நவ் . 11, 2024 09:00 Back to list

20 35 7 oil seal

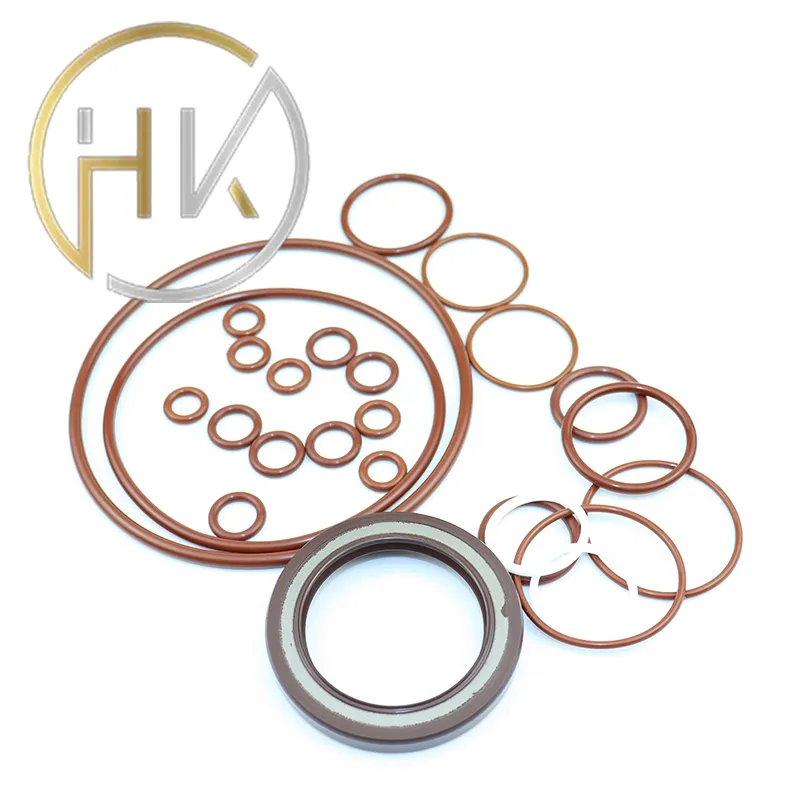

Understanding the 20% 2035 7 Oil Seal A Key Component in Fluid and Machinery Applications

In today's industrial landscape, the significance of effective sealing solutions cannot be understated. Among the myriad of seal types available, the 20% 2035 7 oil seal stands out as an essential component in machinery and fluid applications. This article delves into the characteristics, applications, and benefits of this particular oil seal, illustrating why it is crucial in modern engineering.

What is an Oil Seal?

Oil seals, often referred to as grease seals or rotary seals, are mechanical components designed to prevent the leakage of fluids while keeping contaminants out of critical machinery components. They are vital in various applications, from automotive engines to industrial machinery, ensuring the efficient operation of moving parts while minimizing maintenance costs.

Decoding the 20% 2035 7 Oil Seal

The designation 20% 2035 7 can be likened to a coding system that conveys specific details about the oil seal's design, material, and application requirements. The 20% likely indicates a percentage of certain properties, such as resistance to temperature or pressure, which is critical in ensuring the oil seal performs optimally in its designated environment.

The 2035 may refer to the dimensions of the seal, such as its outer diameter, inner diameter, and thickness, essential for compatibility with respective machinery. Accurate dimensions ensure a proper fit, minimizing the risk of leakage and enhancing the seal's lifespan.

Finally, the 7 could signify a specific design feature or material grade, denoting its resistance to various environmental challenges. For instance, seals made from high-quality elastomers or thermoplastics can withstand extreme temperatures and pressures, making them ideal for demanding applications.

Applications of the 20% 2035 7 Oil Seal

The versatility of the 20% 2035 7 oil seal makes it applicable across various industries. These include

1. Automotive In vehicles, oil seals are often used in engines and transmissions to prevent oil leakage and protect internal components from dirt and moisture.

2. Industrial Machinery Manufacturing equipment frequently employs oil seals to ensure efficient operation by preventing lubricant loss and keeping out harmful contaminants.

20 35 7 oil seal

3. Aerospace In the aerospace sector, oil seals are crucial for maintaining the integrity of hydraulic and fuel systems, thereby ensuring safety and performance.

4. Agriculture Agricultural machinery, such as tractors and combines, relies on oil seals to protect critical parts, ensuring smooth operations in challenging environments.

5. Marine In marine applications, oil seals help safeguard machinery from seawater intrusion, prolonging operational life and reducing maintenance needs.

Benefits of Using the 20% 2035 7 Oil Seal

Investing in quality oil seals, like the 20% 2035 7, offers several advantages

- Prevent Leakage By providing a robust barrier against oil and fluid loss, these seals help maintain system efficiency and pressure. This is crucial for both performance and safety in many applications.

- Reduce Contaminants Oil seals prevent dirt, dust, and other contaminants from infiltrating machinery, which can lead to premature wear and costly repairs.

- Versatile Design The specifications associated with the 20% 2035 7 oil seal enable it to be used in various applications, making it a cost-effective choice for multiple industries.

- Longevity High-quality materials and precise engineering contribute to the durability and longevity of these seals, reducing the frequency of replacements and maintenance.

Conclusion

The 20% 2035 7 oil seal exemplifies the intricate engineering that goes into ensuring the efficient performance of machinery across different sectors. Its robust design, resilience against harsh conditions, and multifunctional capabilities make it an indispensable component in maintaining the integrity of systems and machinery. By choosing the right oil seal, businesses can enhance operational efficiency, reduce downtime, and ultimately, drive success in their respective industries. Investing in reliable sealing solutions like the 20% 2035 7 oil seal is an investment in the future of technical excellence and operational reliability.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories