Januari . 22, 2025 03:55 Back to list

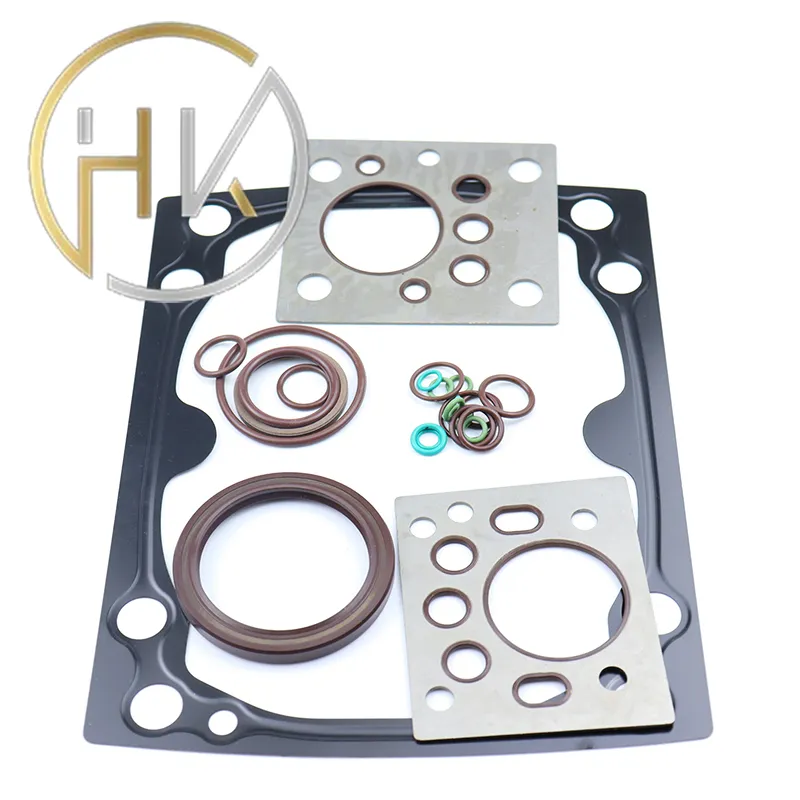

wiper seals

2. Cylinder Disassembly Begin by removing the hydraulic cylinder from its mounting. Carefully disassemble the cylinder, starting with the end cap or retaining ring. This provides access to the piston rod and wiper seal. 3. Removing the Old Seal With the rod exposed, the old wiper seal can be removed. Use a seal removal tool to avoid damaging the rod or seal groove. It's vital to ensure that all seal remnants are cleared away to prevent contamination of the new seal. 4. Inspecting and Cleaning Conduct a thorough inspection of the rod and cylinder casing for any signs of damage or wear. Clean the area meticulously to ensure no debris is present that could compromise the new seal's integrity. 5. Installing the New Seal Fit the new wiper seal into the groove. Ensure it's seated evenly and facing the correct direction, as incorrect installation can impair functionality and lead to early failure. Lubricating the seal beforehand can ease the installation process and enhance seal life. 6. Reassembling the Cylinder Once the new seal is in place, carefully reattach the end cap or retaining ring and reassemble the cylinder. Re-mount the cylinder onto the machine after verifying all components are securely fastened. 7. Testing for Leaks After reassembly, gradually repressurize the system, monitoring for any leaks around the new seal. This step ensures the replacement has been successful and the system operates smoothly. Enhancing Longevity and Performance Post-Replacement To maximize the lifespan of the new wiper seal and maintain hydraulic cylinder performance, adhere to a rigorous maintenance routine. Regular system checks and timely fluid replacement can significantly reduce wear and tear on seals and other components. Moreover, investing in high-quality seals from reputable manufacturers further assures reliability and trustworthiness. In the realm of hydraulic systems, expertise in maintaining key components like the wiper seal not only ensures the machinery's optimal performance but also exemplifies a commitment to professional standards and safety. By following industry best practices when replacing these seals, businesses can uphold their authoritative stance in the sector while fostering trust with clients and stakeholders.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories