Desemba . 14, 2024 14:26 Back to list

seal kit pump

The Essential Role of Seal Kit Pumps in Industrial Applications

In various industrial applications, reliable and efficient operation of machines is crucial. Among the many components that ensure smooth functioning, seal kit pumps play a vital role. These specialized pumps are designed to maintain the integrity of hydraulic systems, preventing leaks and ensuring optimal performance. This article explores the anatomy, function, and applications of seal kit pumps while highlighting their importance in various industries.

Understanding Seal Kit Pumps

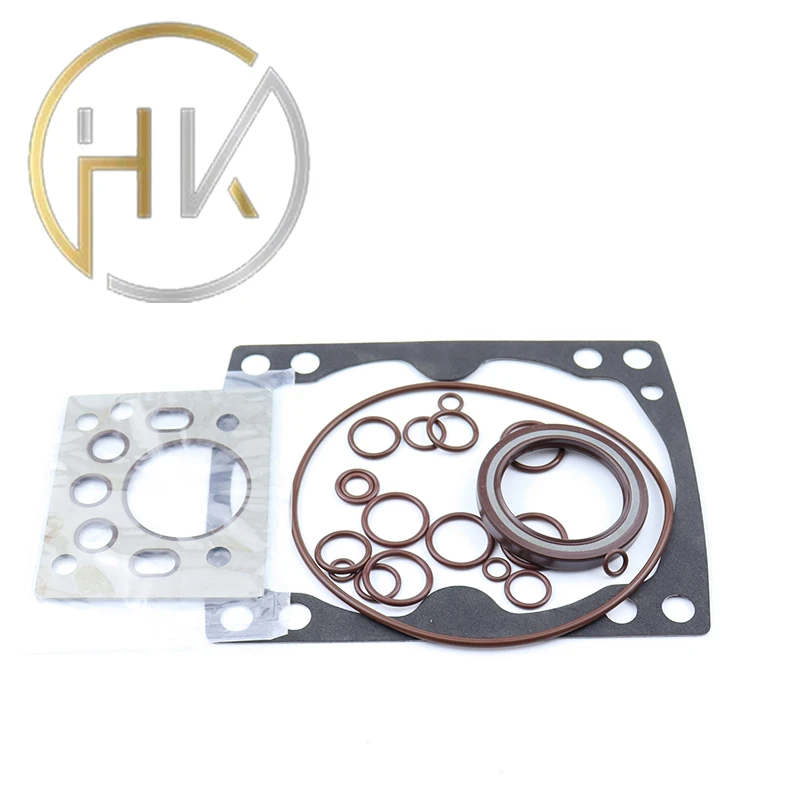

A seal kit pump is essentially a hydraulic pump that is equipped with specialized seals and gaskets. These seals are designed to create a tight barrier, preventing the escape of hydraulic fluid that is essential for the pump’s operation. The seal kit typically includes O-rings, gaskets, and various other components that work together to make the pump efficient and leak-proof.

These pumps can be found in various designs, including gear pumps, piston pumps, and diaphragm pumps, depending on the application requirements. Each type of pump has its advantages and is selected based on the specific needs of the machinery it serves.

The Function of Seal Kit Pumps

The primary function of seal kit pumps is to facilitate the movement of hydraulic fluid while minimizing the risk of leaks. Hydraulic systems rely on pressurized fluid to transmit force, and any loss of this fluid can lead to a decrease in performance or equipment failure. Seal kit pumps ensure that the hydraulic medium remains contained, allowing for efficient energy transfer.

Moreover, seal kits also provide protection against contaminants such as dirt, dust, and water, which can degrade fluid quality and negatively impact the performance of the hydraulic system. By preventing these contaminants from entering the pump, seal kits contribute to the longevity and reliability of industrial machinery.

Applications of Seal Kit Pumps

seal kit pump

Seal kit pumps are widely used across different sectors, including construction, manufacturing, and automotive industries. In construction, these pumps are integral to hydraulic machinery like excavators, bulldozers, and loaders. They help in the smooth operation of these machines, enabling them to perform heavy-duty tasks efficiently.

In the manufacturing sector, seal kit pumps are crucial for machines that require precise control of hydraulic fluid. Whether in injection molding, metal forming, or assembly lines, these pumps ensure that operations run smoothly, reducing downtime and maintenance costs.

The automotive industry also benefits from seal kit pumps, as they are used in various applications ranging from power steering systems to automatic transmissions. In these systems, reliable pressure generation and maintenance are imperative for safety and performance. Seal kit pumps help achieve that reliability.

The Importance of Quality Seal Kits

The performance of seal kit pumps heavily depends on the quality of the seal kits themselves. Low-quality seals can lead to premature wear, leaks, and even catastrophic failure of the pump. Therefore, investing in high-quality seal kits is crucial for maintaining the operational efficiency of hydraulic systems.

Regular maintenance and monitoring of seal kit pumps are also essential. Over time, seals can deteriorate due to wear and tear, temperature fluctuations, and contamination. Regular inspection and replacement of worn seals can prevent significant failures and prolong the life of the pump.

Conclusion

Seal kit pumps are indispensable components in a multitude of industrial applications. They ensure that hydraulic systems function efficiently, minimizing leaks, and protecting against contaminants. As industries continue to evolve and demand higher efficiency and reliability, the role of seal kit pumps becomes ever more critical. By investing in quality seal kits and maintaining these systems diligently, industries can enhance their operational performance, reduce costs, and ensure the safety and functionality of their machinery. In a world where efficiency and reliability are paramount, seal kit pumps stand as a cornerstone of modern industrial operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories