நவ் . 21, 2024 21:22 Back to list

high temperature o ring kit

The Importance of High-Temperature O-Ring Kits in Modern Applications

In a world where technology is evolving at an unprecedented rate, the need for reliable and efficient sealing solutions has never been more critical. One of the most versatile components in this arena is the O-ring. Specifically, high-temperature O-ring kits have emerged as essential tools across various industries, including aerospace, automotive, oil and gas, and manufacturing. This article explores the significance of high-temperature O-ring kits, their applications, materials, and the benefits they offer.

Understanding O-Rings

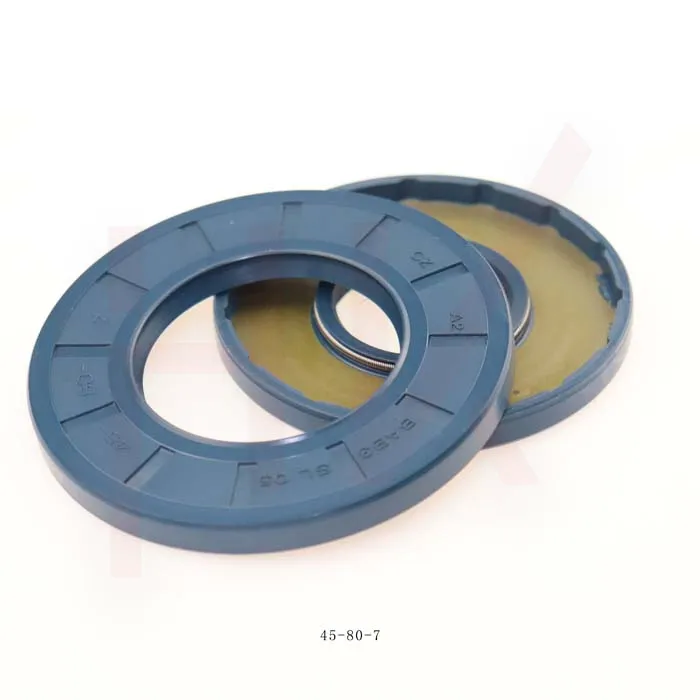

O-rings are simple, yet crucial, mechanical seals that are designed to prevent the leakage of fluids or gases between two mating surfaces. They come in various shapes, sizes, and materials, tailored to withstand different environmental conditions. Among the variants, high-temperature O-rings are specifically engineered to maintain their integrity and functionality in extreme heat conditions, making them suitable for demanding applications.

Applications of High-Temperature O-Ring Kits

1. Aerospace Industry In the aerospace sector, machinery and components are often subjected to high temperatures during operation. O-rings are used in fuel systems, hydraulic systems, and engine components to ensure that fluids do not leak under extreme conditions. The reliability of these seals is crucial for safety and performance.

2. Automotive Sector High-temperature O-rings are commonly found in vehicles, particularly in engines and exhaust systems. They function to keep oil, coolant, and gases contained, which is vital for the efficiency and longevity of the engine. As vehicles evolve with more powerful engines, the demand for effective sealing solutions increases.

3. Oil and Gas Industry In this sector, equipment operates under very high temperatures and pressures. High-temperature O-rings are critical in drilling equipment, pipelines, and valves, where they prevent leaks and ensure safe operations. The harsh conditions of oil extraction necessitate robust sealing solutions that can endure thermal cycling and aggressive chemicals.

4. Industrial Applications Many manufacturing processes involve high-temperature conditions. O-rings are used in presses, molding machines, and other equipment to maintain sealing integrity. Their ability to withstand thermal stress ensures operational efficiency and product quality.

Material Selection for High-Temperature O-Rings

The performance of high-temperature O-rings largely depends on the materials used in their construction. Common materials include

high temperature o ring kit

- Fluoroelastomer (FKM) Known for its outstanding heat resistance and chemical stability, FKM can operate effectively in temperatures up to 200°C (392°F) and beyond

. Its properties make it suitable for various applications in the aerospace and automotive industries.- Silicone Silicone O-rings are another popular choice for high-temperature applications. They can typically withstand temperatures between -100°C to 200°C (-148°F to 392°F). Silicone is particularly effective in environments where flexibility is required at high temperatures.

- Polyurethane While not as common as FKM and silicone, polyurethane O-rings can also handle high temperatures while providing excellent abrasion resistance. They are often used in dynamic sealing applications.

Benefits of High-Temperature O-Ring Kits

Investing in high-temperature O-ring kits offers several advantages

1. Enhanced Safety Reliable seals prevent leaks that could lead to hazardous situations, especially in industries dealing with flammable or toxic materials.

2. Operational Efficiency Effective sealing minimizes the risk of downtime or repairs, allowing equipment to run smoothly and efficiently.

3. Cost-Effectiveness With the right O-ring materials and designs, companies can achieve long-lasting seals, reducing the frequency of replacements and maintenance costs.

4. Versatility High-temperature O-ring kits come in various sizes and materials, making them adaptable to numerous applications across different sectors.

Conclusion

High-temperature O-ring kits play a vital role in today's industrial landscape. Their ability to withstand extreme conditions ensures the safe and efficient operation of various systems, from aerospace to automotive. As industries continue to embrace advancements in technology, the demand for reliable sealing solutions like high-temperature O-rings will undoubtedly grow. Investing in quality O-ring kits is essential for maintaining productivity, safety, and operational excellence in any high-performance application.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories