நவ் . 27, 2024 15:23 Back to list

Similar Oil Seal Specifications for Improved Performance and Reliability in Machinery Applications

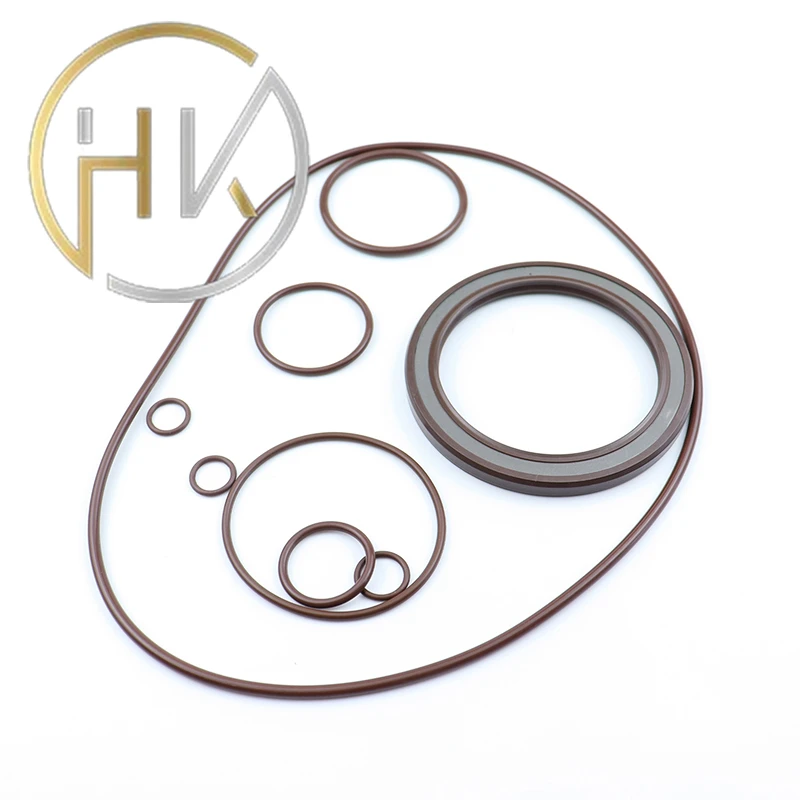

Understanding the Importance of the 25% 2035 7 Oil Seal

In the world of mechanical engineering and maintenance, oil seals play a crucial role in ensuring the efficiency and longevity of mechanical systems. Among the various types of oil seals, the 25% 2035 7 oil seal stands out due to its unique specifications and applications. This article explores the design, functionality, and significance of the 25% 2035 7 oil seal, as well as its implications in modern engineering.

What is an Oil Seal?

An oil seal is a mechanical seal that is used to prevent the leakage of lubricants, such as oil and grease, while keeping contaminants out of machinery. These seals are designed to operate under specific conditions, and their effectiveness is crucial for the optimal performance of machines. The 25% 2035 7 oil seal refers to a seal with particular dimensional and material specifications that cater to certain applications.

Specification Breakdown

The designation 25% 2035 7 typically indicates a specific size and functionality of the oil seal. The numbers often refer to the dimensions in millimeters, allowing professionals to determine compatibility with various mechanical components. The designation might suggest attributes such as

- 25% This could refer to the thickness of the seal or the degree of flexibility it possesses, impacting its ability to withstand pressure and accommodate movements. - 2035 This likely represents the outer diameter or other critical dimensions, essential for ensuring a snug fit within the assembly. - 7 This number could indicate a specific design or series within a product line, indicating its material compatibility, temperature resistance, or other specialized features.

Materials and Design

25 35 7 oil seal

The effectiveness of the 25% 2035 7 oil seal is largely dependent on the materials used in its construction. Common materials include rubber, elastomers, and thermoplastics, each chosen for their unique properties

1. Nitrile Rubber (NBR) This material offers excellent resistance to oil and temperature variations, making it a common choice for oil seals used in automotive and industrial applications. 2. Fluoroelastomers (FKM) For applications involving aggressive fluids or higher temperatures, FKM seals provide superior chemical resistance and wear characteristics. 3. Polyurethane Known for its durability and flexibility, polyurethane seals can accommodate larger movements and are often used in dynamic applications.

The design of the oil seal also plays a significant role. Features like lip design and spring mechanisms can significantly enhance sealing performance, enabling the seal to adapt to various operating conditions and maintain a tight seal under pressure.

Applications

The 25% 2035 7 oil seal finds its applications across various industries. Some of the most notable include

- Automotive Industry Used in engines, transmissions, and differentials, oil seals prevent lubricant leaks, enhancing the performance and reliability of vehicles. - Manufacturing Equipment In factories, oil seals are critical for preventing contamination in motors, pumps, and hydraulic systems, thus ensuring a smoother operation and reducing downtime. - Aerospace In aviation, oil seals are crucial for maintaining the integrity of engines and hydraulic systems, where even minor leaks can lead to catastrophic failures.

Conclusion

The 25% 2035 7 oil seal is more than just a component; it embodies the intricate engineering required to maintain the functionality and integrity of complex mechanical systems. Understanding its specifications, materials, and applications can help engineers and technicians make informed decisions, ensuring that machinery operates efficiently and reliably. As industries continue to evolve, the importance of effective sealing solutions will remain paramount, making products like the 25% 2035 7 oil seal vital for the future of engineering and technology. In a world increasingly driven by machinery and automation, the seemingly simple oil seal plays a pivotal role in the reliability and longevity of modern mechanical systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories