டிசம்பர் . 11, 2024 09:09 Back to list

Similar Oil Seal Specifications for Enhanced Performance in Diverse Applications

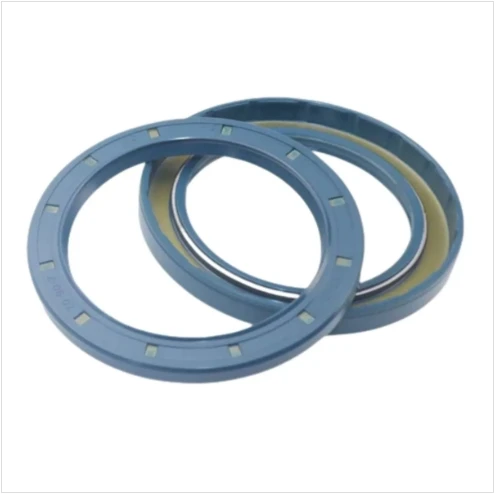

Understanding Oil Seals The 22% 40% 7% Ratio

Oil seals are essential components in various machinery and automotive applications. They are designed to prevent the leakage of lubricants, the entrance of contaminants, and the overall wear and tear on mechanical systems. One might wonder about the significance of the ratios such as 22%, 40%, and 7% in the context of oil seals. Let's break down these percentages in terms of application, design, and performance characteristics.

The Importance of Ratios in Oil Seals

In mechanical applications, ratios often represent the relative proportions of materials used, their operational efficiency, or their application context. In the case of oil seals, these figures could correspond to factors such as material composition, seal design, or functional performance metrics essential for specific uses.

22% might refer to the proportion of a specialized polymer compound used in the oil seal's manufacture. Many oil seals are made from elastomers such as nitrile rubber (Buna-N), fluorocarbon (Viton), or even silicone. Each material provides unique benefits, such as temperature resistance, oil compatibility, or flexibility. A seal constructed with 22% of a certain polymer might offer improved resilience against degradation due to heat or chemical exposure, making it particularly suited for high-performance applications in the automotive or manufacturing industry.

40% could represent the ratio of filler materials or reinforcements used in the oil seal's formulation. Fillers enhance the mechanical properties of the seal, such as tensile strength, abrasion resistance, and compressibility. A 40% filler content indicates a focus on durability, allowing the seal to withstand higher pressures and withstand harsh operational conditions. This would be especially crucial in applications where the seal is subject to constant movement or extreme temperature variations, such as in hydraulic machines or engines.

7% might highlight the proportion of processing aids or additives incorporated into the oil seal's design. These substances play a crucial role in manufacturing and performance, allowing for better mold release, improving flexibility, or enhancing compatibility with various lubricants. The careful selection and precise calculation of these additives can significantly affect the seal's longevity and efficiency, ensuring it performs optimally under varying conditions.

22 40 7 oil seal

Applications and Performance

The combined implications of the 22%, 40%, and 7% ratios suggest a well-engineered oil seal that balances flexibility, strength, and durability. In sectors like automotive engineering, aerospace, and heavy machinery, where seals are continuously subjected to challenging environments, such designs are invaluable.

For instance, in an automotive engine, oil seals are critical to maintaining proper lubrication within the engine components. If the seal fails due to inadequate material properties, it could lead to oil leaks, causing catastrophic engine failures and costly repairs. Therefore, understanding the ratios and what they signify is pivotal for manufacturers and engineers.

Additionally, these seals are not just confined to engines. They are used in gearboxes, pumps, and compressors, where maintaining the integrity of oil systems directly influences the efficiency and life span of the equipment.

Conclusion

In essence, the intricate details represented by the percentages of 22%, 40%, and 7% in the context of oil seals reflect a comprehensive approach to design and application. By delving into the composition and formulation of oil seals, we gain insights into their performance capabilities and operational efficiencies. Such understanding is essential for those involved in design and manufacturing, as it enables them to select or create the most fitting oil seals for their specific applications. Ultimately, the performance of machinery relies heavily on the reliability of these small yet crucial components, underscoring the importance of their meticulous design and manufacturing.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories