ஜன . 06, 2025 18:47 Back to list

oil seal factory

Unveiling the Core of Quality Insights into the Leading Oil Seal Factory

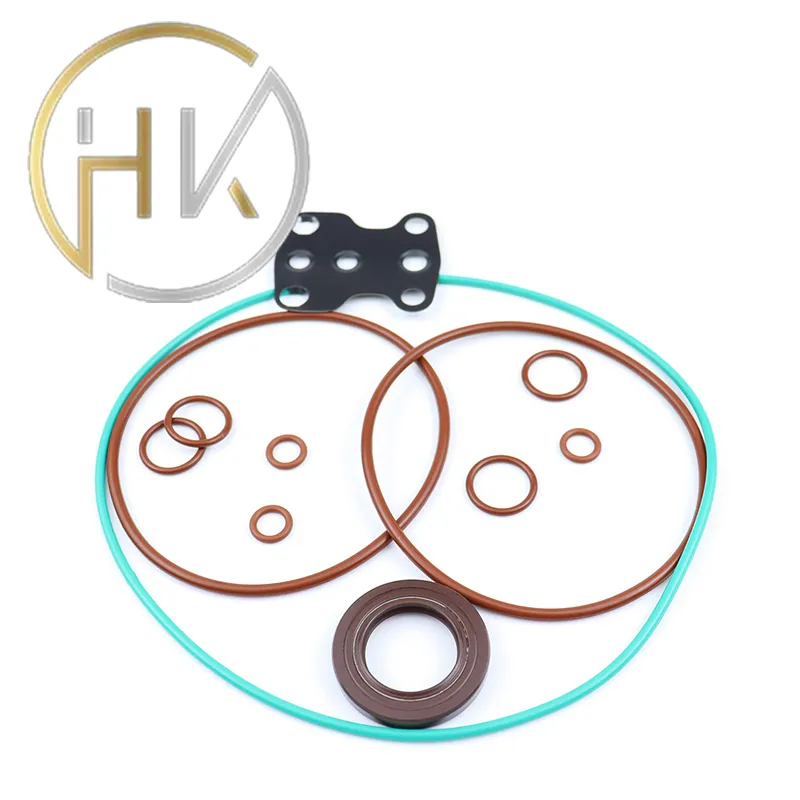

In the heart of industrial manufacturing, oil seal factories play a pivotal role, producing essential components that ensure machinery across various sectors runs smoothly. An expedition into the operations and ethos of a leading oil seal factory reveals not just the technical expertise and high standards maintained, but also underscores the significance these factories hold within the supply chain ecosystem.

With decades of experience, a premier oil seal factory blends traditional craftsmanship with cutting-edge technology to meet the diverse needs of its global clientele. The factory's commitment to quality starts with the meticulous selection of raw materials. Only the finest rubbers and metals, known for their durability and resilience, are chosen to withstand the harshest conditions in machinery operations. This foundational step ensures that each oil seal produced is robust and reliable, capable of preventing leakages and maintaining the integrity of machinery systems.

The factory prides itself on its team of highly skilled engineers and technical experts. With a deep understanding of both legacy and contemporary machinery, this team is instrumental in driving innovation. They continuously engage in research and development, seeking to improve the efficiency and lifespan of oil seals. This expertise is evident in the custom solutions the factory provides, tailoring oil seals to fit unique and specific client needs, thereby addressing challenges that off-the-shelf products cannot solve.

oil seal factory

At the heart of this factory's operations is an authoritative quality control system. Every oil seal undergoes rigorous testing procedures, adhering to international standards. These tests ensure the products can endure temperature extremes, high-pressure environments, and chemical exposures without compromising performance. Such thorough scrutiny reaffirms the factory’s position as a leader in manufacturing excellence, instilling confidence in clients worldwide.

Trustworthiness is built not only on product quality but also on the factory’s transparency and customer service ethos. Clients are offered a clear channel of communication, with detailed insights into production timelines and quality benchmarks. The factory’s customer service team is trained to handle inquiries thoroughly and professionally, providing clients with timely updates and support throughout the purchasing process.

Furthermore, the factory’s commitment to sustainability sets it apart. Recognizing the environmental impact of industrial operations, the factory has implemented eco-friendly practices. Waste reduction strategies, energy-efficient processes, and a robust recycling protocol are integrated into daily operations. The factory’s dedication to reducing its carbon footprint appeals to environmentally conscious clients and aligns with global movements towards sustainable manufacturing practices.

In summary, a leading oil seal factory distinguishes itself through a seamless blend of experience, expertise, authority, and trustworthiness. From the raw materials to the finished product, every step is executed with precision and care. This commitment to excellence not only ensures the production of superior oil seals but also fortifies the factory’s reputation as a trusted partner in industrial solutions, supporting the seamless operation of machinery worldwide.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories