டிசம்பர் . 15, 2024 00:20 Back to list

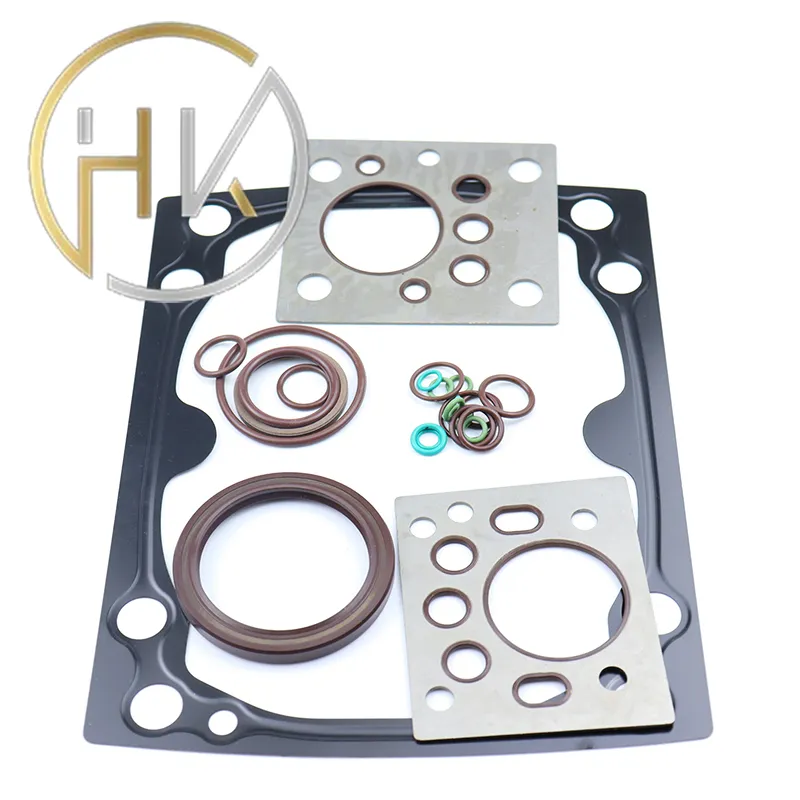

hydraulic cylinder repair seals

Hydraulic Cylinder Repair Seals and Their Importance

Hydraulic systems are integral to a myriad of industrial and commercial applications, providing powerful movement and control. At the heart of these systems lies the hydraulic cylinder, which converts hydraulic energy into mechanical force. However, like any mechanical system, hydraulic cylinders can experience wear and tear over time, particularly with their seals. Proper maintenance and timely repair of hydraulic cylinder seals are essential for ensuring optimal performance and prolonging the lifespan of the equipment.

Understanding Hydraulic Cylinder Seals

Seals in hydraulic cylinders serve a crucial role. They prevent hydraulic fluid from leaking out of the cylinder and keep contaminants from entering the system. Without these seals, the hydraulic fluid would escape, leading to a loss of pressure and efficiency. This could result in erratic operation or complete failure of the hydraulic system, which can be costly both in terms of repairs and downtime.

There are various types of seals used in hydraulic cylinders, including O-rings, U-cups, and lip seals. Each type serves a specific function and is suited for different pressure and environmental conditions. Understanding the characteristics and applications of these seals is vital for anyone involved in hydraulic system maintenance and repair.

Signs of Seal Failure

Recognizing the signs of seal failure can help prevent more extensive damage to hydraulic cylinders. Common indicators include

1. Leaking Fluid The most apparent sign of a seal failure is the presence of hydraulic fluid leaking from the cylinder. This not only reduces system efficiency but also poses environmental hazards.

2. Reduced Performance If the hydraulic cylinder is underperforming, such as slow operation or weak force output, it may be a sign of seal degradation.

3. Increased Noise Unusual noises coming from the hydraulic cylinder, such as grinding or rattling, can indicate that the seals are not functioning correctly.

4. Contamination If dirt or debris is found in the hydraulic fluid, it suggests that the seals are compromised, allowing contaminants to enter the system.

Repairing Hydraulic Cylinder Seals

hydraulic cylinder repair seals

Repairing hydraulic cylinder seals involves several steps. First, it is essential to diagnose the issue accurately. This may involve inspecting the cylinder for wear, checking the fluid for contaminants, and determining the specific type of seals used.

Once the problem is identified, the repair process begins. This typically includes

1. Disassembly The hydraulic cylinder must be carefully disassembled to access the seals. It is crucial to document the assembly order to ensure proper reassembly.

2. Inspecting Components Once disassembled, all components should be inspected for wear or damage, including the rod, barrel, and seals. Any damaged parts should be replaced.

3. Replacing Seals The old seals need to be removed and replaced with new ones. It is essential to choose seals that meet the specifications of the hydraulic system to ensure proper function.

4. Reassembly and Testing After replacing the seals and any damaged components, the cylinder is reassembled. It should then be tested under operating conditions to ensure that repairs were successful and that there are no leaks.

Preventive Measures

To minimize the risk of seal failure, regular maintenance is essential. This includes

- Regular inspections of hydraulic systems - Monitoring fluid levels and quality - Lubricating components as recommended - Keeping the system clean and free of contaminants

Implementing a proactive maintenance program can significantly reduce the likelihood of seal failure, improve efficiency, and extend the life of hydraulic cylinders.

Conclusion

In conclusion, the seals in hydraulic cylinders are critical components that require careful attention. Understanding their function, recognizing failure signs, and executing timely repairs can ensure the effective operation of hydraulic systems. By investing in regular maintenance and repairs, businesses can save on costs and enhance productivity, making hydraulic systems more reliable and efficient in their operations.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories