ஜூலை . 27, 2024 15:16 Back to list

Understanding the Importance of Cassette Oil Seals in Engine Performance and Maintenance

Understanding Cassette Oil Seals Their Importance and Functionality

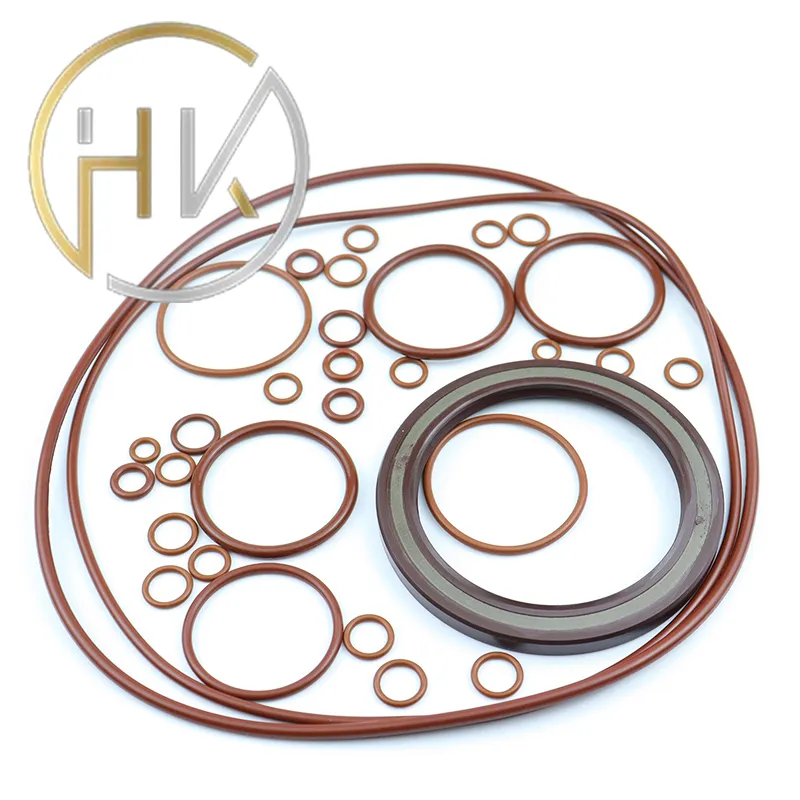

In the realm of mechanical engineering and automotive design, the importance of oil seals cannot be overstated. Among the various types of oil seals, cassette oil seals stand out due to their unique design and functionality. These seals play a crucial role in ensuring the efficiency and longevity of machinery by preventing oil leaks and contamination.

Cassette oil seals, often referred to as rotary seals or shaft seals, are specifically engineered to seal rotating shafts in various applications, including automotive engines, transmissions, and other machinery. Their design typically includes a flexible lip that creates a tight seal against a rotating shaft, thereby preventing the escape of lubricants and the ingress of dirt, water, and other contaminants.

One of the most significant advantages of cassette oil seals is their ability to withstand high temperatures and pressures, which are common in many industrial applications. Made from durable materials such as rubber, silicone, or polyurethane, these seals can function effectively in harsh environments. Depending on the specific application, the selection of material for the seal can vary. For instance, high-performance engines may require seals that can endure higher temperatures and provide greater resistance to wear and tear.

Installation of cassette oil seals is a critical process that can influence their performance and lifespan. Improper installation can lead to misalignment, which may result in leaks or premature failure of the seal. It is essential to ensure that the sealing lip is adequately lubricated and positioned correctly during assembly. Many manufacturers provide detailed instructions to help mechanics and engineers achieve a perfect installation.

cassette oil seal

Maintenance of machines incorporating cassette oil seals is also vital. Regular inspections should be conducted to check for signs of wear, such as cracks or deformation of the seal. In addition, monitoring fluid levels and checking for leaks can help catch issues before they escalate, ensuring the continued operation of the equipment without catastrophic failures.

The functionality of cassette oil seals extends beyond mere sealing. They contribute to the overall efficiency of the mechanical system by reducing friction between the rotating shaft and the seal. This reduction in friction not only minimizes wear on both the shaft and the seal but also enhances fuel efficiency in automotive applications. A well-functioning oil seal can lead to improved performance and lower operational costs in the long run.

Another noteworthy aspect of cassette oil seals is their versatility. These seals come in various sizes and configurations to accommodate a wide range of machinery and applications. From small automotive engines to large industrial equipment, cassette oil seals can be customized to meet specific needs, making them integral components across various sectors.

In conclusion, cassette oil seals are indispensable in maintaining the integrity and performance of rotating machinery. Their ability to prevent leaks, withstand harsh conditions, and reduce friction highlights their importance in engineering and manufacturing. As industries continue to evolve and demand higher efficiency and reliability from their machinery, the role of cassette oil seals will remain critical. Understanding their functionality, benefits, and maintenance requirements ultimately leads to better choices in machinery design and fosters innovations that rely on reliable sealing solutions. As we move forward, the continued evolution of materials and technologies in the field of oil seals will undoubtedly enhance performance and sustainability in various applications.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories