நவ் . 25, 2024 04:00 Back to list

Excavator Seal Solutions for Improved Performance and Durability

The Importance of Excavator Seals in Heavy Machinery Maintenance

Excavators are essential machines in the construction and excavation industries, used for digging, lifting, and various other heavy-duty tasks. These machines are subjected to extensive workloads, making their durability and efficiency paramount. A critical component of ensuring that an excavator operates optimally is the seal system, which plays a vital role in maintaining hydraulic integrity and preventing leaks. This article explores the significance of excavator seals, their functions, types, and maintenance practices.

The Function of Excavator Seals

Excavator seals serve multiple purposes in the hydraulic systems of these machines. Their primary function is to prevent fluid leaks by creating a barrier between moving parts that must remain lubricated while keeping contaminants out. Hydraulic systems operate under high pressures, and any leakage can lead to reduced efficiency, increased wear and tear on components, and ultimately, machinery failure.

Seals also help maintain pressure within hydraulic cylinders, ensuring consistent power delivery to the machine's various functions, such as the boom, arm, and bucket. The effectiveness of these seals directly correlates to the overall operational efficiency and longevity of the excavator.

Types of Excavator Seals

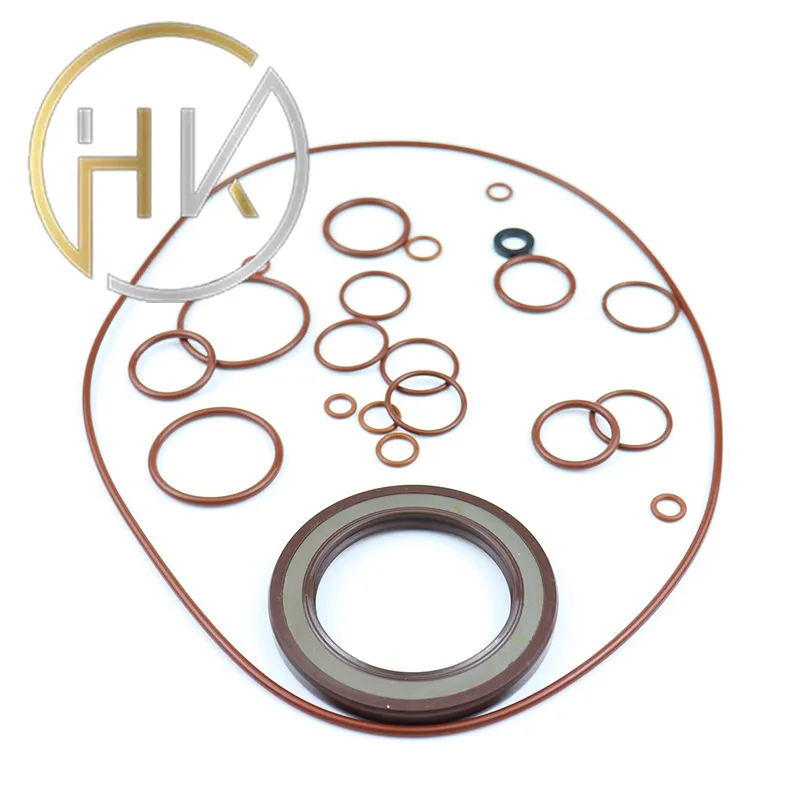

Excavator seals come in various types, each designed for specific applications and functions. Common types include

1. O-Rings These are circular seals that fit into grooves and provide a simple, effective means of sealing against fluid leakage. O-rings are often used in hydraulic cylinders and other critical connections.

2. U-Cups Shaped like the letter U, these seals are used to manage pressures from both sides of a moving component. They are particularly effective in preventing fluid bypass.

3. Rod Seals These are specifically designed for hydraulic cylinders, sealing the area between the piston rod and cylinder wall. They prevent leaks while allowing for smooth rod movement.

4. Gland Seals These seals are typically used at the ends of hydraulic cylinders to provide an additional barrier against leaks.

excavator seal

5. Dust Seals Unlike hydraulic seals, dust seals are not designed to retain hydraulic fluid but rather to protect the hydraulic components from dirt, dust, and other contaminants that can cause wear.

The Importance of Seal Maintenance

Regular maintenance of excavator seals is crucial to ensure the machine operates efficiently. Over time, seals can wear out, harden, or become damaged, leading to leaks and reduced hydraulic performance. Here are some maintenance practices to consider

1. Regular Inspections Routine checks on seals for signs of wear, swelling, or damage can help identify issues before they lead to significant problems. Inspecting the seals during regular maintenance sessions ensures that any deteriorating seals are replaced promptly.

2. Fluid Quality Maintaining high-quality hydraulic fluid is vital for seal longevity. Contaminated or degraded hydraulic fluid can damage seals and shorten their lifespan.

3. Environmental Considerations When working in particularly harsh environments, extra care should be taken to protect seals from extreme temperatures and aggressive contaminants. This might involve using specialized seals designed for high-stress conditions.

4. Proper Installation Ensuring that seals are properly installed is essential. Incorrect installation can lead to immediate and severe leakage issues. Following manufacturer specifications during replacements and repairs is crucial.

5. Training and Knowledge Operators and maintenance personnel should be trained in the importance of seals and how to manage them effectively. This knowledge can prevent unnecessary damages and extend the life of the excavator.

Conclusion

Excavator seals play a pivotal role in the performance and reliability of these critical machines. Their ability to prevent leaks, facilitate hydraulic pressure, and keep contaminants at bay cannot be overstated. By prioritizing proper seal maintenance and being proactive in inspections and replacements, operators can ensure that their excavators run efficiently, thereby maximizing productivity and minimizing downtime. Understanding and respecting this integral component of heavy machinery will ultimately lead to better operational outcomes and prolonged equipment life.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories