நவ் . 08, 2024 09:59 Back to list

Equivalent 25x35x7 Oil Seal Specifications and Applications for Mechanical Equipment

Understanding the 25x35x7 Oil Seal Importance, Applications, and Selection Guide

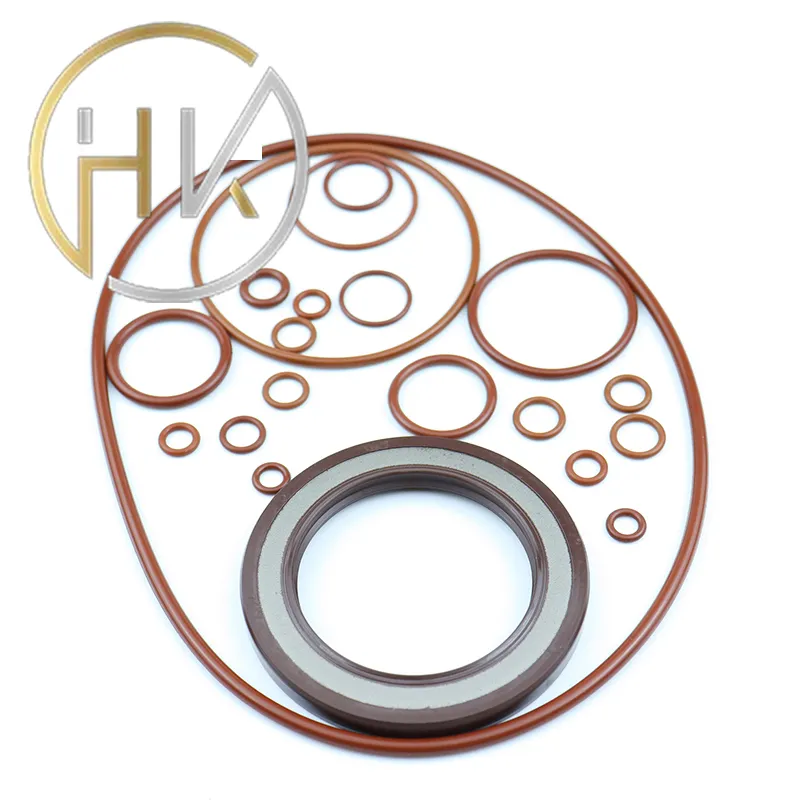

Oil seals are essential components in mechanical systems, designed to prevent lubricant leakage and to keep contaminants out. The 25x35x7 oil seal, characterized by its dimensions and specific features, plays a significant role in various applications across industries such as automotive, manufacturing, and machinery. This article will delve into the importance of this oil seal, its applications, and key factors to consider when selecting the right one for your needs.

What is the 25x35x7 Oil Seal?

The designation 25x35x7 indicates the dimensions of the oil seal in millimeters. Specifically, the first number represents the inner diameter (ID), the second number the outer diameter (OD), and the last number the thickness of the seal. In this case, the 25x35x7 oil seal has an internal diameter of 25 mm, an external diameter of 35 mm, and a thickness of 7 mm. This size makes it versatile for a range of applications where a tight seal is necessary to maintain fluid integrity.

Importance of Oil Seals

Oil seals serve a critical function in ensuring the longevity and efficiency of machinery. By effectively sealing the lubricants within, they prevent leaks that can lead to reduced lubrication and potential damage to components. Furthermore, they keep dirt, dust, and other contaminants from entering sensitive areas of a machine, which can lead to wear and tear. In other words, the right oil seal can significantly enhance the performance and lifespan of machinery.

Applications of the 25x35x7 Oil Seal

The 25x35x7 oil seal is commonly used in various applications, including

1. Automotive Components In vehicles, oil seals are used in engines, gearboxes, and differentials. They help in containing oil and preventing leakage, which is crucial for maintaining engine performance and efficiency.

2. Industrial Machinery Oil seals are vital in manufacturing equipment and machinery that utilize lubricants. They protect critical components such as bearings and shafts from contamination.

3. Hydraulic Systems Oil seals are used in hydraulic equipment, serving to prevent fluid leakage and maintaining pressure within the system, which is essential for functionality.

25x35x7 oil seal

4. Power Tools Many power tools utilize oil seals to ensure that lubricants remain where they are needed most, enhancing both performance and durability.

5. Household Appliances Common household appliances, such as refrigerators and washing machines, also employ oil seals to maintain internal fluids and prevent leaks.

Key Factors for Selecting the Right Oil Seal

When selecting the appropriate oil seal, there are several critical factors to consider

1. Material Oil seals can be made from various materials such as rubber, polyurethane, or felt. The choice of material depends on the operating environment, including factors like temperature, pressure, and exposure to chemicals.

2. Operating Conditions Consider the operational temperature range, speed, and difficulty of the environment in which the oil seal will be used. This can significantly influence the seal's longevity and performance.

3. Type of Lubricant Different lubricants may have varying impacts on seal materials. Ensure that the chosen material is compatible with the fluids it will encounter.

4. Design The design of the oil seal, including the presence of springs or special lip configurations, can affect sealing performance. Select a design that meets the specific requirements of your application.

5. Installation Proper installation is crucial for effective sealing. Ensure that the oil seal is installed according to manufacturer guidelines to avoid any premature failure.

Conclusion

The 25x35x7 oil seal is an indispensable component that finds applications across diverse industries. Understanding its importance and the factors to consider in selecting the right seal can lead to improved performance and increased durability of machinery. Whether in automotive or industrial settings, ensuring that you have the appropriate oil seal in place can save costs and enhance operational reliability. Always consider the specific needs of your application and consult with experts to ensure optimal performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories