleled durability and reliability, contributing to the overall performance and safety of industrial operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories