Novemba . 10, 2024 05:51 Back to list

Understanding the Benefits and Applications of PU Wiper Seals for Various Industries

Understanding PU Wiper Seals Composition, Benefits, and Applications

In the realm of industrial applications, the efficiency and longevity of equipment play crucial roles in determining operational success. One essential component that can significantly impact performance is the wiper seal. Among the various materials used for manufacturing wiper seals, polyurethane (PU) has gained considerable popularity due to its superior properties. This article delves into the characteristics, advantages, and applications of PU wiper seals in diverse industries.

What are Wiper Seals?

Wiper seals are essential components commonly found in hydraulic and pneumatic systems. Their primary function is to prevent external contaminants such as dust, dirt, and moisture from entering the cylinder and affecting the internal components. Moreover, they help retain lubrication, ensuring smooth operation and minimizing wear. Wiper seals are typically integrated into various equipment, including construction machinery, automotive systems, and manufacturing equipment.

The Advantages of PU Wiper Seals

1. Durability PU material is known for its excellent abrasion and tear resistance, making PU wiper seals particularly durable. This property enables them to withstand harsh operating environments and prolong the lifespan of the equipment they protect.

2. Chemical Resistance PU wiper seals can resist a wide range of chemicals, oils, and greases. This characteristic is vital in industries such as automotive and manufacturing, where exposure to various substances is commonplace.

3. Temperature Tolerance Polyurethane can perform well in both high and low-temperature conditions, providing versatility in a range of environments. PU wiper seals maintain their effectiveness even when subjected to extreme temperatures, making them suitable for diverse applications.

4. Low Friction PU wiper seals exhibit low friction characteristics, which enhances the efficiency of machinery. Reduced friction leads to less heat generation and minimizes power consumption, contributing to overall operational efficiency.

5. Customization PU wiper seals can be engineered to meet specific requirements, including size, shape, and hardness. This flexibility allows manufacturers to create tailored solutions to fit various needs across different industries.

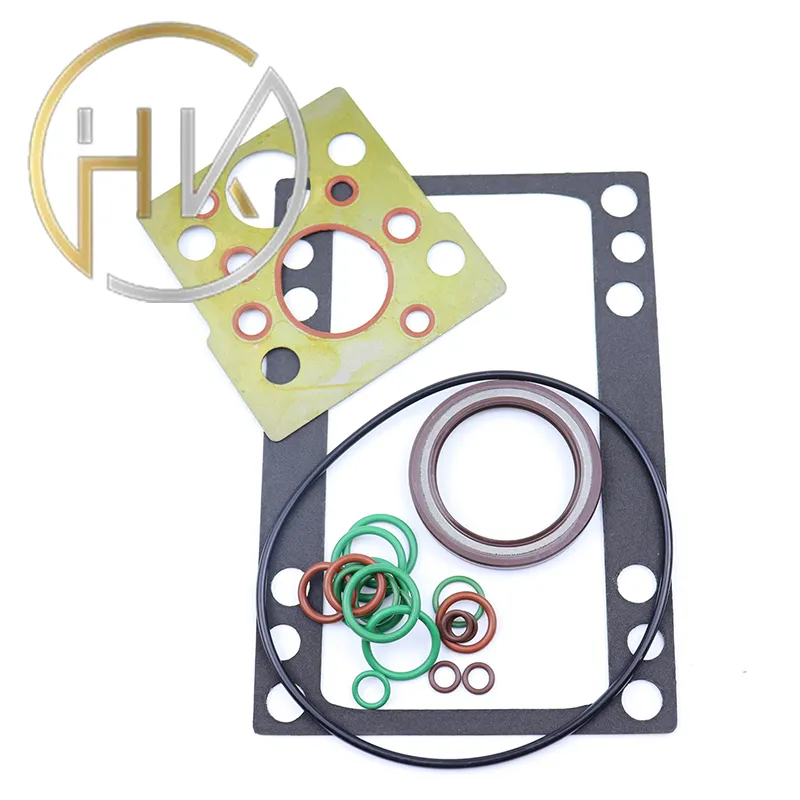

pu wiper seal

Applications of PU Wiper Seals

PU wiper seals are employed in multiple sectors due to their versatility and performance characteristics. Some key applications include

- Construction Machinery In hydraulic systems, PU wiper seals protect equipment such as excavators, loaders, and cranes from dirt and particles, ensuring consistent operation over time.

- Automotive Industry In vehicles, PU wiper seals are commonly used in hydraulic systems, steering systems, and suspension components, where they help maintain fluid integrity and prevent contamination.

- Manufacturing Equipment In the manufacturing sector, PU wiper seals are utilized in machinery that operates under high pressure and speed, ensuring optimal performance and a reduction in maintenance costs.

- Aerospace and Defense In aerospace applications, where reliability and safety are paramount, PU wiper seals are employed in hydraulic systems and landing gear, where their ability to withstand extreme conditions is essential.

- Medical Devices In the medical field, the cleanliness and reliability of equipment are crucial. PU wiper seals are used in various devices to prevent contamination and maintain the integrity of sensitive mechanisms.

Conclusion

In summary, PU wiper seals represent a significant advancement in sealing technology. Their durability, chemical resistance, temperature tolerance, low friction, and customizable options make them a preferred choice across various industries. As organizations continue to prioritize efficiency and reliability, the role of PU wiper seals in protecting valuable equipment and ensuring smooth operations will only become more prominent. By investing in high-quality PU wiper seals, businesses can enhance performance, reduce maintenance costs, and ultimately achieve greater operational success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories