ஜன . 09, 2025 10:37 Back to list

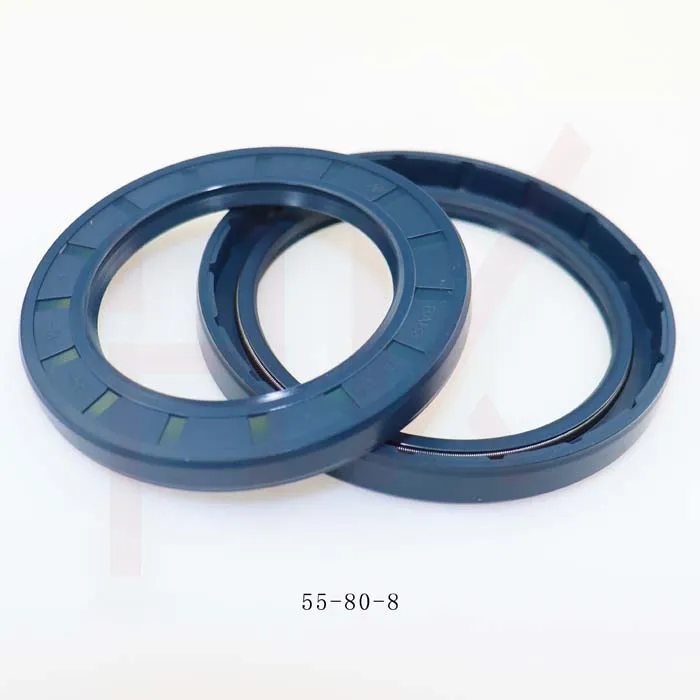

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

Delving deeper into the authority of a factory, customer feedback and case studies can be telling indicators. A factory that has successfully partnered with other giants in the field, evidenced by reviews and documented success stories, positions itself as a trustworthy companion for future ventures. Their collaborative endeavors and the solutions provided in challenging scenarios speak volumes about their reliability and adaptability. Trustworthiness is further established through transparent business practices. From sourcing premium materials ethically to adopting sustainable production methods, an oil seal factory's practices reflect its dedication to responsibility and customer satisfaction. A factory that invites potential clients for plant tours, offers direct consultations with engineers, and transparently discusses production timelines and costs exemplifies trust and accountability. Finally, a seamless logistics operation can make a significant difference. Proficiency in navigating the complexities of global supply chains ensures that no matter where your operations are based, your supplies will arrive on time. A factory’s readiness to adapt to quick changes in order specifications or delivery deadlines showcases their commitment to customer-centric service. In conclusion, the right oil seal factory offers more than just products. It serves as a partner imbued with rich experience, specialized expertise, and steadfast reliability. Navigating this partnership with careful consideration can propel your enterprise, offering improved efficiencies and sustained trust in your operational framework.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories