సెప్టెం . 11, 2024 20:56 Back to list

High-Quality 25x35x7 Oil Seal - Reliable Sealing Solutions

Understanding the 25x35x7 Oil Seal A Crucial Component in Machinery

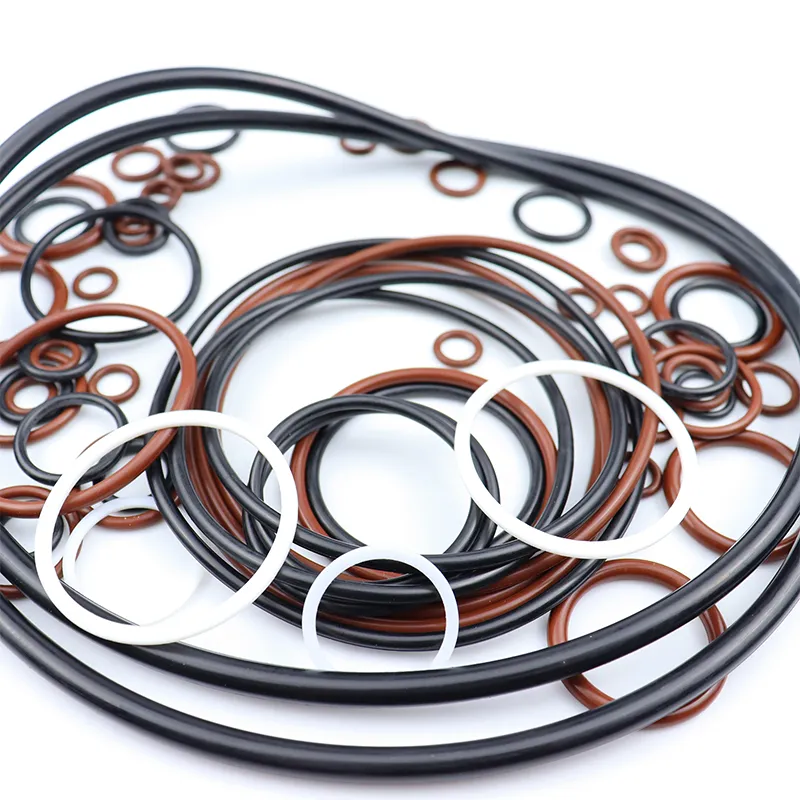

Oil seals, also known as shaft seals or lip seals, play a vital role in machinery and automotive applications. They are designed to prevent the leakage of lubricants and protect the internal components from external contaminants. Among the various types of oil seals available, the 25x35x7 oil seal is particularly noteworthy due to its specific dimensions and applications.

The designation 25x35x7 refers to the oil seal's dimensions in millimeters. The first number, 25, represents the inner diameter of the seal, which is typically designed to fit onto a shaft or a rotating component. The second number, 35, indicates the outer diameter of the seal, which provides a fit against the housing where the seal is installed. Finally, the last number, 7, specifies the width or thickness of the seal. These dimensions help ensure a snug fit that is crucial for maintaining the effective sealing capabilities of the oil seal.

The primary function of the 25x35x7 oil seal is to contain lubricant within the machine while preventing the intrusion of dirt, dust, and moisture

. This is essential in maintaining the integrity and performance of machinery, as any leakage can lead to premature wear and tear of components, resulting in costly repairs and downtime. Furthermore, contaminants can severely affect the performance of lubricants, leading to increased friction and overheating within the machinery.25x35x7 oil seal

Manufactured from durable materials such as rubber, polyurethane, or silicone, the 25x35x7 oil seal is designed to withstand a range of temperatures and pressures. The lip of the seal is engineered to maintain contact with the shaft, providing a barrier that minimizes leakage while accommodating any slight movement or vibrations that may occur during operation.

Applications for the 25x35x7 oil seal are extensive. It is commonly used in automotive engines, gearboxes, and various industrial machinery. Its versatility also makes it suitable for use in agricultural equipment, motorcycles, and hydraulic systems.

When selecting an oil seal, it is essential to consider the operating conditions, such as temperature, pressure, and the type of lubricant used. Proper installation is also critical; even a small misalignment can compromise the seal's effectiveness.

In conclusion, the 25x35x7 oil seal is an integral component in many mechanical systems. By ensuring proper sealing and protection against contaminants, it helps maintain the efficiency and longevity of machines. As such, understanding its function and application is essential for anyone involved in machinery maintenance and repair. Whether in an automotive workshop or an industrial setting, the importance of reliable oil seals cannot be overstated.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories