டிசம்பர் . 14, 2024 12:03 Back to list

metric wiper seals

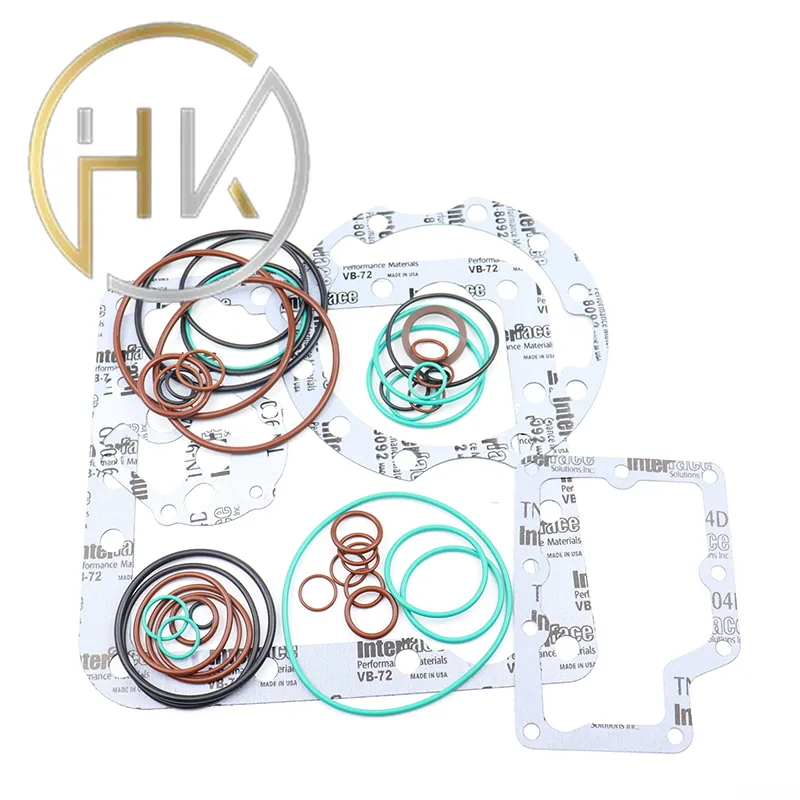

Understanding Metric Wiper Seals Essential Components for Fluid Power Systems

Metric wiper seals are critical components in hydraulic and pneumatic systems, playing a significant role in maintaining efficiency and prolonging the lifespan of machinery and equipment. Designed to fit tightly in the housing of piston rods or cylinders, these seals effectively prevent contaminants such as dirt, dust, and moisture from entering the assembly while keeping hydraulic or pneumatic fluid from leaking out. This article explores the importance, design, and applications of metric wiper seals in various industries.

What Are Wiper Seals?

Wiper seals, sometimes referred to as scraper seals, are sealing devices primarily used in dynamic applications where they must withstand considerable movement. They are typically positioned at the outer edge of hydraulic and pneumatic cylinders. The primary function of these seals is to wipe off any debris or contaminants from the surface of the rod as it moves in and out of the cylinder. This ensures that the internal components of the system remain clean, ultimately enhancing operational reliability.

Importance of Metric Wiper Seals

1. Contamination Control One of the main threats to the efficiency of fluid power systems is contamination. Particles entering the hydraulic or pneumatic system can lead to wear and tear of internal components, resulting in costly repairs and downtime. Metric wiper seals create a barrier that limits the ingress of harmful particles, thus preserving the integrity of the system.

2. Leak Prevention In addition to preventing contamination, wiper seals also help retain the necessary fluid within the system. By creating a tight seal, they minimize the risk of leaks, which can lead to fluid loss and reduction in system performance.

3. Performance Optimization Maintaining optimal performance in machinery is essential. The presence of contaminants can cause increased friction, reduced efficiency, and premature failure of parts. By ensuring a clean operating environment, metric wiper seals contribute to smoother operation and improved performance of hydraulic and pneumatic systems.

Design Features

Metric wiper seals are carefully engineered for specific applications. They come in various shapes, sizes, and materials to meet different operational demands. Here are some key design features

- Material Common materials for wiper seals include polyurethane, rubber, and PTFE (Teflon). Each material offers unique properties such as resistance to abrasion, temperature variations, and chemical substances, making it crucial to choose the right material based on the application.

metric wiper seals

- Profile The design profile of wiper seals influences their wiping action. Various profiles are available, including flat, lip, and angled shapes, enabling them to accommodate different rod diameters and operating conditions.

- Clearance and Fit Proper clearance between the seal and the rod is essential to ensure effective wiping while minimizing wear on both the seal and the rod. Manufacturers often provide detailed specifications to ensure an optimal fit.

Applications of Metric Wiper Seals

Metric wiper seals find applications across a diverse range of industries, including

- Automotive In hydraulic systems of vehicles, such as brakes and power steering, wiper seals help maintain fluid integrity and prevent contamination.

- Manufacturing Machinery used in manufacturing processes relies heavily on hydraulic systems. Wiper seals protect these systems from harsh working conditions.

- Construction Equipment Heavy equipment like excavators and loaders continuously face exposure to dirt and debris, making wiper seals essential for their hydraulic systems to function effectively.

- Aerospace In aerospace applications, the reliability of hydraulic systems is paramount. Metric wiper seals ensure optimal performance and safety.

Conclusion

Metric wiper seals are indispensable for the longevity and efficiency of hydraulic and pneumatic systems. By preventing contamination and fluid leaks, they play a crucial role in maintaining operational reliability across various industries. As technology continues to evolve, the design and materials used for wiper seals will likely advance, further enhancing their performance and applicability in diverse environments. Understanding the importance of these seals can lead to better maintenance practices and greater investment in the machinery that drives modern industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories